MAINTENANCE

285 MM191 (12---89)

3-24

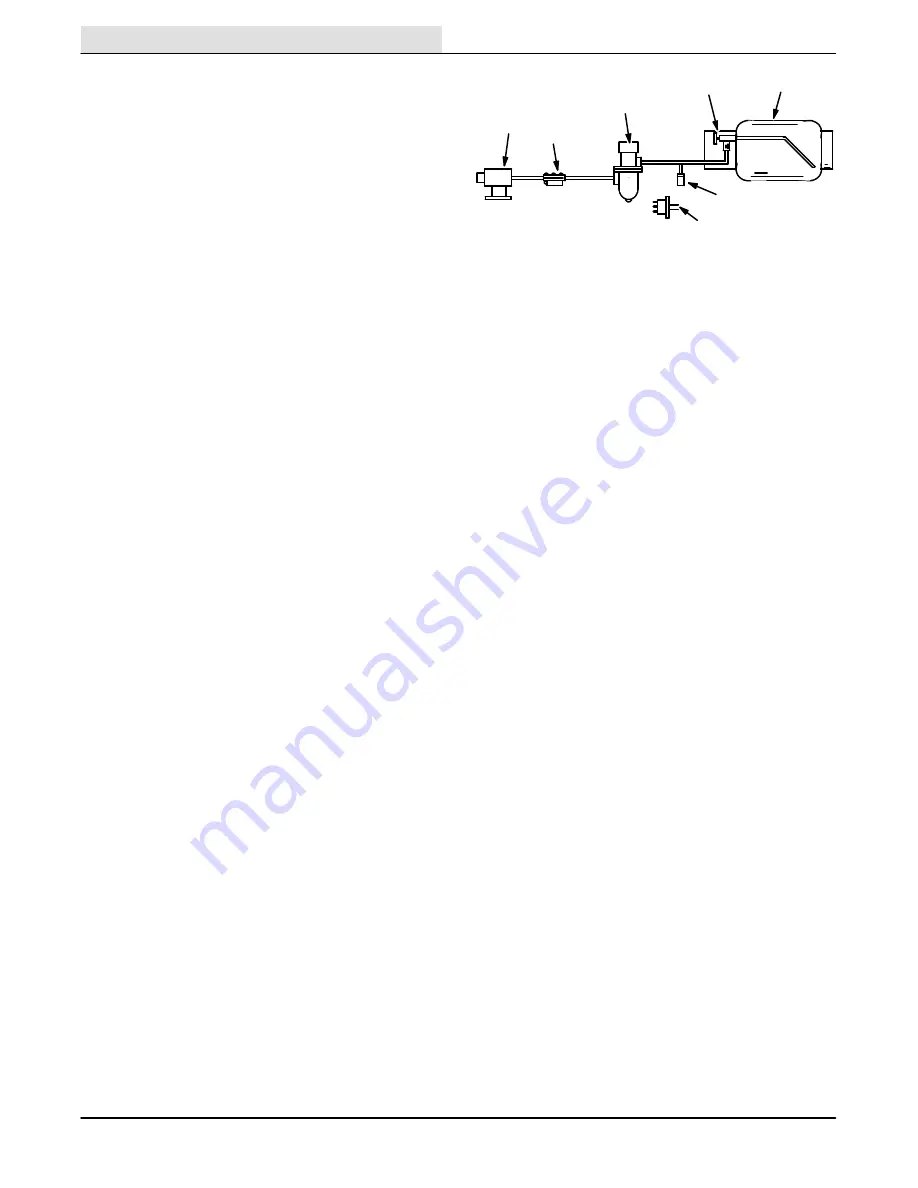

FUEL SYSTEM -- LPG

LPG FUEL SYSTEM

The liquid withdrawal LPG fuel system is made up of

five components which are: the LPG fuel tank,

pressure relief valve, fuel filter lock,

vaporizer-regulator, and the carburetor.

Liquid LPG fuel flows from the LPG tank, under its

own pressure, to the pressure relief valve. This valve

is normally closed, preventing LPG fuel from

escaping into the atmosphere. The valve opens to

relieve pressure if the fuel pressure exceeds system

limits. From the pressure relief valve, the liquid LPG

fuel is piped to the fuel filter lock.

The fuel filter lock filters unwanted tank scale and

deposits out of the LPG fuel. The fuel filter lock also

stops the flow of LPG fuel when the engine is not

operating. The oil pressure switch controls the fuel

filter lock. When the engine oil pressure is

5 psi (35 kPa) or greater, the oil pressure switch

permits an electrical current to open the fuel filter

lock which allows LPG fuel to flow on to the

vaporizer-regulator. The oil pressure switch is

bypassed when the engine is being started, allowing

LPG fuel to flow.

The vaporizer section of the vaporizer-regulator

converts the liquid LPG fuel into a gaseous LPG fuel.

From the vaporizer section, the gaseous LPG fuel is

sent to the primary regulator section of the

vaporizer-regulator. The primary regulator section

reduces the pressure of the LPG fuel. The secondary

regulator section reduces the LPG fuel pressure to

the level required by the carburetor. From the

vaporizer-regulator, the LPG fuel is sent to the

carburetor where it is finally metered into the air flow

which is sent to the engine combustion chamber.

A

B

C

D

E

F

G

03511

LPG FUEL SYSTEM

A. Carburetor

B. Vaporizer-Regulator

C. Fuel Filter Lock

D. Pressure Relief Valve

E. Tank Service Valve

F. LPG Fuel Tank

G. Oil Pressure Switch

Never operate an LPG powered machine if the LPG

fuel system is leaking, or if any component in the fuel

system is malfunctioning. Operating the machine

under either of these conditions may cause a fire or

explosion.

Check for frosting. Frosting does occur before the

engine reaches operating temperature. Check after

engine reaches operating temperature. If frosting

occurs on or near any LPG component, there is a

possibility of an LPG fuel leak or a malfunctioning

component.

To locate the leak, apply a soapy water solution to

the suspected area. Watch for bubbles forming in a

confined area. This area may have an LPG fuel leak.

Repair or replace the part. Use Loctite brand

Stainless Steel PST thread sealant when

reassembling. This epoxy-type sealant is not affected

by aging or high humidity. Be sure to follow

application directions and apply proper torque when

reconnecting fittings.

Never bypass safety components except to test. If

they are defective, replace them before operating the

machine.

Check routings of all LPG hoses. Keep them away

from sharp edges, exhaust manifolds, or other hot

surfaces. Check for signs of abrasion or

deterioration. Replace hoses found to be worn or

damaged.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...