- 38 -

3/$66(5,1*$9+-/(0(1),*%

5HJXOHULQJDY\WWHUEnQG)LJ%

+MHOPHQ Pn UHJXOHUHV IRU n EHVN\WWH ¡\QHQH RJ DQVLNWHW Sn HIIHNWLYW YLV L O¡SHW DY

VYHLVLQJHQ

3RVLVMRQHQYHGEnQGHWIRUDQRJEDNNDQUHJXOHUHVPDQXHOWIRUSHUIHNWWLOSDVQLQJWLO

KRGHWVVW¡UUHOVH

9ULSnNQRWWHQYHGHQNHOWHPRGHOOHUPnGXWU\NNHSnNQRWWHQIRUnNXQQHYULSnGHQ

IRUnWLOSDVVHEnQGHWWLOKRGHW

5HJXOHULQJDYK¡\GHQYHG\WWHUEnQGHW)LJ%

+¡\GHQ NDQ UHJXOHUHV VOLN DW EnQGHW SODVVHUHV UHWW RYHU ¡\HQEU\QHQH VNUX WLO HOOHU

VNUXXWGHWRJUDGHUWHUHLPHQHSODVVHUWSnGHQ¡YUHGHOHQDYKRGHW

5HJXOHULQJDYDYVWDQGHQPHOORPDQVLNWHWRJ¿OWHUHW)LJ%

6NUXO¡VWGH\WUHNQRWWHQHRJGUDGHPIUHPRYHUHOOHUEDNRYHUIRUnQn¡QVNHWSRVLVMRQ

RJVNUXGHUHWWHUWLOSnQ\WW

5HJXOHULQJDYYLQNOLQJHQ)LJ%

'HQ LGHHOOH YLQNOLQJ DY KMHOPHQ RJ YLQNOLQJHQ YHG ¡\QHQH HU YLQNHOUHWWH Sn

¿OWHURYHUÀDWHQ)RUnUHJXOHUHYLVQLQJVYLQNHOHQPnGXVNUXO¡VWNQRWWHQHSnEHJJH

VLGHQHDYKMHOPHQRJVWLOOHLQQ¡QVNHWYLQNOLQJ'HUVRPGHWLNNHHUPXOLJn¿QQH¡QVNHW

YLQNOLQJ Pn GX WU\NNH Sn NQDSSHQH Sn VLGHQ RJ À\WWH PDUN¡UHQH VDPWLGLJ VOLN DW

KMHOPHQRYHUVNULGHUJUHQVHQIRUIRUKnQGVLQQVWLOWYLQNOLQJ

0217(5,1*

8WI¡UPRQWHULQJHQVRPYLVWSnWHJQLQJHQ

),*$

6HWWLQQEDWWHULHUDYW\SH&57:&57:L¿OWHUHWI¡UGXEUXNHU

KMHOPHQ

),*&

%58.

+MHOPHQ Pn DOOWLG RJ NXQ EUXNHV WLO n EHVN\WWH DQVLNWHW RJ ¡\QHQH XQGHU VYHLVLQJ

+MHOPHQ RJ GHUPHG RPUnGHW YHG GHW YLVXHOOH ¿OWHUHW XQGHU VYHLVLQJ Pn KROGHV Vn

Q UW¡\QHQHVRPPXOLJVOLNDWGLVVHEHVN\WWHVPRWO\VVWUnOHQHRJHYHQWXHOWGUnSHU

med smeltet metall.

