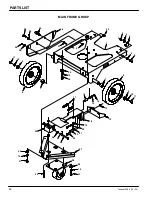

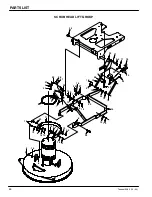

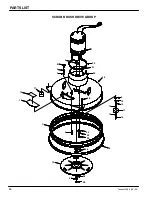

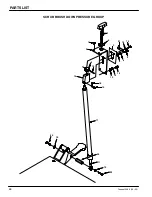

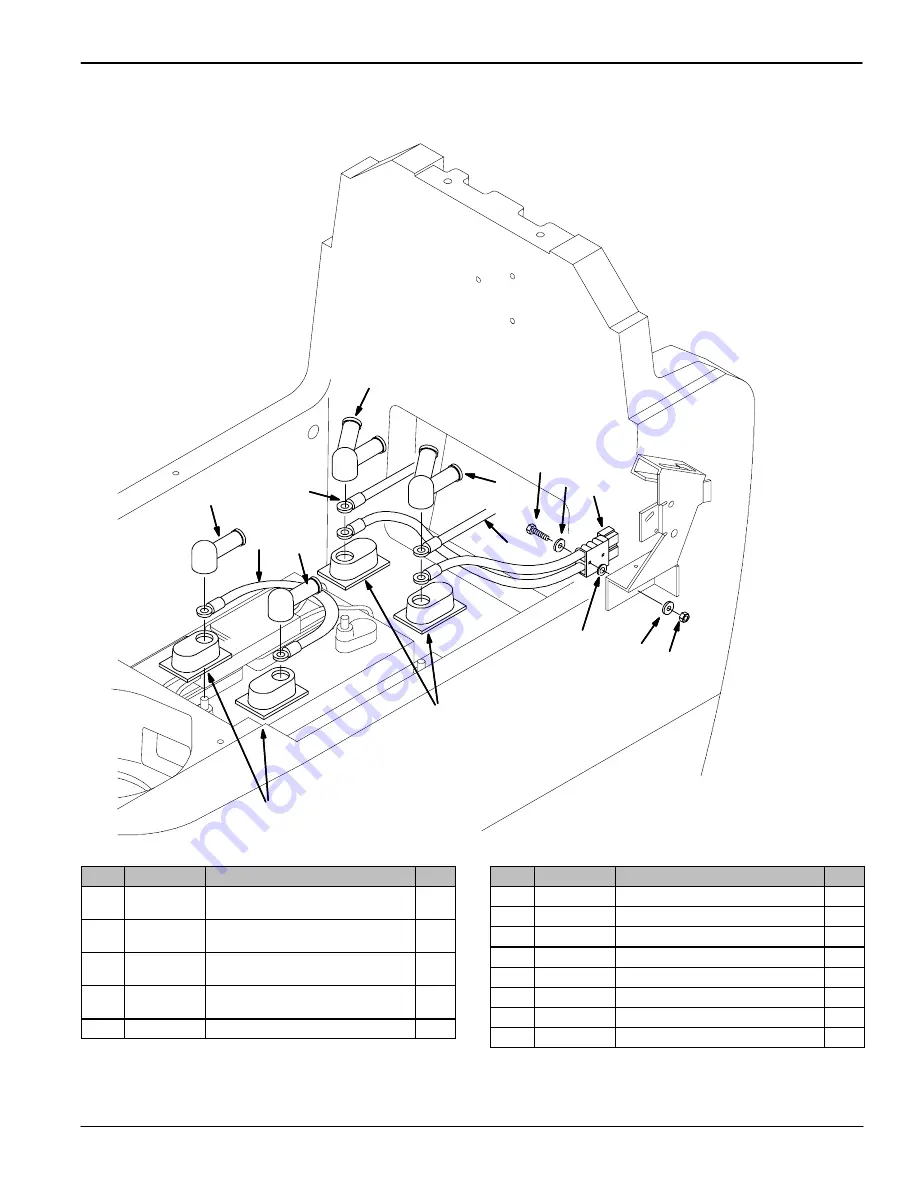

PARTS LIST

Tennant 5280 (10--04)

55

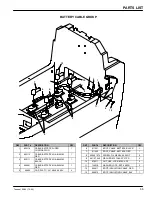

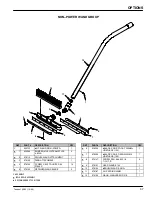

BATTERY CABLE GROUP

2

3

4

5

13

12

1

7

6

5

8

9

10

11

9

REF

PART #

DESCRIPTION

QTY.

1

630118

CABLE, BATTERY, W/RED

CHARGE PLUG

1

2

630110

CABLE, BATTERY, 4GA, 813MM,

RED

1

3

630111

CABLE, BATTERY, 4GA, 864MM,

BLACK

1

4

603061

CABLE, BATTERY, 6GA, 305MM,

RED

1

5

45962

CAP, PLSTC, .04 1.38X2.30 .05L

4

REF

PART #

DESCRIPTION

QTY.

6

611221

BOOT, CABLE, BATTERY, BLACK

1

7

611222

BOOT, CABLE, BATTERY, RED

1

8

200051274

SCREW, FIL, M3X.5X30, SLOT

2

9

601127000

WASHER, M3.7X8X.5 FLT ZN

4

10

579211

NUT, HEX, LOCK, M3X.5, SS

2

11

140019

WASHER, LOCK, EXT, #06 ZN

2

12

606011

BOOT, INSULATING CABLE, RED

1

13

606010

BOOT, INSULATING CABLE, BLK

1