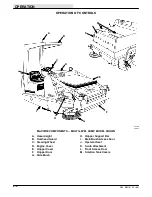

OPERATION

2-10

285 MM191 (12---89)

HOPPER LIFT AND SIDE BRUSH LEVER

The hopper lift and side brush lever controls the

hopper lift height and side brush rotation.

To lift the hopper, pull the lever back into the

(Hopper Up) position until the hopper reaches

the desired lift height. Be sure adequate vertical

clearance is available before lifting the hopper.

WARNING: Machine hopper lifts to 108 in

(2745 mm) when high dumping. Hopper can

hit overhead wires or object. Electrical shock or

falling debris can result. Be sure adequate

clearance is available before raising hopper.

To hold the hopper up, pull the lever all the way back

into the

(Hopper Hold) position. Do not rely on

the hydraulic system to keep the hopper raised if

work is to be done on the machine. Always engage

the hopper support bar.

WARNING: Falling hopper. Engage hopper

support bar before working under hopper.

To lower the hopper, push the lever into the

(Hopper Down) position.

To the start the side brush rotation, push the lever

into the

(Side Brush On) position. To stop the

side brush rotation, pull the lever into the (Hopper

Down) position.

MAIN BRUSH POSITION LEVER

The main brush position lever controls the position of

the main brush. There are two positions in which the

main brush may be operated. The positions are

normal and free-float. The normal sweeping position

is used for most sweeping conditions. Operating in

the normal position will extend main brush life. The

free-float position is used when sweeping extremely

uneven areas. The free-float position allows the main

brush to follow the uneven surfaces more closely.

To lower the main brush for normal sweeping

conditions, pull the lever back and to the left into the

(Main Brush Down) position.

To lower the main brush for sweeping extremely

uneven surfaces, pull the lever back and to the right

into the

(Main Brush Free Float) position.

To raise the main brush, pull the lever all the way

back and to the right into the

(Main Brush Up)

position.

NOTE: Always raise the main brush when the

machine is not being operated for a period of time to

prevent the main brush from taking a set.

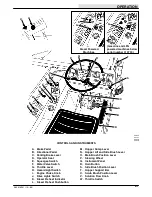

STEERING WHEEL

The steering wheel controls the rear wheel through

an arm and tie rod. The machine is very responsive

to steering wheel movements. Use care until you

become more experienced in guiding the machine.

A horn button is located in the center of the steering

wheel.

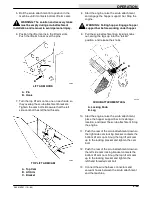

MAIN BRUSH HEIGHT ADJUSTMENT KNOB

The main brush height adjustment knob is located

behind an access door next to the operator’s left

foot. It limits how close to the ground the main brush

will operate when the main brush position lever is in

the “normal” position.

To raise the main brush and reduce the main brush

floor contact, loosen the wing nut and thread the

knob clockwise.

To lower the main brush and increase main brush

floor contact, loosen the locking knob and thread the

knob counter-clockwise. Retighten the wing nut after

making any adjustment.

A

B

00563

MAIN BRUSH HEIGHT ADJUSTMENT KNOB

A. Wing Nut

B. Adjustment Knob

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...