CF Series Portable Chiller : Air & Water-Cooled : 5 - 40 Tons

Page: 25

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

3.

WATER QUALITY CONTROL. Lack of, as well as, improper water treatment can

damage the chilling unit. The services of competent water treatment specialist

should be obtained and their recommendations followed. It is the equipment

owner’s responsibility to prevent damage from foreign material or inadequate

water treatment. See water treatment section in

section 1.6 of this manual for more information.

4.

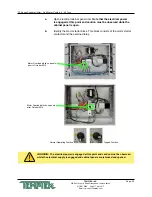

FOR AUTOMATIC FILL: Always install a manual

shut off valve on the make-up water supply on

the outside of the unit. When electrical power is

applied to the unit but the On/Off Selector is in

the ‘off’ position open the owner supplied shut off

valve. The level switch will activate the make-up

solenoid which will open and the water supply will

fill the reservoir tank. Do not use automatic fill

when operating at temperature below 48°F.

5.

MANUAL FILL: Disconnect and lock out

the electrical power supply and remove

all necessary cover panels to access the

reservoir. Add fluid directly to the reservoir.

When the pump is first started, as process

lines are filled and air is purged, additional

fluid may be required to restore the reservoir to

the correct level. Verify reservoir level via the

coolant sight glass.

6.

Do not use deionized water in this unit unless

your unit was specifically designed for use with

deionized water. Consult factory if not certain.

B.

PROPER ROTATION (PHASING) OF SCROLL COMPRESSORS & PUMPS & FANS

1.

Correct compressor, fan (on air-cooled units) and pump rotation is critical for unit

performance and to avoid severe damage to the compressor.

2.

All portable chiller compressors and pumps will be set to rotate in the same

direction during the testing process at the factory except for units with outdoor

remote condensers. The rotation of compressors and pumps on units with remote

condensers must be checked for correct rotation independently.

3.

After electrical installation the rotation must be checked by observing the pump

motor shaft on the end of the pump and comparing its rotation to the directional

arrow on the motor. If the rotation needs to be changed it should be done at the

main power entry by switching any two power conductors at the terminal block or

customer supplied main power disconnect. Recheck rotation before operating the

units.

Make-up solenoid valve

Typical coolant sight glass

WARNING: The electrical power is engaged at this point and caution must be observed while

the electrical supply is engaged and cabinet panels are removed and opened.

Summary of Contents for CF Series

Page 2: ......

Page 6: ...Page 6 THIS PAGE INTENTIONALLY BLANK ...

Page 22: ...Page 22 THIS PAGE INTENTIONALLY BLANK ...