BenchMark

®

200/BM470 Marking System

34743A

3 of 8

BENCHMARK200 MARKING HEAD (continued)

Marking Noise

Sound pressure-level tests were conducted on the BenchMark200

Marking System using a Larson-Davis Model 710 sound pressure

meter while dry firing the marker at a 50% duty cycle. The

maximum sound pressure level during the test cycle was measured

at 70.9 dB. The time-weighted average (LEQ) using the 3 db rule

without threshold was 61.8 dB. Typical applications average a

20% to 30% duty cycle where the time-weighted average would

not exceed 70 dB(A).

The sound pressure-level tests were carried out under controlled

conditions, imitating as closely as possible, predicted normal

operation. However, noise level is heavily dependent on the part

being impacted. Conditions such as the material being marked, the

rigidity of the work piece, machine settings, ambient noise, etc.,

may all vary when in operational use. Such variables will alter the

actual noise level.

Despite detailed guidance provided with each machine, variable

operating conditions are beyond the control of Telesis. The

responsibility of establishing safe working levels of use remains

with the end user. Accordingly, you should conduct your own

sound pressure-level tests for your application while marking

actual work pieces.

Pin Life

Pin life depends largely on the type of material being marked, how

hard or abrasive it is, and the required marking depth. On typical

metals with a hardness of Rockwell Rb47, marking at a depth of

.127 mm (.005 in.), carbide pins average approximately 9 million

impressions before needing sharpened.

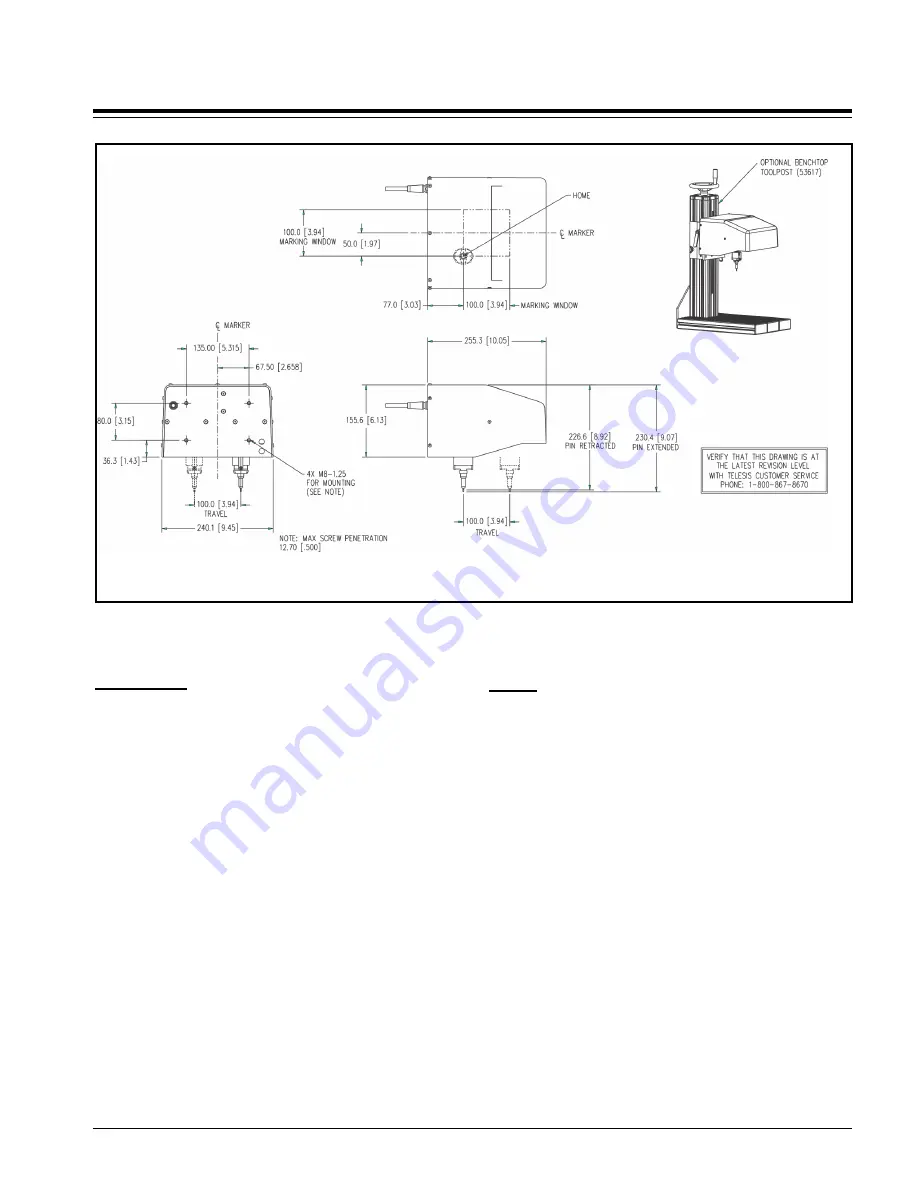

BenchMark200 Marking Head Dimensions