4

●

Programmable power supply with a digital interface

●

Three separately adjustable linear outputs

●

The 192×64 LCD Display can display multiple settings and measurements simultaneously

●

Windows-based interface for user-friendly operation

●

High stability and low drift

●

Over Voltage, Current, and Temperature protection

●

Intelligent fan control adjusts with output power

●

Built-in warning buzzer

●

Accurate user calibration software

●

Space-saving design

●

Fine adjustment knob

●

90 setting memory

●

Parallel, series, and independent operation modes

●

1-second timing resolution.

13

PRODUCT INTRODUCTION

Product Overview

72-8795 Programmable Power Supply is controlled by a Micro Processor

Unit (MPU) that is designed for a communication interface by RS-232 or USB to

computer to enable advanced testing and power delivery by programmable control.

T h e v o l t a g e a n d c u r r e n t a r e c o n t r o l l e d by a 12 b i t D / A C o n v e r t e r

with high resolution and accuracy. Also, the digital inter face provides

a speedy, precise and convenient input of information controlled by intuitive controls.

The adjustment of voltage/current is made by software calibration, eliminating

potential manual fault, that increases the precision of the instrument.

Over Voltage Protection (OVP) and Over Current Protection (OCP) can be set with the

software and utilized by the hardware to achieve precise, instant protection

t o p r e v e n t d a m a g e a n d i n c r e a s e t h e u s e r s ’ s a f e t y .

We warrant this unit to be free from manufacturer material and workmanship defects

for one year from the original date of purchase within North America. If the unit fails

during normal use withing the warranty period, please contact the authorized reseller

of this product for repair or replacement. This warranty does not apply to defects

and failure resulting from customer actions, such as mishandling, misapplication,

overloading power or current, unauthorized repair, or any modification. The reseller

and manufacturer hold the right to deny any warranty claims based on these reasons,

or to fulfill warranty with a similar product at a similar value.

Additional Features

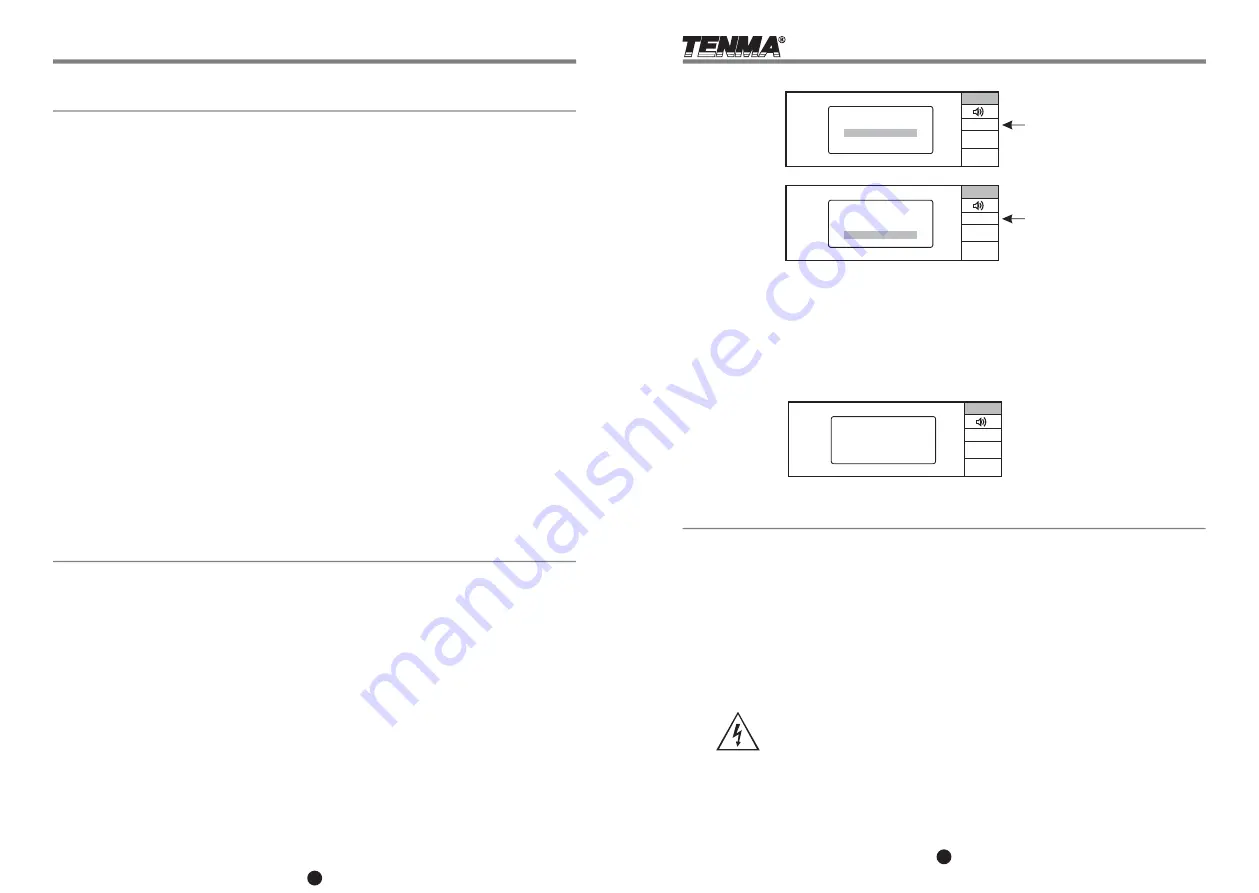

CH1

OFF

CH1

OFF

3 2 . 0 0 V

3 2 . 0 0 V

3 2 . 0 0 V

3 2 . 0 0 V

0 6

. 0 0 V

0 6

. 0 0 V

3 . 0 0 0 A

3 . 0 0 0 A

3 . 0 0 0 A

3 . 0 0 0 A

S h i f t

S h i f t

PARA

SERI

OCP

OFF

OCP

OFF

3 . 0 0 0 A

3 . 0 0 0 A

CH3

OFF

CH3

OFF

CH2

OFF

CH2

OFF

OCP

OFF

OCP

OFF

OUT SET

INDEP OUT

PARA OUT

SERIES OUT

OUT SET

INDEP OUT

PARA OUT

SERIES OUT

8. Communication Setting

Press

[SHIFT][COMM]

to access the interface for the communication setting.

Use the key directions to move the cursor to the corresponding value place. You

can set the power address, communication speed and data bit by using the rotary

knob to change the values. Press

[ENTER]

to store and exit.

CH1

OFF

3 2 . 0 0 V

3 2 . 0 0 V

0 4

. 1 0 V

2 . 0 0 0 A

2 . 0 0 0 A

S h i f t

INDEP

OCP

OFF

2 . 0 0 0 A

CH3

OFF

CH2

OFF

OCP

OFF

INTERFACE

ADDR

:

001

BAUD

:

19200

DATA: 9

GENERAL MAINTENANCE

General Maintenance

To avoid electrical shock, do no perform any service or repair other than those outlined in these

operating instructions. Any additional attempts at servicing or modifying this unit voids all

manufacturer warranty and liability.

1. Fuse Replacement

If the fuse blows, the display will not light and the power supply will not operate.

Replace the fuse with a compatible rated fuse. The unit was originally supplied with a 5 Amp

250V glass type fuse. The fuse compartment is located at the AC plug terminal

WARNING:

Replace fuse only with 250V fuse of the specific type and

rating, and always disconnect power cord before replacing fuse.

Parallel Output Mode

Serial Output Mode