10

OPERATING GUIDELINES

3. Select your desired quick jump temperature level by pressing the

increase or decrease button.

4. To adjust the second quick jump level, repeatedly press the “SET”

button until a number with a prefix “c” is displayed. This denotes that

we are now configuring the Second quick jump setting.

5. Select your desired quick jump temperature level by pressing the

increase or decrease button.

6. To save the settings, repeatedly press the SET button until the

display shows the word “SAVE”. Press the increase button to save

and exit from the system configuration mode.

7. The two quick jump settings has now been configured and can be

accessed by simultaneously pressing the “INCREASE” and “SET”

button for the first Quick jump level. And simultaneously pressing the

“DECREASE” and “SET” button will access the second quick jump

level.

C. SLEEP FUNCTION

The Soldering Iron is equipped with a vibration sensor. When the

soldering iron has been left unmoved the system would begin the count

down of the sleep timer. The suffix will change to a small letter “d” to

indicate that the system is preparing to enter sleep mode. The display

will show four dashes “- - - - “ to indicate the system has entered sleep

mode. To wake the system, simply lift up the soldering iron or push any

control buttons.

Sleep timer is configurable via the following method:

1. With the unit turned On, press and hold the SET button.

2. Wait for the display to change to “A###”, then repeatedly press the

“SET” button until a number with prefix “d” or “d0FF” is displayed.

This denotes that we are now configuring the sleep timer setting.

3. “d0FF” indicates that the sleep function is currently turned off. To

adjust the timer settings press the increase or decrease button.

Sleep timer is adjustable from 1 to 60 minutes.

7

OPERATING GUIDELINES

REMINDERS:

1. Make sure the equipment is placed on a flat stable surface and

all the heat-generating components placed on their respective

holders or stands.

2. Ensure all function switches are in the OFF position.

3. Ensure all terminal connections are properly secured.

IMPORTANT:

Please refer to the

CONTROL PANEL

GUIDE

page for buttons and display

panel directory.

A. INITIAL PROCEDURES

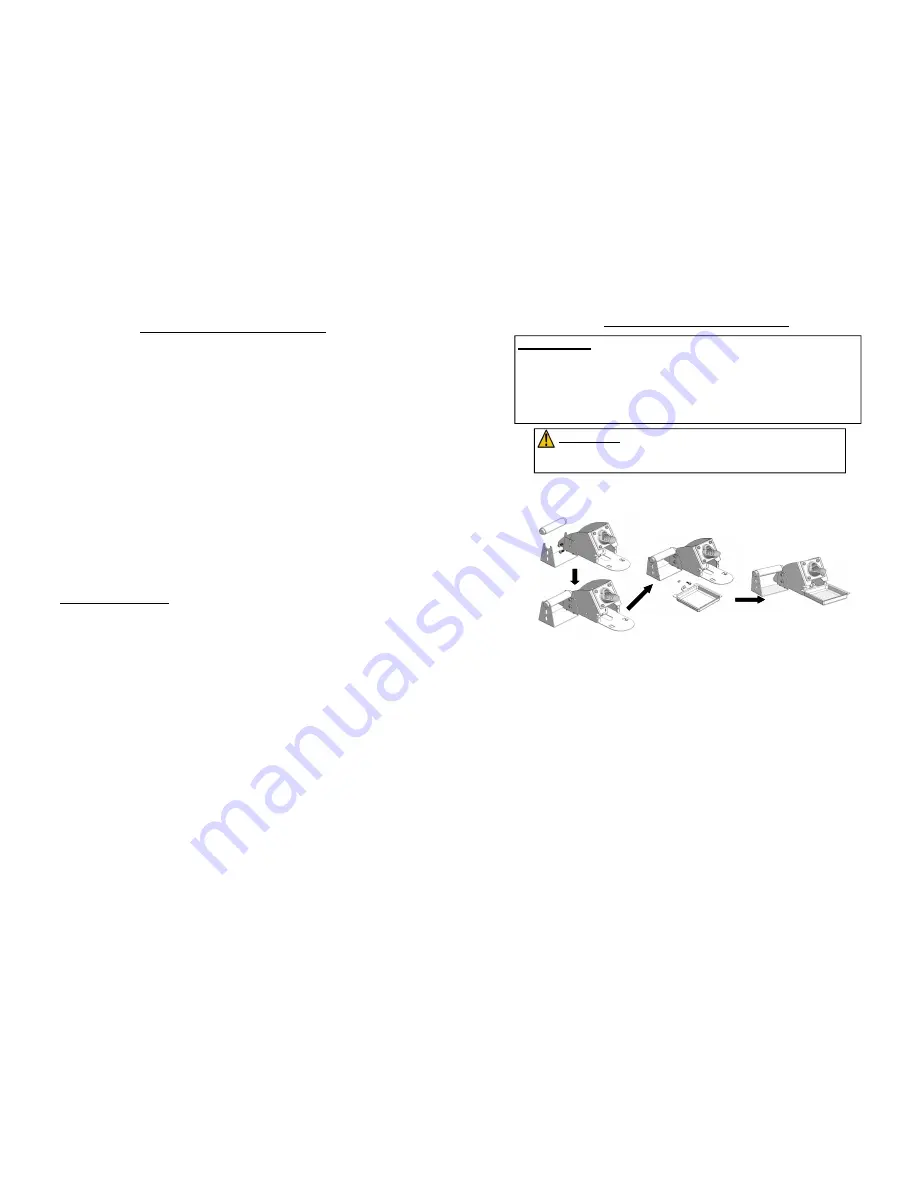

1.Soldering Iron Stand

2. Insert the power cord into the receptacle at the back of the station.

3. Plug the power cord into a grounded wall socket. The station is pro-

tected against electrostatic discharge and must be grounded for full

efficiency.

4. Be sure the power switch is OFF before connecting or disconnecting

the soldering iron cord. Failure to do so may result in damage to the

circuit board.

5. Follow instructions on soldering iron stand assembly guide.

6. Attach the soldering iron to the 5-pin output at the bottom right area

of the station.

7. Place soldering iron to the soldering iron stand as shown .

8. Dampen the sponge with water and squeeze excess water before

using. The tips maybe damaged when used with dry sponge.

9. The unit is now ready for use.

①

③

②