MAINTENANCE

235E MM165 (12--94)

3-6

LUBRICATION

GEARBOX

The gearbox transfers power from the propelling

motor to the rear wheel, and is lubricated with

SAE 90 weight gear lubricant. Check the lubricant

level after every 100 hours of operation. Change

the gear lubricant and the drain and fill/level plug

seals after the first 50 hours of operation and then

after every 1000 hours of operation.

C

B

A

D

05934

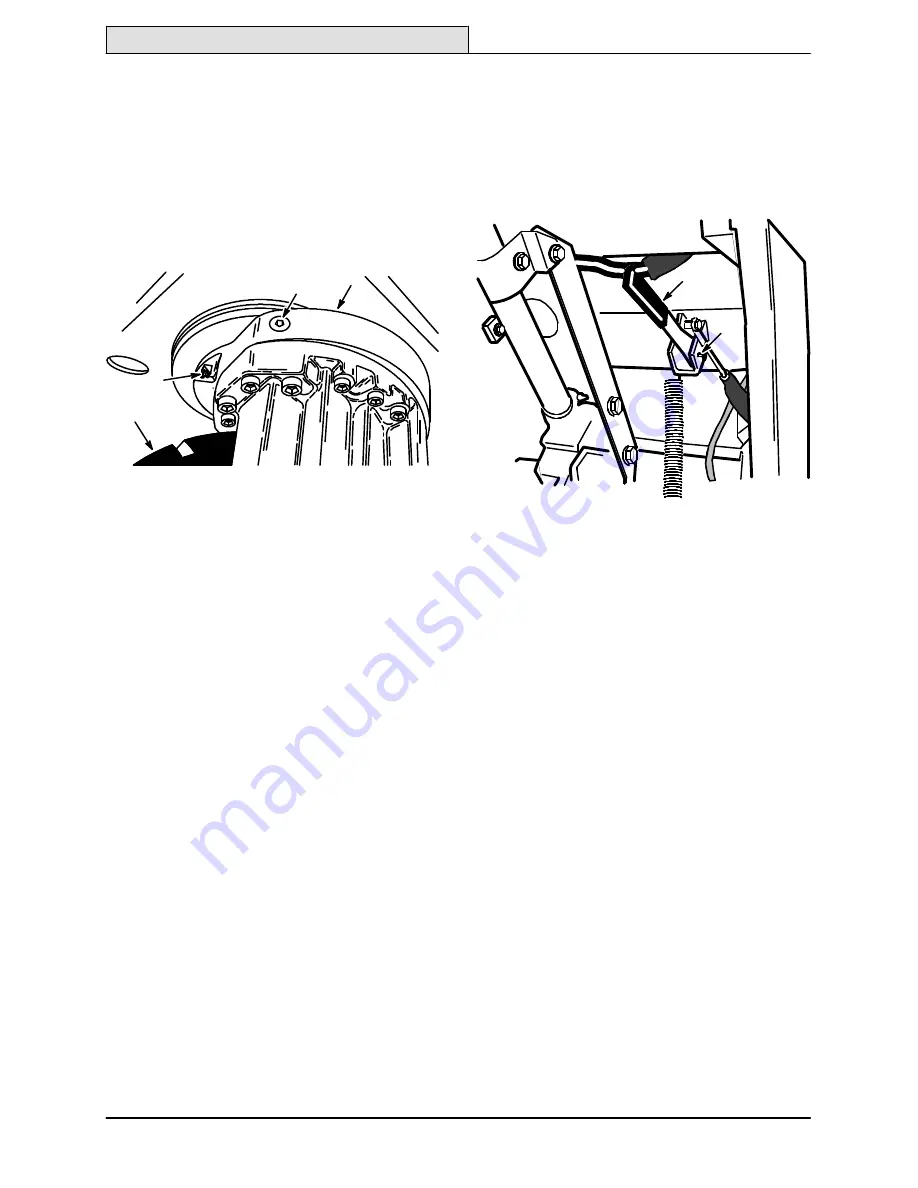

GEARBOX

A. Gearbox

B. Fill/level Plug

C. Support Grease Fitting

D. Rear Wheel

REAR WHEEL SUPPORT BEARING

The rear wheel support bearing allows the

gearbox and rear wheel assembly to rotate freely.

Raise the machine so the rear wheel is off the

ground. Fill one grease fitting with Lubriplate EMB

grease (Tennant Part No. 01433--1) while rotating

the gearbox from stop to stop. Fill the second

grease fitting while rotating the gearbox back to

the original postition. The bearing cavity is full

when grease comes out of the fitting or out of the

top seal. Apply the lubricant after every 200

hours of operation or after steam cleaning the

propelling gearbox area.

FOR SAFETY: When Sevicing Machine, Block

Machine Tires Before Jacking Machine Up.

Jack Machine Up At Designated Locations

Only. Block The Machine Up With Jack

Stands.

SIDE BRUSH LEVER PIVOT

The side brush lever pivot allows the side brush

lever to move freely. Lubricate the pivot with

Lubriplate EMB grease (TENNANT part number

01433--1) after every 200 hours of operation.

A

B

03396

SIDE BRUSH LEVER PIVOT

A. Side Brush Lever

B. Pivot

Summary of Contents for 235E

Page 1: ...235E MM165 Operator Manual ...

Page 6: ...ABOUT THIS MANUAL 235E MM165 3 91 d ...

Page 14: ...SPECIFICATIONS 235E MM165 3 91 1 2 ...

Page 18: ...OPERATION 235E MM165 3 91 2 2 ...

Page 34: ...MAINTENANCE 235E MM165 3 91 3 2 ...

Page 42: ...MAINTENANCE 235E MM165 3 94 3 10 03380 HYDRAULIC SCHEMATIC ...

Page 70: ...MAINTENANCE 235E MM165 3 94 3 38 ...

Page 72: ...APPENDIX 235E MM165 3 91 4 2 ...