Maintenance

LXT-220 DO

Teledyne Analytical Instruments

52

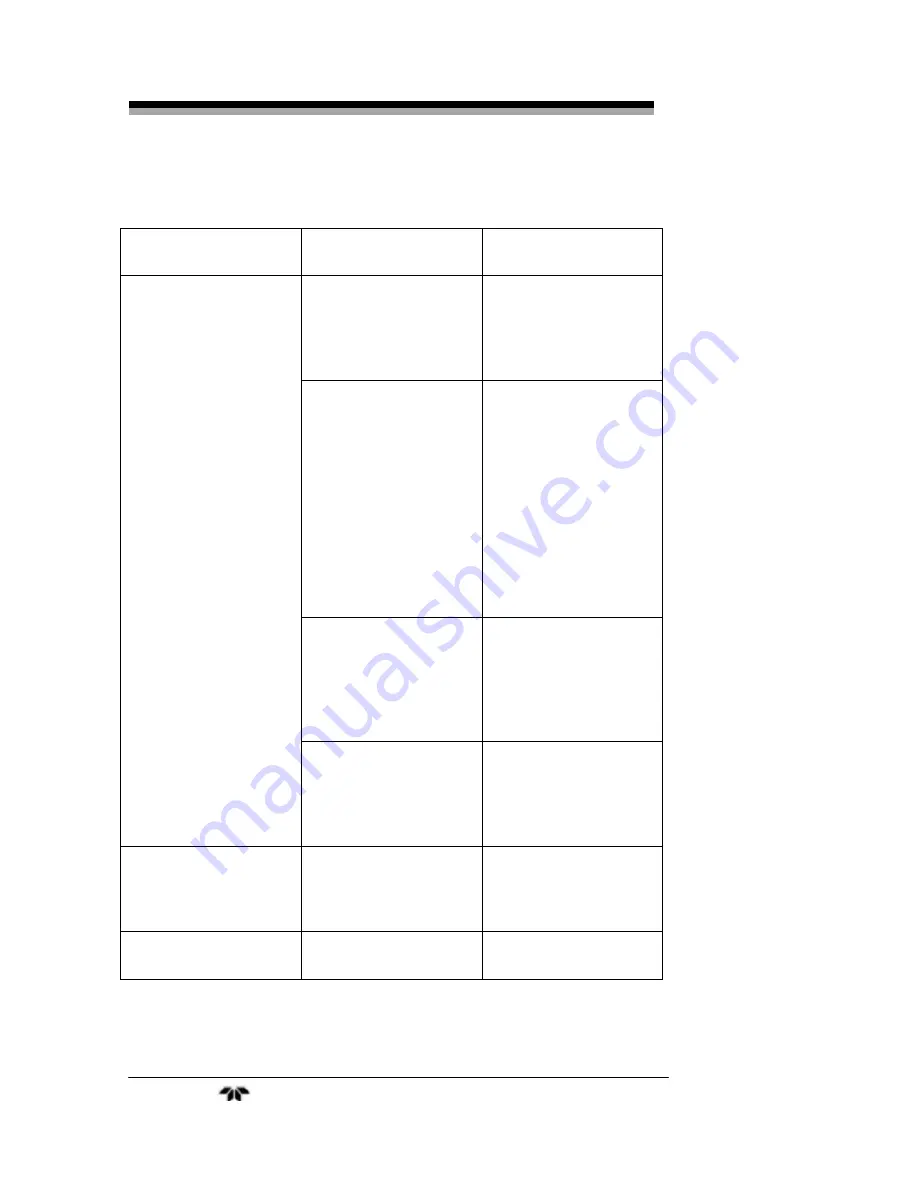

Table 4-1: Troubleshooting

SYMPTOM

POSSIBLE CAUSES

SUGGESTED

ACTION

No power to the

instrument.

Check power supply

to be sure the correct

voltage is being

supplied to the

transmitter.

Contrast level is set

too low.

Set contrast level to a

higher value.

Because the contrast

menu is always the

top menu, it can be

reached by pressing

the upper MENU

SELECTION key at

least 12 times. Enter

the calibrate mode

and increase the

value.

Sensor or signal

conditioner has a

short that draws too

much power from the

transmitter.

Check the sensor for

proper operation. To

verify, disconnect all

sensor wires and

cycle power off, then

on.

The LCD does not

display.

The PROM has not

been properly

installed in the socket.

Check orientation of

the PROM to the

socket. Make sure the

pins are fully inserted

and are not bent.

Readings are not

linear at the low end

of the range.

The sensor range is

not compatible with

the instrument.

Verify the sensor

range. Install a

sensor with the

correct range.

Erratic readings.

Air bubble in sensor.

Check orientation of

sensor.