)¡U GX VWDUWHU VYHLVHSURVHVVHQ Pn GX NRQWUROOHUH DW ¿OWHUHW RJ GH JMHQQRPVLNWLJH

HNVWHUQHRJLQWHUQHEHVN\WWHOVHQHHUULNWLJSODVVHUW

5HJXOHU ³6KDGH´ O\VJUDGHULQJHQ L PRGHOOHQH KYRU GHWWH HU PXOLJ EDVHUW Sn

VYHLVHVWU¡PPHQRJVYHLVHPnWH

I

WDEHOO

VWnU WDOOHQH IRU ³VKDGH´ O\VJUDGHULQJ RSSI¡UW VRP DQEHIDOHV IRU VYHLVLQJ

PHG HOHNWULVN EXH RJ IRU SURVHG\UHU IRU YDQOLJ EUXN RJ IRU XOLNH LQWHQVLWHWQLYnHU DY

VYHLVHVWU¡P .RQWUROOHU DW VWU¡PLQWHQVLWHWHQ RJ VYHLVHSURVHG\UHQ HU WLOSDVVHW GHQ

EHVN\WWHQGHO\VJUDGHULQJHQYHG¿OWHUHW

5HJXOHU ³6HQVLWLYLW\´ I¡OVRPKHWHQ L PRGHOOHQH GHU GHWWH HU IRUXWVHWW EDVHUW Sn

O\VLQWHQVLWHWHQYHGVYHLVHEXHQ

5HJXOHU³GHOD\WLPHLPRGHOOHQHGHUGHWWHHUIRUXWVHWWIRUnVWLOOHLQQIRUVLQNHOVHVWLGHQ

IRURYHUJDQJIUDP¡UNWLOVWDQGWLOO\VWLOVWDQGHWWHUDYEUXGGDYEXHQRJEDVHUWSnGHOHQV

O\VVW\UNH

)¡UEUXNPnGXXWI¡UHHQWHVWPHGHQVYHLVHEXH

+MHOPHQL³*5,1'´SRVLVMRQNDQEUXNHVWLOVOLSLQJ

(WWHU EUXN RJ XDQVHWW I¡U GHQ OHJJHV Sn SODVV HWWHU HQGW DUEHLG Pn GX NRQWUROOHUH

KMHOPHQ IRU n VH DW GHQ HU KHO RJ IMHUQH HYHQWXHOOH GUnSHU PHG VPHOWHW PHWDOO VRP

PnWWH¿QQHVSnVLNWV¿OWHUHWVRPNDQUHGXVHUHVLNWHQYHGVHOYH¿OWHUHW

+MHOPHQPnOHJJHVSnSODVVSnHQVOLNPnWHDWSHUPDQHQWHGHIRUPDVMRQXQQJnVHOOHU

DWGHWEHVN\WWHQGHVLNWV¿OWHUHWNDQ¡GHOHJJHV

9('/,.(+2/'2*5(1*-5,1*

6NLIWXWEDWWHULHQHQnUOHGO\VHW/2:%$7WHQQHVGHUVRPGHWWH¿QQHV

),*&

6NLIW XW GHQ HNVWHUQHLQWHUQH JMHQQRPVLNWLJH EHVN\WWHOVHVSODWHQ YHG ¿OWHUHW L

WLOIHOOH GHW IRUHNRPPHU ¡GHOHJJHOVHU ULSHU VNnU HOOHU GHIRPHULQJHU 2SSYDUPHGH

EHVN\WWHOVHUVHWWHUJRGVLNWWLOGHWVRPGXGULYHUSnPHGLIDUHRJVHQNHUKMHOPHQV

EHVN\WWHOVHVQLYnWLOHWIDUOLJQLYn

5HQJM¡U RIWH RYHUÀDWHQ YHG GHW VHOYIRUP¡UNHQGH ¿OWHUHW RJ EHVN\WWHOVHVSODWHQH

PHGHQP\NNOXWPHGLNNHDJJUHVVLYHUHQJM¡ULQJVPLGOHUIRUHNVHPSHOSURGXNWHUIRU

YDVNLQJDYYLQGXHULNNHKHOOSURGXNWHWGLUHNWHSn¿OWHUHW

.RQWUROOHUMHYQOLJDWVROFHOOHQHRJVHQVRUHQHLNNHKDUEOLWWEORNNHUWHOOHUGHNNHWWLODY

