F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

54

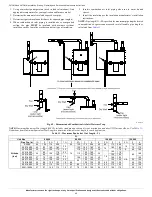

3. Jumper R to W/W1 and W2. Run furnace for 3 minutes in

maximum heat operation.

4. Measure time (in sec) for gas meter to complete one revolution and

note reading. The 2 or 5 cubic feet dial provides a more accurate

measurement of gas flow.

5. Refer to

for cubic ft. of gas per hr. Multiply gas rate cu

ft./hr by heating value (BTUh/cu ft.) to obtain input rate.

6. If clocked rate does not match required input from Step 5, increase

manifold pressure to increase input or decrease manifold pressure

to decrease input. Repeat steps 3 through 5 until correct maximum

heat input is achieved. See

NOTE:

Setup switches SW1-2 must be ON and SW4-2 must be OFF.

This keeps furnace locked in minimum heat operation when R to W/W1

is energized. Repeat items 3 through 6 for minimum heat operation until

minimum heat input is achieved.

7. Remove jumpers across thermostat connections to terminate the

call for heat. Wait until the blower off delay is completed then reset

115-v power to furnace.

8. Restore furnace to normal operating condition.

A11461

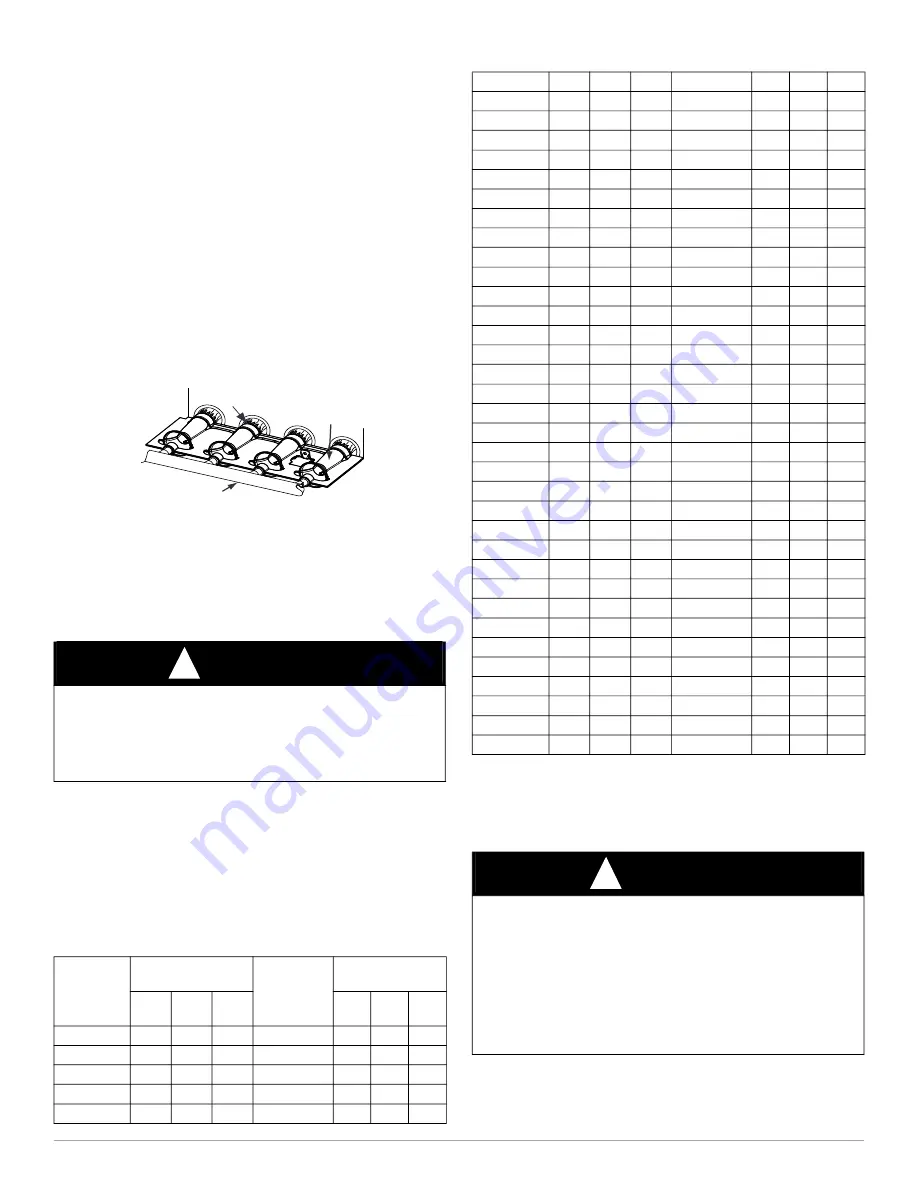

Fig. 63 – Burner Flame

9. Remove jumpers across thermostat connections to terminate the

call for heat. Wait until the blower off delay is completed.

10. Disconnect 115 VAC power to furnace.

11. Turn gas valve ON/OFF switch to OFF.

12. Remove water column manometer or similar device from manifold

pressure tap.

13. Tighten set screw on manifold tower pressure tap with 3/32-in hex

wrench, or if 1/8-in. NPT plug was removed, apply pipe dope

sparingly to end of plug and reinstall in the gas valve.

14. Turn gas valve ON/OFF switch to ON.

15. Move setup SW1-2 on furnace control to position required for

attached thermostat (OFF for single-stage thermostats, ON for

two-stage thermostats).

16. Check for gas leaks and verify furnace operation.

.

Adjust Temperature Rise

NOTE:

Blower door must be installed when taking temperature rise

reading. Leaving blower door off will result in incorrect temperature

measurements,

due to possible changes in duct static pressure and

airflow.

When setup switch SW1-4 is ON, operation will be near the high end of

the rise range for improved comfort.

Furnace must operate within ranges of temperature rise specified on the

