- 3 -

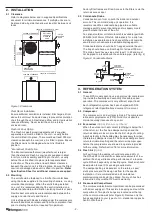

Figure 3. Pressurisation bung locations

4. CONTROLS

4.1 Electrical Requirements

Electrical work must be done by a qualified electrician.

DANGER! LIVE ELECTRICAL CONNECTIONS. DISCONNECT MAINS

POWER BEFORE WORKING ON UNIT. ONLY QUALIFIED PERSONS

WHO ARE COMPETENTLY TRAINED SHOULD PERFORM SERVICE AND

MAINTENANCE TASKS.

The outdoor unit must be wired directly from a distribution

board by means of a circuit breaker and a mains isolator

provided – preferably close to the unit.

A 24 hour power supply to the compressor crank case

heaters is required, otherwise the warranty is void.

4.2 Control options

OPA Econex units can be controlled using any of the

following options:

• TZT-100 wall thermostat

• SAT-3 wall thermostat

• 24V AC and 0-10V signals from an external controller or

thermostat

• Remote on/off switch and/or time clock

• Modbus RTU serial communications over RS485

connection

• BACnet-IP serial communications over Ethernet

connection (with optional gateway module)

Standard reverse cycle units are suitable for use with

thermostats and controls with manual heating/cooling

selection or automatic change-over.

A unit wiring diagram is supplied alongside the electrical

board and in the Specifications document.

4.3 TZT-100 or SAT-3 wall thermostat

To connect the thermostat to the unit it is recommended

to use shielded twisted pair type cable, suitable for RS485

communications. Signals A and B should form one twisted

pair.

Note: The cable shield should connect to terminal ‘0V’ on

the UC8 controller only. Do not connect at both ends.

Connect the thermostat as follows:

TZT-100 Connection:

TB5

B1

TB6

A1

TB7

0V

TB8

12V

TB9

B

A

24C

24

W6

PCLP1

TZT-100

OPA

TB5

B1

TB6

A1

TB7

0V

TB8

12V

TB9

B

A

GRND

12V

W6

PCLP1

SAT-3

OPA

Control

- shielded

twin twisted pair

4 core

(201-000-399)

Control

- shielded

twin twisted pair

4 core

(201-000-399)

SAT-3 Connection:

TB5

B1

TB6

A1

TB7

0V

TB8

12V

TB9

B

A

24C

24

W6

PCLP1

TZT-100

OPA

TB5

B1

TB6

A1

TB7

0V

TB8

12V

TB9

B

A

GRND

12V

W6

PCLP1

SAT-3

OPA

Control

- shielded

twin twisted pair

4 core

(201-000-399)

Control

- shielded

twin twisted pair

4 core

(201-000-399)

Note: Capacity Staging. A TZT-100 or SAT-3 must be

configured for single-stage operation, the default setting.

TZT-100 has its own DIP switches that must be set as

follows:

DIP switch 2

ON

Equipment type = Heat Pump

DIP switch 3

OFF Equipment stages = One

DIP switch 4

ON

Reverse cycle valve on = Heating

SAT-3: Refer SAT-3 Installation Set-up Guide page 3.

4.4 Communications format for TZT-100 and SAT-3

Communications format must be set as per recommended

Modbus RTU:

• Baud rate (bd or br) 19200

• Data bits

8

• Parity

Even

• Stop bits (Pa)

1

• TZT-100 address (Ad) 7

• SAT-3 address (Ad) 8

TZT-100:

The procedure to check and adjust these settings is:

1. Press and hold the O/RIDE button until the display

shows the PIN

2. Use the UP & DOWN buttons to select PIN code 88:21,

then press O/RIDE in installer mode.

3. Use the O/RIDE and PROG buttons to cycle through the

various installer settings.

If necessary, refer TZT-100 User Manual for more detail.

SAT-3:

The procedure to check and adjust these settings is:

1. Press and hold the MODE and 6 button until the display

shows the ‘i’ symbol.

2. Use the UP & DOWN buttons to cycle through the

various installer settings.

3. Press MODE button to save any new setting.

If necessary, refer SAT-3 Installation Set-up Guide for more

detail.

4.5 Remote on/off

The UC8 has an input for a remote on/off function on

terminal ‘On’, signal return is terminal ‘0V’. When used the

remote on/off terminals should connect to a voltage-free

relay contact. When not used the remote on/off terminals

should be shorted (‘bridged’).

4.6 Capacity control

OPA Econex units offer the following capacity control

options:

• Automatic control when the unit connects to the TZT-100

or SAT-3 wall thermostat.

• 0-10V compressor control signal

• 0-10V indoor fan control signal.

• Control by a building management system via Modbus

RTU or BACnet-IP serial communications.

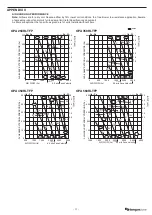

Drawn:

Title:

Drawing No:

23/02/2022

pchandrasekaran

A

Rev:

Date:

©temperzone Ltd 2021

OPA 560 RLTFPQ-CZ (01, 10, 23, 32)

OPA 560 RLTFPQ-CZ Combined Variants

876-056-700

Est Weight:

0 kg

Sheet 1 of 1

*876-056-700/A*

3rd ANGLE PROJECTION

Do not scale drawing

Interpret drawing as per GD&T standard: ISO 2768-1

Unless specified all dimensions are in millimeters

Mat:

Fin:

PROPRIETARY & CONFIDENTIAL

The information contained in

this drawing is the sole

proprietary of temperzone limited.

Unauthorised copying,

possession, discussion, publication

& distribution prohibited

TOLERANCES UNLESS STATED

LINEAR: ANGULAR:

0 = ±0.5 0 = ±1°

0.0 = ±0.1 0.0 = ±0.5°

0.00 = ±0.05 0.00 = ±0.1°

Standard hand unit

Opposite hand unit