VNLWW+YLVGHWWHHUWLOIHOOHPnGXUHQJM¡UHGHPPHGHQP\NNOXWVRPHYHQWXHOWHUOHWW

IXNWHWPHGHWSURGXNWIRUYDVNLQJDYYLQGXHULNNHKHOOSURGXNWHWGLUHNWHSn¿OWHUHW

5HQJM¡URJGHVLQ¿VHUKMHOPHQNXQPHGYDQQRJVnSHHOOHUXDQVHWWPHGO¡VHPLGGHOIULH

SURGXNWHU %UXNHQ DY NMHPLVNH O¡VHPLGOHU ¡GHOHJJHU KMHOPHQV XWVHHQGH RJ KDQ

¡GHOHJJHGHQKHOW

(Q JRG JHQHUHOO SOHLH DY KMHOPHQ JM¡U GHW PXOLJ n UHGXVHUH KMHOPHQV IRUHOGHOVH

WLO HW PLQLPXP EnGH L IRUKROG WLO EUXN DY VHOYH KMHOPHQ RJ L IRUKROG WLO KMHOPHQV

NRPSRQHQWHU

5HQJM¡U RIWH RYHUÀDWHQ YHG ¿OWHUHW PHG HQ P\N NOXW PHG LNNHDJJUHVVLYH

UHQJM¡ULQJVPLGOHUIRUHNVHPSHOSURGXNWHUIRUYDVNLQJDYYLQGXHULNNHKHOOSURGXNWHW

GLUHNWHSn¿OWHUHW

.RQWUROOHUMHYQOLJDWVROFHOOHQHRJVHQVRUHQHLNNHKDUEOLWWEORNNHUWHOOHUGHNNHWWLODY

VNLWW+YLVGHWWHHUWLOIHOOHPnGXUHQJM¡UHGHPPHGHQP\NNOXWVRPHYHQWXHOWHUOHWW

IXNWHWPHGHWSURGXNWIRUYDVNLQJDYYLQGXHULNNHKHOOSURGXNWHWGLUHNWHSn¿OWHUHW

325%/(0(52*/61,1*(5

,O¡SHWDYEUXNDYKMHOPHQNDQGHWRSSVWnYDQOLJHSUREOHPHUVRPKHUVWnURSSI¡UWPHG

WLOK¡UHQGHO¡VQLQJHU

)LOWHUHWEOLULNNHP¡UNWHOOHUHUXVWDELOWLRYHUJDQJHQIUDO\GWLOVWDQGWLOP¡UNWLOVWDQGRJ

RPYHQGW

0XOLJO¡VQLQJ

'HQHNVWHUQHJMHQQRPVLNWLJHEHVN\WWHOVHQYHG¿OWHUHWHUVNLWWHQHOOHU¡GHODJWVNLIW

XWGHQHNVWHUQHJMHQQRPVLNWLJHEHVN\WWHOVHQ

6HQVRUHQHHUVNLWQHUHQJM¡UVHQVRURYHUÀDWHQH

1LYnHWYHGVYHLVHVWU¡PPHQHUIRUODYW¡NI¡OVRPKHWHQGHUVRPGHQQH¿QQHVHOOHU

VNLIWXWKMHOPHQPHGHQDQQHQPHGHW¿OWHUVRPHUHJQHWWLOIRUPnOHW

6DNWHNRPPXWHULQJ

0XOLJO¡VQLQJ

)RUODYGULIWVWHPSHUDWXULNNHEUXNHQWHPSHUDWXUVRPHUODYHUHHQQ&)

'nUOLJVLNW

0XOLJO¡VQLQJ

'HQHNVWHUQHRJHOOHULQGUHEHVN\WWHOVHQYHG¿OWHUHWRJHOOHU¿OWHUHWHUVNLWWHQHOOHU

¡GHODJWUHQJM¡UGHVNLWQHNRPSRQHQWHQHRJVNLIWXWGHVRPHU¡GHODJW

'HW¿QQHVLNNHQRNO\VLRPUnGHWUXQGWV¡UJIRUHQEHGUHEHO\VQLQJDYRPUnGHW

UXQGW

1XPPHUHWYHGJUDGHULQJVVNDODHQHULNNHVWLOWULNWLJLQQYHOJULNWLJYHUGLLPRGHOOHQH

GHUGHWWHHUPXOLJ

ADVARSEL!

