INSTALLATION INSTRUCTIONS

Gas Furnace: (F/G)MAC

440 01 4201 01

17

Specifications subject to change without notice.

12. If the “Z” pipe does not extend through the casing, slide a

piece of field supplied CPVC through the grommet in the

casing, otherwise, go to Step 17.

13. Cement a 1/2-in. CPVC coupling to the end of the CPVC

pipe.

14. Apply cement to the end of the “Z” pipe connected to the

condensate trap.

15. Connect the field-supplied CPVC pipe to the CPVC pipe

connected to the condensate trap.

16. Cut off excess CPVC pipe outside the casing.

17. Connect additional 1/2-in. CPVC piping to a condensate

pump approved for use with acidic furnace condensate

or to a code-approved drain.

18. When a condensate pump is not used, slope the pipe

away from the furnace to allow for proper drainage.

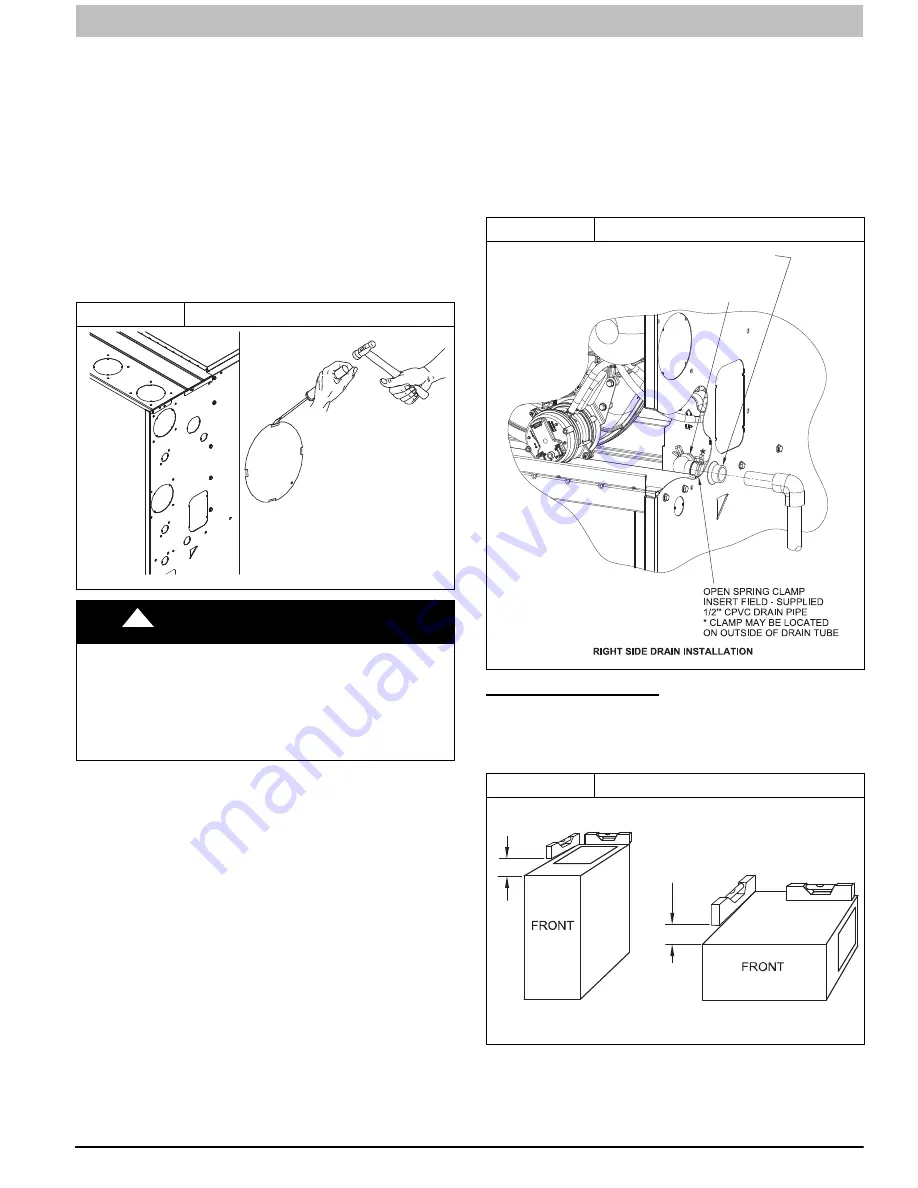

Figure 15

Knockout Removal

A11305

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts, and servicing

furnaces.

Horizontal Orientation

1. In the Horizontal orientation, a field supplied accessory

drain trap grommet is required to seal the gap between

the casing and the condensate trap for direct vent

applications only. The condensate trap outlet extends 2

inches (51 mm) below the furnace casing. To allow for

servicing the trap, the condensate drain tube in the loose

parts bag can be modified to make a coupler to allow for

future service of the condensate trap and drain line.

2. Remove the knock-out for the condensate trap in the

side of the casing.

3. Install the drain trap grommet in the casing (for direct

vent applications). If necessary, remove the trap, install

the grommet and re-install the trap.

4. Remove the pre-formed drain tube, the offset 1/2-in.

CPVC pipe and two spring clamps from the loose parts

bag.

5. Remove the formed grommet on the tube to create an

elbow or straight connector. (See

Figure 16

)

6. Connect the cut tube to the outlet of the condensate trap

with 1 spring clamp.

7. Slide the other spring clamp down the plain end of the

drain tube.

8. Connect additional 1/2

−

in. CPVC piping to the open end

of the tube.

9. Slide the spring clamp down over the 1/2

−

in. CPVC pipe.

10. Connect additional 1/2

−

in. CPVC piping to a condensate

pump approved for use with acidic furnace condensate

or to a code

−

approved drain.

11. When a condensate pump is not used, slope the pipe

away from the furnace to allow for proper drainage.

Figure 16

Formed Tube Grommet

INSTALL CLAMPS ON DRAIN TUBE

ATTACH DRAIN TUBE TO CONDENSATE

DRAIN TRAP

PULL DRAIN STUB

THROUGH CASING

A11342

INSTALLATION

UPFLOW INSTALLATION

NOTE

: The furnace must be pitched forward as shown in

Figure 17

for proper condensate drainage.

Figure 17

Furnace Pitch Requirements

LEVEL 0-IN. (0 MM) TO

1/2-IN. (13 MM) MAX

UPFLOW OR

DOWNFLOW

HORIZONTAL

MIN 1/4-IN. (6 MM) TO

1/2-IN. (13 MM) MAX

A11237

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible