MAINTENANCE

235E MM165 (3--93)

3-16

9. Unplug the charger connector from the

battery connector.

10. Reconnect the machine connector to the

battery connector.

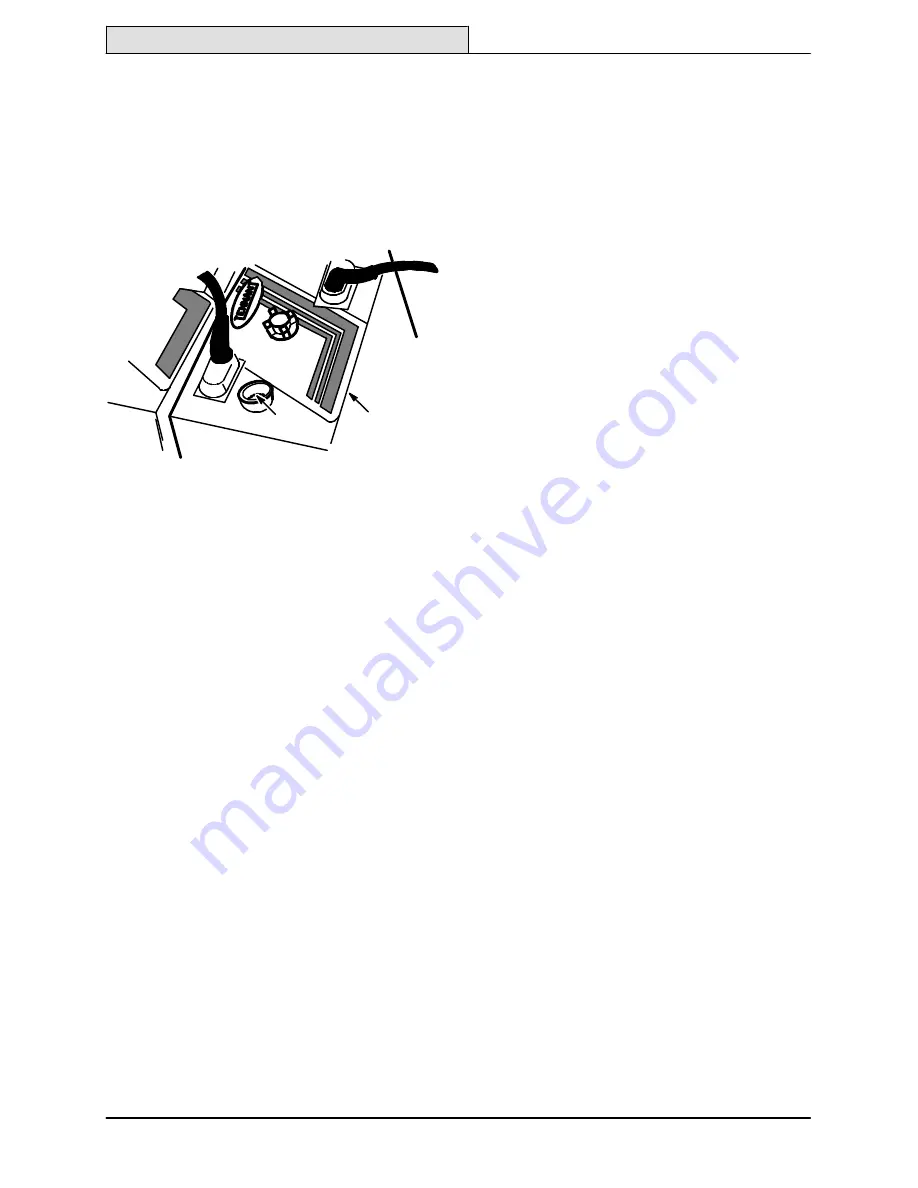

11. Check the electrolyte level of the batteries; it

should be up to the indicator mark.

B

A

00879

CHECKING BATTERY ELECTROLYTE LEVEL

A. Battery

B. Electrolyte Indicator Ring

12. Lower the seat support.

ELECTRIC MOTORS

The electric propelling motor and the accessory

motor are repairable.

Blow out the dust and inspect the motor brushes

in the motors after every 1000 hours of operation.

If the brushes are broken, cracked, chipped, or

have been worn to less than 0.62 in (15 mm) in

length on the short side on the propelling motor,

or 0.38 in (10 mm) on the accessory motor,

replace them. Remember to always replace

brushes in sets.

If the commutator is worn or rough, the motor

armature should be removed and serviced.

Summary of Contents for 235E

Page 1: ...235E MM165 Operator Manual ...

Page 6: ...ABOUT THIS MANUAL 235E MM165 3 91 d ...

Page 14: ...SPECIFICATIONS 235E MM165 3 91 1 2 ...

Page 18: ...OPERATION 235E MM165 3 91 2 2 ...

Page 34: ...MAINTENANCE 235E MM165 3 91 3 2 ...

Page 42: ...MAINTENANCE 235E MM165 3 94 3 10 03380 HYDRAULIC SCHEMATIC ...

Page 70: ...MAINTENANCE 235E MM165 3 94 3 38 ...

Page 72: ...APPENDIX 235E MM165 3 91 4 2 ...