Installation

Vision G2 Testers User Guide—74-108-800 Rev. H—12 June 2019

41 of 158

Liquid Line Connections

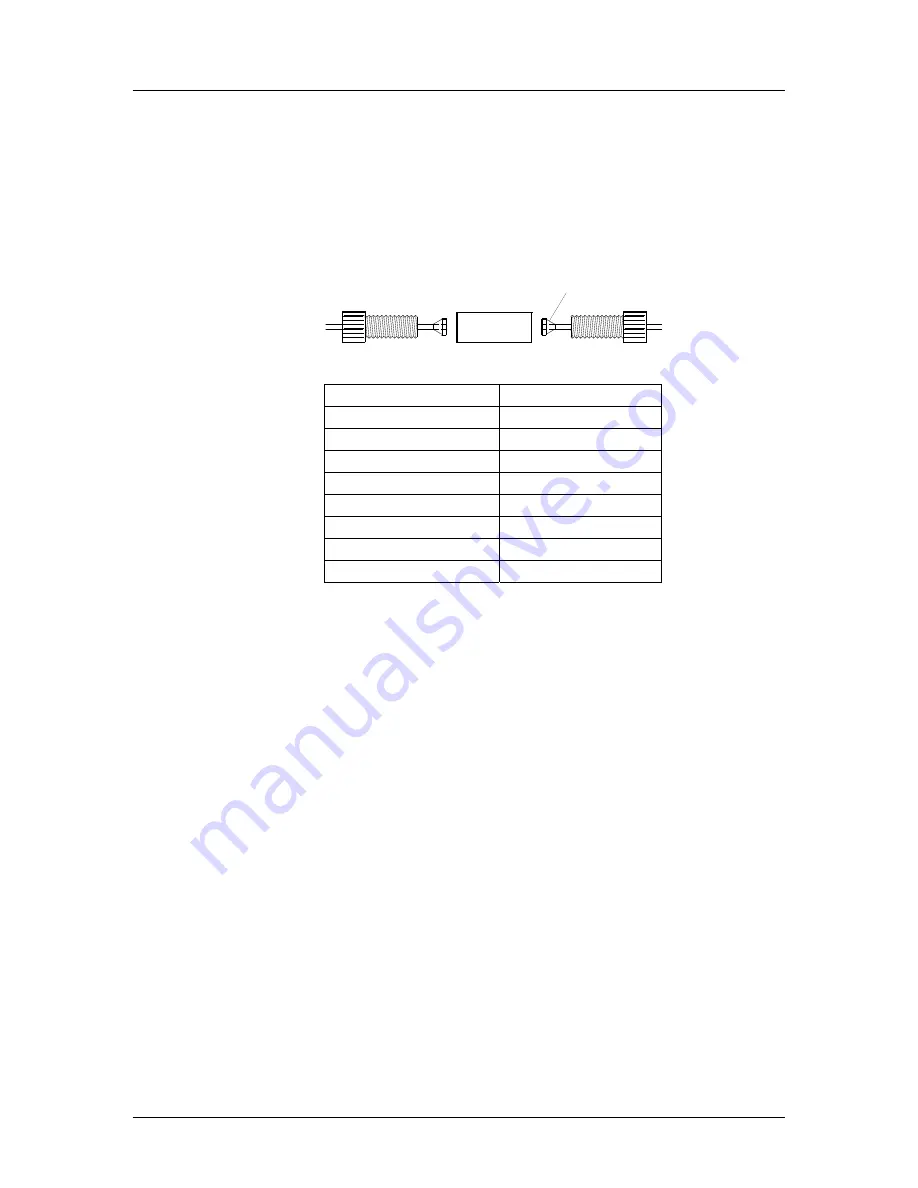

Sample line connections are made by connecting the six or

eight liquid tubes from the Vision AutoPlus/AutoFill or other

autosampler to the dissolution tester. These are numbered and

color-coded for easy identification. They can be connected with

nuts, unions, and ferrules as shown in the figure below:

Position

Fitting Color

1

Black

2

Red

3

White

4

Yellow

5

Green

6

Blue

7

Clear

8

Purple

Fig. C-12 Liquid Line Connections

Security

The Vision tester can be configured to require users to log in

and allows for tracking of any changes made to the protocol.

The security system allows for 25 users when using firmware

versions below 2.50 and 50 users for versions 2.50 and above.

Firmware versions below 2.70 offer two levels of users

(managers and operators) with fixed permissions:

Managers are given full access to the unit and allowed to

make any changes to the system as required, with all

these changes being tracked by the software. All users

can be configured as managers for full control of the

Vision tester. One manager is required by the software.

Hanson is installed as a manager from the factory. The

default password for the Hanson manager is 0000.

Operators are permitted to run tests but are not allowed to

make changes to protocols or other system settings. Not

all users can be configured as operators; the software

requires at least one user be configured as a manager.

UNION

NUT

FERRULE

Summary of Contents for VISION G2 CLASSIC 6

Page 1: ...VISION G2 CLASSIC 6 AND ELITE 8 DISSOLUTION TESTERS USER GUIDE 74 108 800 Rev H 12 June 2019...

Page 148: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 147 of 158...

Page 149: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 148 of 158...

Page 150: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 149 of 158...

Page 151: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 150 of 158...

Page 152: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 151 of 158...

Page 153: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 152 of 158...

Page 154: ...Appendix D Reports Vision G2 Testers User Guide 74 108 800 Rev H 12 June 2019 153 of 158...