Summary of Contents for 242E

Page 1: ......

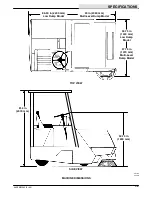

Page 10: ...SPECIFICATIONS 242E MM243 9 89 1 2 ...

Page 14: ...SPECIFICATIONS 242E MM243 9 89 1 6 ...

Page 16: ...OPERATION 242E MM243 5 92 2 2 ...

Page 62: ...MAINTENANCE 242E MM243 5 92 3 22 05805 ELECTRIC SCHEMATIC ...

Page 88: ...MAINTENANCE 242E MM243 5 92 3 48 ...

Page 90: ...APPENDIX 242E MM243 9 89 4 2 ...