12

2–4 Power Wiring

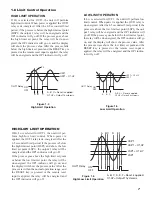

The controller is designed to operate at

11–26VAC/VDC to 90–250VAC. Check that the

installation voltage corresponds to the power rating

indicated on the product label before connecting

power to the controller. Near the controller a fuse

and a switch rated at 2A/250VAC should be

equipped as shown in Figure 2-4.

This equipment is designed for installation in an

enclosure which provides adequate protection against

electric shock. The enclosure must be connected to

earth ground.

Local requirements regarding electrical installation should

be rigidly observed. Consideration should be given to pre-

vent unauthorized personnel from accessing the power ter-

minals.

2–5 Sensor Installation Guidelines

Proper sensor installation can eliminate many problems in a

control system. The probe should be placed so that it can

detect any temperature change with minimal thermal lag. In

a process that requires fairly constant heat output, the probe

should be placed close to the heater. In a process where the

heat demand is variable, the probe should be close to the

work area. Some experimentation with probe location is

often required to find the optimum position.

In a liquid process, the addition of agitation will help to

eliminate thermal lag. Since the thermocouple is basically a

point measuring device, placing more than one thermocou-

ple in parallel will provide an average temperature readout

and produce better results in most air heated processes.

Proper sensor type is also a very important factor in obtain-

ing precise measurements. The sensor must have the correct

temperature range to meet the process requirements. In spe-

cial processes, the sensor might have requirements such as

leak-proof, anti-vibration, antiseptic, etc.

Standard sensor limits of error are ±4°F (±2°C) or 0.75% of

the sensed temperature (half that for special limits of error)

plus drift caused by improper protection or an over-temper-

ature occurrence. This error is far greater than controller

error and cannot be corrected on the sensor except by prop-

er selection and replacement.

90 250 VAC or

11 26 VAC / VDC

~

~

Fu

s

e

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Figure 2.4

Power

S

upply Connections

2–6 Thermocouple Input Wiring

Thermocouple input connections are shown in figure 2-5.

The correct type of thermocouple extension lead-wire or

compensating cable must be used for the entire distance

between the unit and the thermocouple, ensuring that the

correct polarity is observed throughout. Junction/terminal

blocks or splices in the cable run should be avoided, if pos-

sible.

If the length of the thermocouple plus the extension wire is

too long, it may affect the temperature measurement. A 400

ohms K type or a 500 ohms J type thermocouple lead resist-

ance will produce approximately 1°C temperature error.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

1

2

2

3

3

4

4

ON

O

N

+

Dip

S

witch

—

Figure 2.5

Thermocouple Input Wiring

Summary of Contents for TEC-410

Page 26: ...24 ...