MAINTENANCE

3-53

285 MM191 (6---90)

The side brush pattern adjustment on multi-level

dump model machines is made by loosening the two

bolts on the side brush arm, repositioning the side

brush assembly, and retightening the bolts.

A

B

C

00603

MULTI-LEVEL DUMP MODEL SIDE BRUSH

A. Bolt

B. Side Brush Arm

C. Side Brush

TO REPLACE SIDE BRUSH

1. Empty the debris hopper.

2. Raise the hopper, engage the hopper support

bar, and lower the hopper onto the support bar.

WARNING: Falling hopper. Engage hopper

support bar before working under hopper.

3. Stop the engine and set the machine parking

brake.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking brake,

and turn off machine.

4. Place the side brush position lever in the (Side

Brush Up) position.

5. Remove the side brush retaining pin from the

side brush hub and shaft by pulling the pin

keeper off over the end of the pin.

A

B

02485

SIDE BRUSH

A. Side Brush

B. Retaining Pin

6. Slide the side brush off the side brush drive

shaft.

7. Slide the new side brush onto the side brush

drive shaft.

8. Insert the side brush retaining pin through the

side brush hub and shaft.

9. Secure the pin by clipping the pin keeper over

the end of the pin.

10. Adjust the side brush pattern.

11. Disengage the hopper support bar and lower

the hopper.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

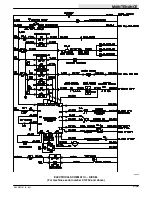

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

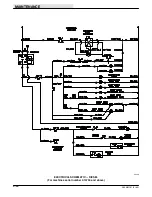

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...