'HUVRP IHLOIXQNVMRQHQH EHVNUHYHW RYHQIRU LNNH NDQ O¡VHV Pn GX

XPLGGHOEDUWDYEU\WHEUXNHQDYKMHOPHQRJWDNRQWDNWPHGQ UPHVWH

IRUKDQGOHU

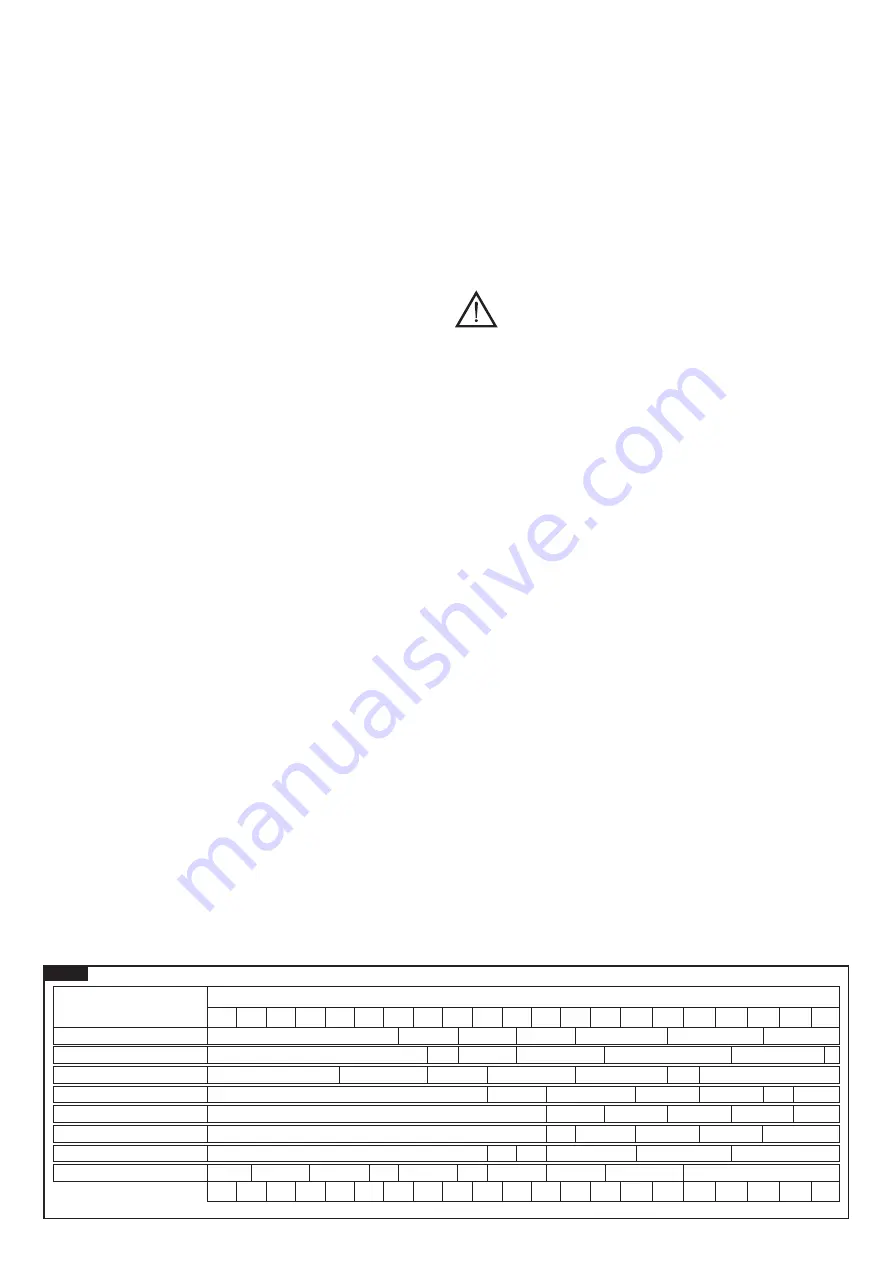

MAG

TIG

Sveiseprosedyre og

tilhørende teknikk

Kledde elektroder

MIG på tunge metaller (*)

MIG på lette metaller

Luft-bue skjæring

Plasma-jet skjæring

Buesveising med mikroplasma

Spenning i Ampere

Antall graderinger (shades) og anbefalt bruk for buesveising

(*) Utrykket "tunge metaller" gjelder stål, stållegeringer, kobber og legeringer etc.

TAB. 1

12

1.5

8

8

10

4

5

6

7

8

9

10

11

9

10

11

12

13

11

12

13

14

15

8

10

11

12

13

14

9

10

11

12

13

14

9

10

11

12

13

9

10

11

12

13

14

9

10

11

12

13

14

6

10

15

30

40

60

70 100 125 150 175 200 225 250 300 350 400 450 500 600

1.5

6

10

15

30

40

60

70 100 125 150 175 200 225 250 300 350 400 450 500 600

Summary of Contents for 954771

Page 57: ...57 LJ...

Page 58: ...58 LJ B A C D 7 7 2 7 RZ DW...