F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

29

A11157

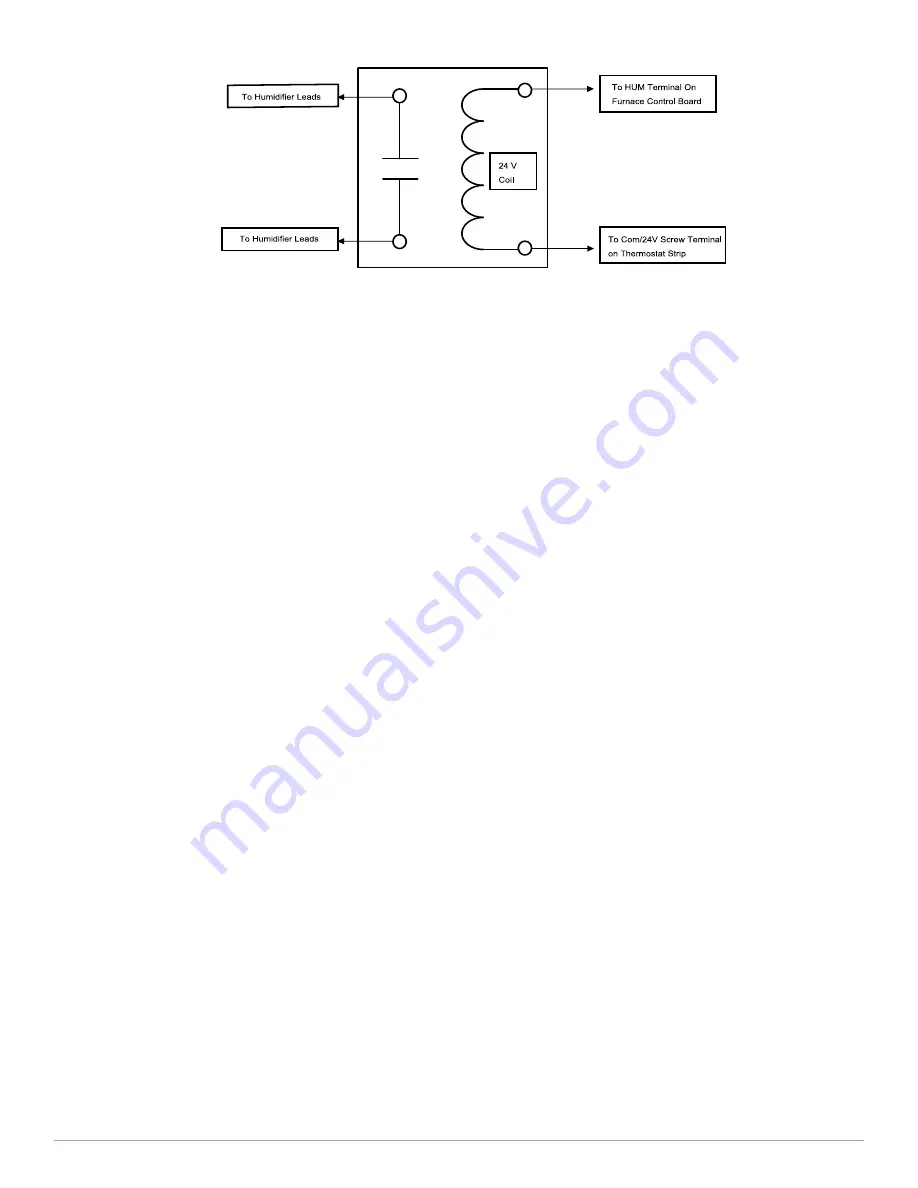

Fig. 37 – Field-supplied Isolation Relay for Humidifiers with Internal Power Supply

Accessories

.)

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used) using 1/4-in.

female quick connect terminals to the two male 1/4-in.

quick-connect terminals on the control board marked EAC-1 and

EAC-2. The terminals are rated for 115VAC, 1.0 amps maximum

and are energized during blower motor operation.

2. Humidifier (HUM)

The HUM terminal is a 24 VAC output, energized when the blower

is operating during a call for heat.

Connect an accessory 24 VAC, 0.5 amp. maximum humidifier (if

used) to the

¼

-in. male quick-connect HUM terminal and

COM-24V screw terminal on the control board thermostat strip.

