MAINTENANCE

3-59

285 MM191 (6---90)

BRAKES AND TIRES

SERVICE BRAKES

The mechanical service brakes are located on the

front wheels. They are operated by the foot brake

pedal and connecting linkages.

The brake pedal should not travel more than 1 in (25

mm) to fully engage the brakes. Blow the

accumulated dirt from between the brake shoes and

the hub with compressed air through the slots on the

side wheel pockets. Check the brake adjustment

after every 200 hours of operation.

TO ADJUST BRAKE LINKAGE

1. Empty the debris hopper.

2. Park machine on a level surface.

3. Raise the hopper, engage the hopper support

bar, and lower the hopper onto the support bar.

WARNING: Falling hopper. Engage hopper

support bar before working under hopper.

4. Stop the engine.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking brake,

and turn off machine.

5. Block machine tires.

6. Remove the clevis pins from the left and right

side brake clevises.

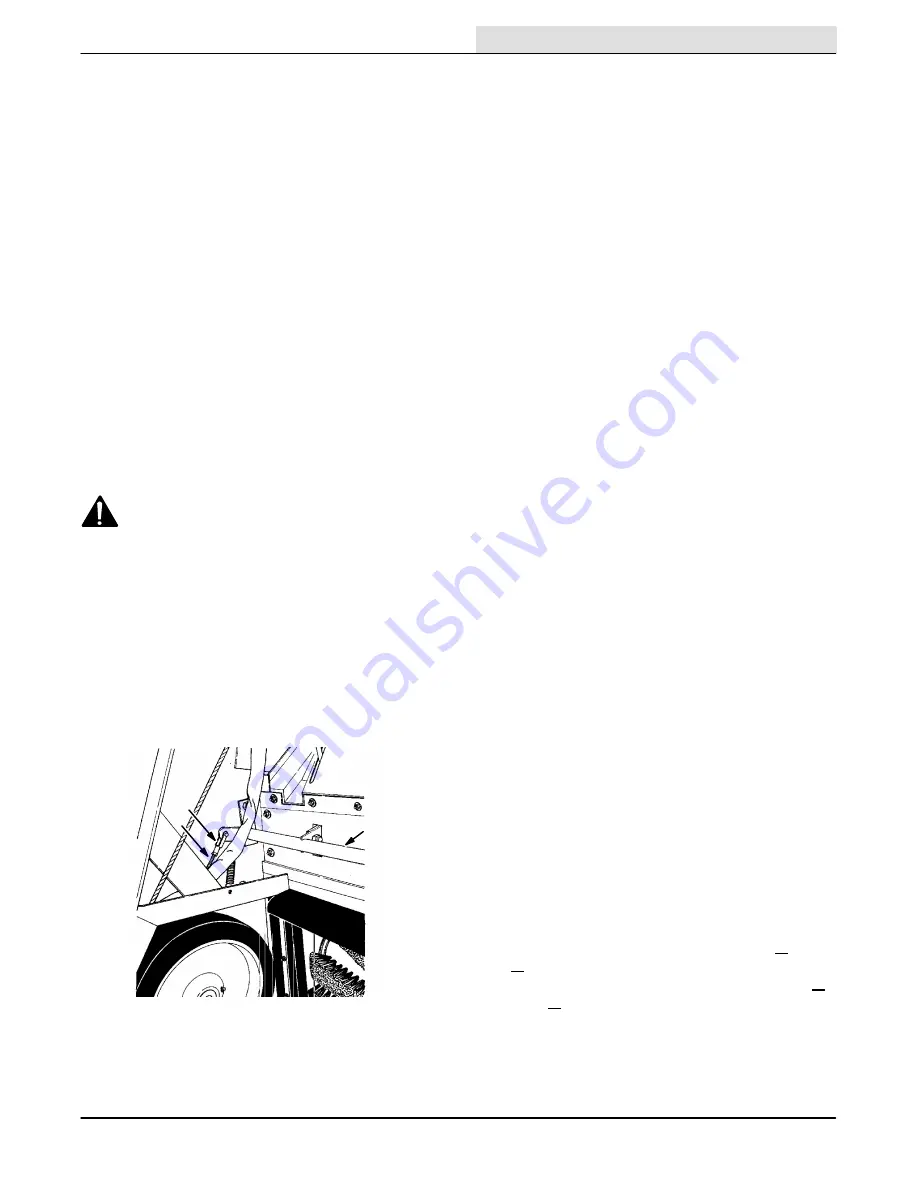

A

B

C

02457

BRAKE CLEVIS

A. Brake Adjusting Clevis

B. Threaded Rod

C. Brake Cross Shaft

7. Thread the clevis out to decrease brake pedal

height, or in to increase brake pedal height.

Both clevises must be turned the same

amount.

8. Adjust the brake linkage so that the brake

pedal travels no more than 1 in (25 mm) to fully

engage the brakes. If the brake pedal travels

more than 1 in (25 mm), it indicates the brake

clevises are not adjusted the same. Readjust

as necessary.

9. Reinstall the brake clevis pins.

10. Start the engine and raise the hopper.

11. Lower the hopper bar.

12. Lower the hopper and stop the engine.

13. Remove the machine tire blocks.

PARKING BRAKES

The parking brakes are engaged by the parking

brake lever which activates the service brake linkage.

The parking brakes should be adjusted whenever it

becomes very easy to engage the parking brake,

when the machine rolls after engaging the parking

brake, and after every 200 hours of operation. The

parking brake may be routinely tightened by turning

the knurled knob on the end of the parking brake

clockwise. If the knob adjustment is inadequate, fully

loosen the knob and adjust the brake linkage as

described in To Adjust Brake Linkage. Adjust the

parking brake so it will hold the machine on a

smooth 8

_

ramp.

TIRES

The standard front machine tires are solid.

The standard rear machine tire is pneumatic.

Check the tire pressure after every 100 hours of

operation. The proper tire air pressure is 80 + 5 psi

(550 + 35 kPa). When the machine is equipped with

a scrub attachment, the proper air pressure is 70 +

5 psi (480 + 35 kPa).

A solid rear tire is available as an accessory.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...