CF Series Portable Chiller : Air & Water-Cooled : 5 - 40 Tons

Page: 19

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

2.

Electrical power supply requirements for standard units

are identified on the equipment data tag. Determine

that the plant’s voltage supply is the same as the unit’s

voltage requirements, taking into account the SSCR

Rating.

3.

A customer supplied, four conductor cable is

required for connection to a customer supplied fused

disconnecting means. The fused disconnecting means

shall be sized and installed according to the unit’s

power supply requirements and local electrical codes.

(Some custom units may include a fused or non-fused

disconnect switch.)

4.

Connect the four conductor power cable to the power

entry terminal block on the unit’s electrical panel. Then

connect the power cable to the fused disconnect switch.

There is no power entry hole into the electrical cabinet. This allows the matching

of the entry hole size and location to the customer supplied fittings.

5.

A unit specific electrical drawing is shipped with the unit.

6.

Voltage supplies must be /- 10% of the name plate voltage and must be

within 2% from leg to leg. Extreme voltage imbalance or using the wrong voltage

can damage your chiller and cause premature unit failure as well as a safety risk.

7.

A proper ground is required for the unit.

B.

CONTROL CIRCUIT WIRING

1.

The unit’s supplied control circuit is 110 volt, 1 phase, 60 cycle.

2.

The control circuit is supplied by the factory installed transformer. A control circuit

fuse is provided.

C.

GENERAL

1.

Make certain all ground connections to the unit are properly affixed.

2.

Make certain power conductor, disconnecting means, and fusing are properly

sized according to the unit’s power supply requirements.

3.

Follow all local and national codes.

4.

Make certain that all owner and factory wire connections are tight before applying

power to the unit.

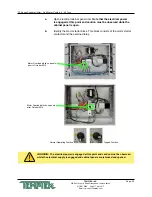

Typical data tag.

WARNING: Check that all electrical connections are tight before starting.

Disconnect power before servicing. Follow all facility lock-out tag-out procedures.

Summary of Contents for CF Series

Page 2: ......

Page 6: ...Page 6 THIS PAGE INTENTIONALLY BLANK ...

Page 22: ...Page 22 THIS PAGE INTENTIONALLY BLANK ...