NOTE:

If the humidifier has its own 24 VAC power supply, an isolation

relay may be required. Connect the 24 VAC coil of the isolation relay to

the HUM and COM/24V screw terminal on the control board thermostat

strip, see

3. Communication Connector (communication connection)

This connection is used when the furnace is controlled by an

optional communicating User Interface instead of a standard

thermostat. The communication plug is supplied with the User

Interface. Refer to the instructions supplied with the User Interface

.

4. Outside Air Thermistor (OAT)

The OAT connection is used in conjunction with communicating

User Interface. It is not required when the furnace is controlled by a

standard type thermostat. Refer to the instructions supplied with the

User Interface for complete details.

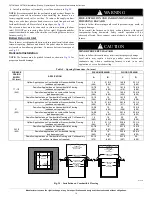

Alternate Power Supplies

This furnace is designed to operate on utility generated power which has

a smooth sinusoidal waveform. If the furnace is to be operated on a

generator or other alternate power supply, the alternate power supply

must produce a smooth sinusoidal waveform for compatibility with the

furnace electronics. The alternate power supply must generate the same

voltage, phase, and frequency (Hz) as shown in

or the furnace

rating plate.

Power from an alternate power supply that

is non-sinusoidal may

damage the furnace electronics

or cause erratic operation.

Contact the alternate power supply manufacturer for specifications and

details.

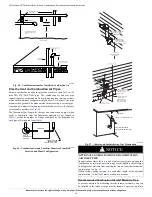

VENTING

NOTE:

Planning for the venting system should be done in conjunction

with planning for the ductwork, drainage, and furnace accessories, such

as air cleaners and humidifiers. Begin assembling the venting system

AFTER

the furnace is set in place in the required orientation.

Venting for this furnace shall follow all Local codes for Category IV

venting systems. This furnace is CSA approved for venting with

PVC/ABS DWV venting systems. This furnace is also CSA approved

for venting with M&G DuraVent

R

PolyPro

R

or Centrotherm Innoflue

R

polypropylene venting systems - straight pipe and fittings (elbows,

reducers, increasers, connectors, adapters) only.

NOTE:

THESE INSTRUCTIONS

DO NOT

CONTAIN DETAILED

INSTALLATION INSTRUCTIONS FOR POLYPROPYLENE

VENTING SYSTEMS. Refer to the polypropylene venting system

manufacturer’s installation instructions for the polypropylene venting

system installation.

NOTE:

When using polypropylene venting systems, all venting

materials used, including the vent terminations, must be from the same

manufacturer.

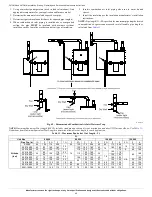

Special Venting Requirements for Installations in

Canada

Installation in Canada must conform to the requirements of CSA B149

code. Vent systems

must

be composed of pipe, fittings, cements, and

primers listed to ULC S636. The special vent fittings, accessory

concentric vent termination kits and accessory external drain trap

available from the furnace manufacturer have been certified to ULC

S636 for use with those Royal Pipe and IPEX PVC vent components

which have been certified to this standard. In Canada, the primer and

cement must be of the same manufacturer as the vent system – GVS-65

Primer (Purple) for Royal Pipe or IPEX System 636, PVC/CPVC

Primer, Purple Violet for Flue Gas Venting and GVS-65 PVC Solvent

Cement for Royal Pipe or IPEX System 636

(1)

t, PVC Cement for Flue

Gas Venting, rated Class IIA, 65 deg C. must be used with this venting

system - do not mix primers and cements from one manufacturer with a

vent system from a different manufacturer. Follow the manufacturer’s

instructions in the use of primer and cement and never use primer or

cement beyond its expiration date.

The safe operation, as defined by ULC S636, of the vent system is based

on following these installation instructions, the vent system

manufacturer’s installation instructions, and proper use of primer and

cement. All fire stop and roof flashing used with this system must be UL

listed material. Acceptability under Canadian standard CAN/CSA B149

is dependent upon full compliance with all installation instructions.

Under this standard, it is recommended that the vent system be checked

once a year by qualified service personnel.

The authority having jurisdiction (gas inspection authority, municipal

building department, fire department, etc.) should be consulted before

installation to determine the need to obtain a permit.

*IPEX System 636™ is a trademark of IPEX Inc.

Consignes spéciales pour l’installation de ventilation au Canada

L’installation faite au Canada doit se conformer aux exigences du code

CSA B149. Ce systême de ventillation

doit

se composer de tuyaux,

raccords, ciments et apprêts conformes au ULC S636. La tuyauterie de