Summary of Contents for 186

Page 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

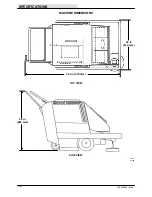

Page 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

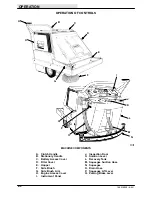

Page 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Page 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Page 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Page 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...