furnace rating plate. Determine air temperature rise as follows:

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Manifold pressure tap set screw must be tightened or

⅛

-in. NPT pipe

plug must be installed to prevent gas leaks.

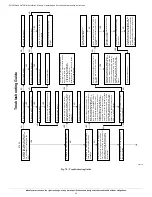

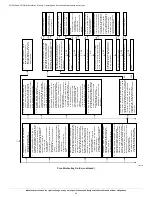

Table 17 – Gas Rate (CU ft./hr)

SECONDS

FOR 1 REV

SIZE OF TEST DIAL

SECONDS

FOR 1 REV

SIZE OF TEST

DIAL

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

10

360

720 1800

50

72

144 360

11

327

655 1636

51

71

141 355

12

300

600 1500

52

69

138 346

13

277

555 1385

53

68

136 340

14

257

514 1286

54

67

133 333

Burner Flame

Burner

Manifold

15

240

480 1200

55

65

131 327

16

225

450 1125

56

64

129 321

17

212

424 1059

57

63

126 316

18

200

400 1000

58

62

124 310

19

189

379

947

59

61

122 305

20

180

360

900

60

60

120 300

21

171

343

857

62

58

116 290

22

164

327

818

64

56

112 281

23

157

313

783

66

54

109 273

24

150

300

750

68

53

106 265

25

144

288

720

70

51

103 257

26

138

277

692

72

50

100 250

27

133

267

667

74

48

97

243

28

129

257

643

76

47

95

237

29

124

248

621

78

46

92

231

30

120

240

600

80

45

90

225

31

116

232

581

82

44

88

220

32

113

225

563

84

43

86

214

33

109

218

545

86

42

84

209

34

106

212

529

88

41

82

205

35

103

206

514

90

40

80

200

36

100

200

500

92

39

78

196

37

97

195

486

94

38

76

192

38

95

189

474

96

38

75

188

39

92

185

462

98

37

74

184

40

90

180

450

100

36

72

180

41

88

176

439

102

35

71

178

42

86

172

429

104

35

69

173

43

84

167

419

106

34

68

170

44

82

164

409

108

33

67

167

45

80

160

400

110

33

65

164

46

78

157

391

112

32

64

161

47

76

153

383

116

31

62

155

48

75

150

375

120

30

60

150

49

73

147

367

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in:

S

Overheating the heat exchangers or condensing flue gases in heat

exchanger areas not designed for condensate.

S

Shortened furnace life

S

Component damage.

Temperature rise must be within limits specified on furnace rating plate.

Recommended operation is at midpoint of rise range or slightly above.

Table 17 – Gas Rate (CU ft./hr) (Continued)