IB 340513 (10-01)

2

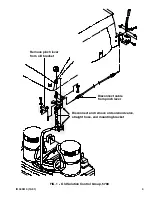

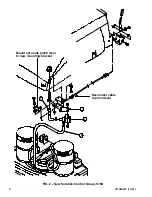

7. Assemble the new solenoid valve (2) to the new mounting bracket (1) with two hex screws

and lock nuts. Tighten hardware to 16--20 ft lbs.

(Refer to FIG. 2)

8. Mount 90

°

water hose (3) to the solenoid valve (2) with wormdrive clamp. Hand tighten the

wormdrive clamp with 5/16 nut driver.

(Refer to FIG. 2)

9. Assemble the set aside pinch lever to the new mounting bracket (1) with a nylon washer

(between the lever and bracket), hex screw, flat washer and lock nut. Hand tighten

hardware. The pinch lever should move with a slight tension.

(Refer to FIG. 2)

10. Mount the new solution valve (2) and bracket (1) assembly to the bottom of the solution

tank, in place of the old assembly. Tighten hardware to 16--20 ft lbs. Connect the 90

°

water

hose (3) to the tank with wormdrive clamp. Hand tighten the wormdrive clamp with 5/16 nut

driver.

(Refer to FIG. 2)

11. Connect the open end of the push pull cable to the pinch lever with the swivel and pan

screw. Hand tighten the securing hardware.

(Refer to FIG. 2)

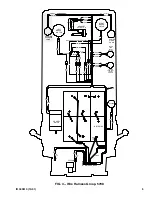

12. Connect the machine harness 47A/GRY and 13M/BLK to the new solenoid valve (2).

Secure the wire harness to the solenoid valve (2) with a plastic wire tie.

(Refer to FIG. 3 and 4)

13. Replace the front cover on the machine. Disengage the solution tank support rod and lower

the solution tank.

14. Check the machine and new solution control group for proper operation.

BILL OF MATERIALS FOR SOLUTION VALVE REPLACEMENT KIT 374754

TENNANT

Ref.

Part No.

Description

Qty.

1

397787

Bracket, mtg, valve

1

2

374752

Valve, solenoid

1

3

397777

Hose, rbr, E90, 0.62ID 0.81ID (valve)

1

4

374753

Hose, PVC

1

TENNANT COMPANY

P. O. Box 1452

Minneapolis, MN 55440-1452