11

Dangerous voltages capable of causing death are

sometimes present in this instrument. Before instal-

lation or beginning any troubleshooting procedures, the

power to all equipment must be switched off and isolated.

Units suspected of being faulty must be disconnected and

removed to a properly equipped workshop for testing and

repair. Component replacement and internal adjustments

must be made by a qualified maintenance person only.

To minimize the possibility of fire or shock hazards

do not expose this instrument to rain or excessive

moisture.

Do not use this instrument in areas under hazardous

conditions such as excessive shock, vibration, dirt,

moisture, corrosive gases or oil. The ambient temperature

of the area should not exceed the maximum rating specified

in chapter 6.

2–1 Unpacking

Upon receipt of the shipment, remove the unit from the car-

ton and inspect the unit for any shipping damage.

If there is any damage due to transit, report it and file a

claim with the carrier. Write down the model number, seri-

al number and date code. for future reference when corre-

sponding with our Service Department. The serial number

(SN) and date code (D/C) are labeled on the box and the

housing of the unit.

2–2 Mounting

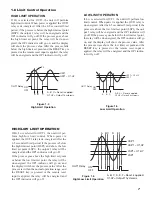

Make the panel cutout according to the dimensions shown

in figure 2.1.

Remove the mounting clamps and screws and insert the

controller into the panel cutout. Reinstall the mounting

clamp and screws. Gently tighten the screws until the front

panel fits snugly in the cutout.

Chapter 2 Installation

53 mm

(2-1/8")

Panel

Panel Cutout

92 mm

(3-5/8")

92 mm

(3-5/8")

Figure 2.1 Mounting Diagram

2–3 Wiring Precautions

• Before wiring, verify the correct model number and

options on the label. Switch off the power while checking.

• Care must be taken to ensure that the maximum voltage rating

specified on the label is not exceeded.

• It is recommended that the power for these units be protected

by fuses or circuit breakers rated at the minimum value pos-

sible.

• All units should be installed inside a suitably grounded metal

enclosure to prevent live parts from being accessible to

human hands and metal tools.

• All wiring must conform to appropriate standards of good

practice and local codes and regulations. Wiring must be

suitable for the voltage, current, and temperature rating of

the system.

• Beware not to over-tighten the terminal screws. The torque

should not exceed 1N-m (8.9 lb-in or 10 KgF-cm)

• Unused control terminals should not be used as jumper

points as they may be internally connected, causing damage

to the unit.

• Verify that the ratings of the output devices and the inputs as

specified in chapter 6 are not exceeded.

• Except the thermocouple wiring, all wiring should use

stranded copper conductor with maximum gauge of 18

AWG.

Figure 2.2

Lead Termination

Figure 2.3

Rear Termination Connection Diagram

Notes: 50°C max. air ambient

Use copper conductors (except on T/C input)

ASTM thermocouples (USA), the red colored lead

is always negative

.

Summary of Contents for TEC-410

Page 26: ...24 ...