OPERATION

Tennant 1500 (05–99)

9

FIG. 13

9.

When returning for next stroke, push accessory

tool forward over same path with trigger released.

Continue this pull and push method with a 50 to

102 mm (2 to 4 in) overlap of each stroke.

NOTE: For heavily soiled areas, repeat stroke or

change angle of stroke.

10. Empty recovery tank when solution tank runs dry

(See Draining Tanks)

.

ATTENTION: Do not allow foam or water to enter

vacuum standpipe, vacuum motor damage will

result. Ball float shutoff will not keep foam out of

standpipe. Vacuum damage due to foam or water

is not covered by warranty.

DRAINING TANKS

ATTENTION: Raise brush/pickup head when

transporting machine to floor drain.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

DRAINING RECOVERY TANK

Always empty recovery tank when refilling solution

tank. You may refill solution tank while emptying

recovery tank. To drain recovery tank, perform the

following steps:

ATTENTION: If recovery tank is not emptied

between fill–ups, foam or water will enter vacuum

standpipe and damage vacuum motor. Float

shut–off screen will not keep foam out of

standpipe. Vacuum damage due to foam or water

is not covered by warranty.

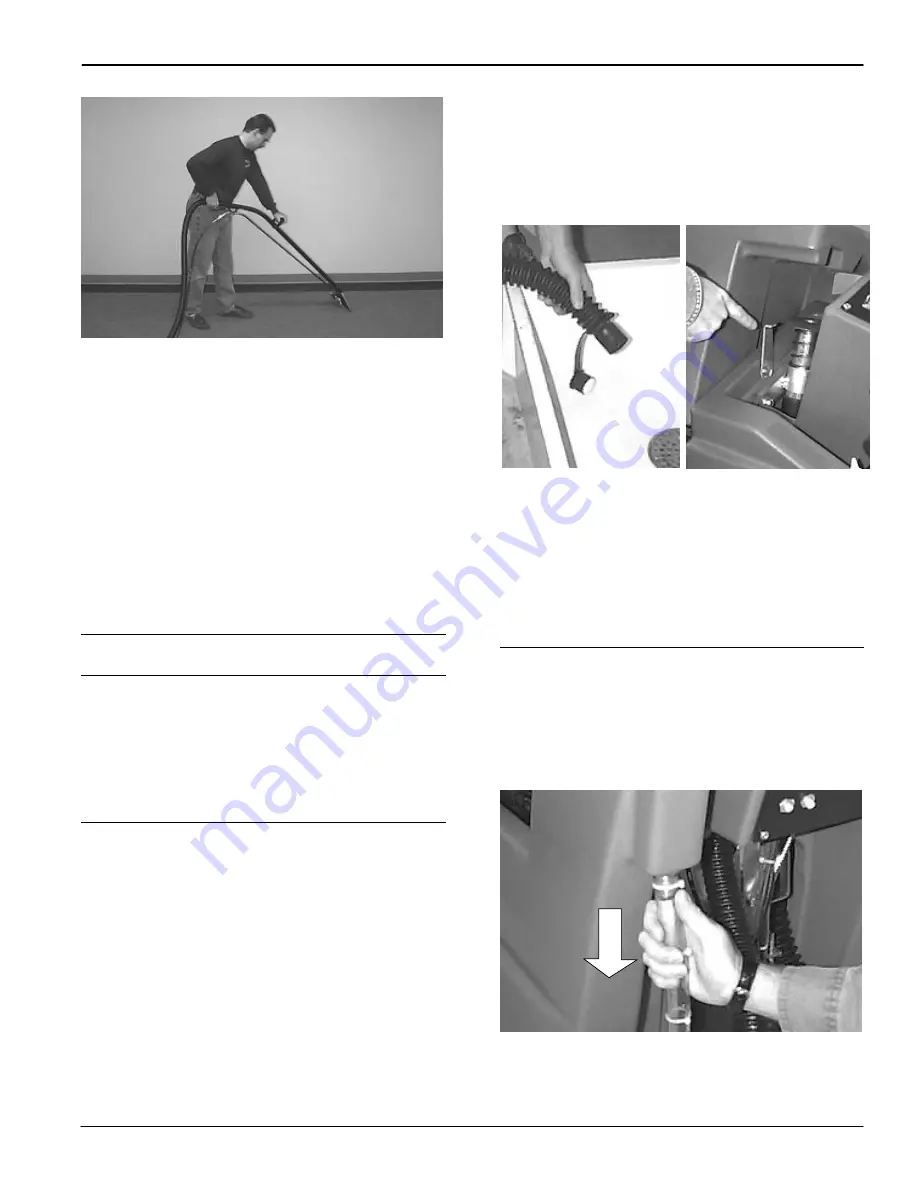

1.

Remove drain hose from holder, position hose

over floor drain and twist off drain hose plug. To

completely drain recovery tank, hinge open tank

and flip up tank support stand to rest tank on

(Figure 14).

NOTE: Use different buckets for filling and emptying

tank. This will prevent possible solution line clogs.

FIG. 14

2.

Rinse out recovery tank after each use. This will

prevent a foul odor and residue buildup in tank.

Unscrew clear lid on recovery tank and rinse out

the tank with hose. Be careful not to spray water

into float shut-off screen.

3.

Replace drain hose plug tightly when tank is

empty.

DRAINING SOLUTION TANK

To drain leftover cleaning solution from solution tank,

follow steps below:

1.

Pull clear hose off hose barb at rear of machine

and drain solution into floor drain or bucket

(Figure 15).

FIG. 15