Programmable Sweep Instruction Manual

CONFIGURATION

telemark.com

32 of 58

Rev 1.0.0

20

19

0

1

0

0

1

1

21

20

0

1

0

1

0

0

22

21

0

1

0

1

0

1

23

22

0

1

0

1

1

0

24

23

0

1

0

1

1

1

25

24

0

1

1

0

0

0

26

25

0

1

1

0

0

1

27

26

0

1

1

0

1

0

28

27

0

1

1

0

1

1

29

28

0

1

1

1

0

0

30

29

0

1

1

1

0

1

31

30

0

1

1

1

1

0

32

31

0

1

1

1

1

1

-

32

1

0

0

0

0

0

1 = CLOSED, 0 = OPEN

* Note in

“Binary 1=00001” mode, 00001 and 00000 both equal one.

5.2.3 Beam in Pocket (BIP)

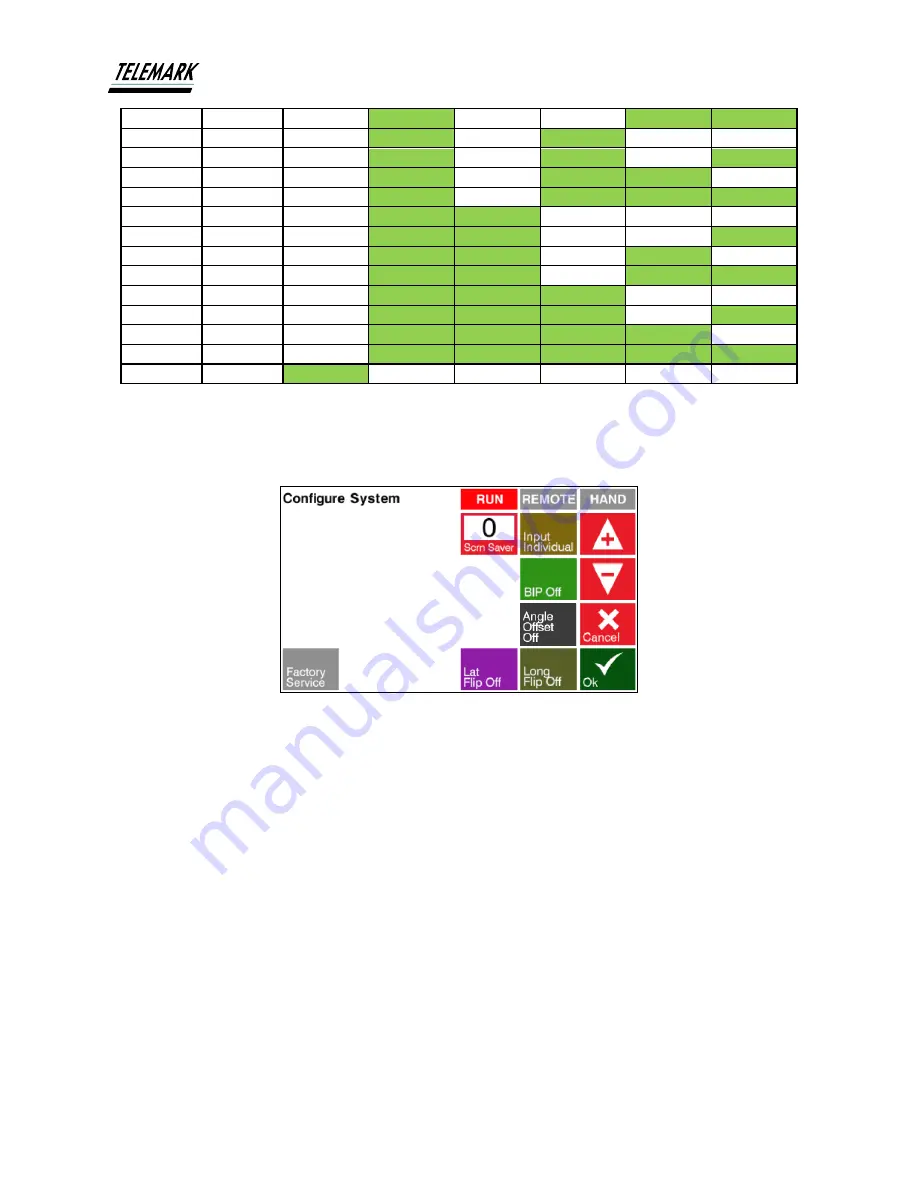

Figure 5-3, Beam in Pocket Setup

Beam in pocket is used for some non-Telemark e-beam sources that require lateral or

longitudinal signal that the beam is in the pocket.

The output BIP contacts close when the current on the BIP axis coil is greater than + or

- 500 mA. See chapter 3 for the 25 pin connector connections for the following three

modes:

1.

BIP Off

–

BIP relay not activated (Telemark E-beam Sources)

2.

BIP Lat

–

BIP relay activated when current on lateral axis is greater than + or -

500 mA.

3.

BIP Long

–

BIP relay activated when current on longitudinal axis is greater than

+ or - 500 mA.