11

Temposonics

®

GB-Series SSI

Operation Manual

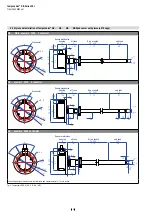

,QVWDOODWLRQRI*%ZLWKWKUHDGHGĠDQJHŊ0ʼn Ŋ7ʼn

)L[WKHVHQVRUURGYLDWKUHDGHGĠDQJH0ūJRUŧ81)$

Base unit

xample

6 connector

34.5

(1.36)

Ø 6.81

(Ø 0.27)

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

8QOHVVRWKHUZLVHVWDWHGDSSO\WRWKHJHQHUDOWROHUDQFHVDFFRUGLQJWR',1,62P

)LJ7HPSRVRQLFV

®

GB-B

Fig. 9:

0RXQWLQJH[DPSOHRIWKUHDGHGĠDQJHŊ0ʼn Ŋ7ʼn

NOTICE

7KH*%%LVRQO\IRUUHSODFHPHQW

8VHWKH*%%VHQVRUZLWKDURGRIWKH*%0RU*%7VHQVRURQO\

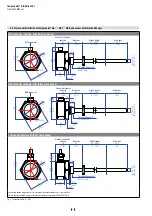

Installation of a rod-style sensor in a

hydraulic

cylinder

The rod-style version has been developed for direct stroke

measurement in a

hydraulic

cylinder. Mount the sensor via

WKUHDGHGĠDQJH

Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

WKURXJKWKHURGZDOOŋLQGHSHQGHQWRIWKHK\GUDXOLFĠXLG

The pressure resistant sensor rod is installed into a bore in the

piston rod.

The base unit is mounted by means of only three screws. It is the

only part that needs to be replaced if servicing is required, i.e. the

hydraulic circuit remains closed. For more information see chapter

Ń5HSODFHPHQWRIEDVHXQLWńRQSDJH

Fig. 10:

6HQVRULQF\OLQGHU

ydraulics sealing

7KHUHDUHWZRZD\VIRUVHDOLQJWKHĠDQJHFRQWDFWVXUIDFH)LJ

1.

$VHDOLQJE\XVLQJDQ2ULQJHJūPPūLQ

in a cylinder end cap groove.

2. A sealing via an O-ring in the undercut.

)RUWKUHDGHGĠDQJHŧ81)$*%7

2ULQJūPPūLQSDUWQR

)RUWKUHDGHGĠDQJH0ūJ*%7

2ULQJūPPūLQSDUWQR

,QWKHFDVHRIWKUHDGHGĠDQJH0ūJDVFUHZKROHEDVHGRQ

,62)LJPXVWEHSURYLGHG6HH,62IRUIXUWKHU

information.

Fig. 11:

3RVVLELOLWLHVRIVHDOLQJ

NOTICE

The orientation of the sensor electronics housing respectively of

WKHHOHFWULFDOFRQQHFWLRQRIVHQVRUPRGHOV*%0DQG*%7FDQEH

changed after mounting. For more information see chapter “4.5

Change orientation of sensor electronics housing” on page 14.

MTS recommendation

R

R

R

Fastening torque

50 Nm

In the event of servicing, the sensor rod

with flange remains in the cylinder

Position magnet

Base unit

The sensor electronics housing

with sensing element can be replaced

Sealing via O-ring

in the flange undercut

Sealing via O-ring

in cylinder end cap groove