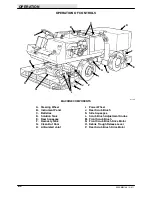

OPERATION

550E MM149 (3--91)

2-6

BRAKE PEDAL

The foot brake pedal operates the hydraulic disc

brakes on the two front wheels.

To stop the machine, return the directional pedal

to neutral; then apply pressure to the brake pedal.

DIRECTIONAL PEDAL

The machine is propelled by two electric motors

which drive the two front wheels. Traveling speed

of the machine is varied by means of a foot pedal

which is also used to select the direction of travel.

A

B

C

E

D

00116

DIRECTIONAL PEDAL

A. “Reverse” Position

B. “Neutral” Position

C. “Forward” Position

D. “Toe” Portion

E. “Heel” Portion

Gently press the “toe” portion of the pedal for

forward travel. Press the “heel” portion for reverse

travel. Regulate machine speed by varying the

pressure on the pedal.

There are six forward speeds; three level or

normal speeds and three climb speeds. There are

also three reverse speeds. As the directional

control pedal is pressed, the faster speed ranges

will engage--much like an automatic transmission.

There will be a three-second delay between the

time the speed switches are engaged and the

time the motor speeds up. This delay is present to

insure a smooth acceleration.

NOTE: For normal stopping, return the directional

pedal to neutral and use the foot brake to stop the

machine.

PARKING BRAKE LEVERS

The parking brake levers control brakes on all four

wheels. Pulling the brake handles up sets the

parking brakes. Pushing the brake handles down

releases the parking brakes. Always set the

parking brakes before leaving the machine

unattended and before working on the machine.

The parking brakes must be released in order to

start the machine motors.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

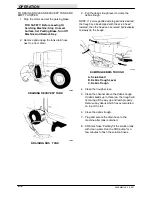

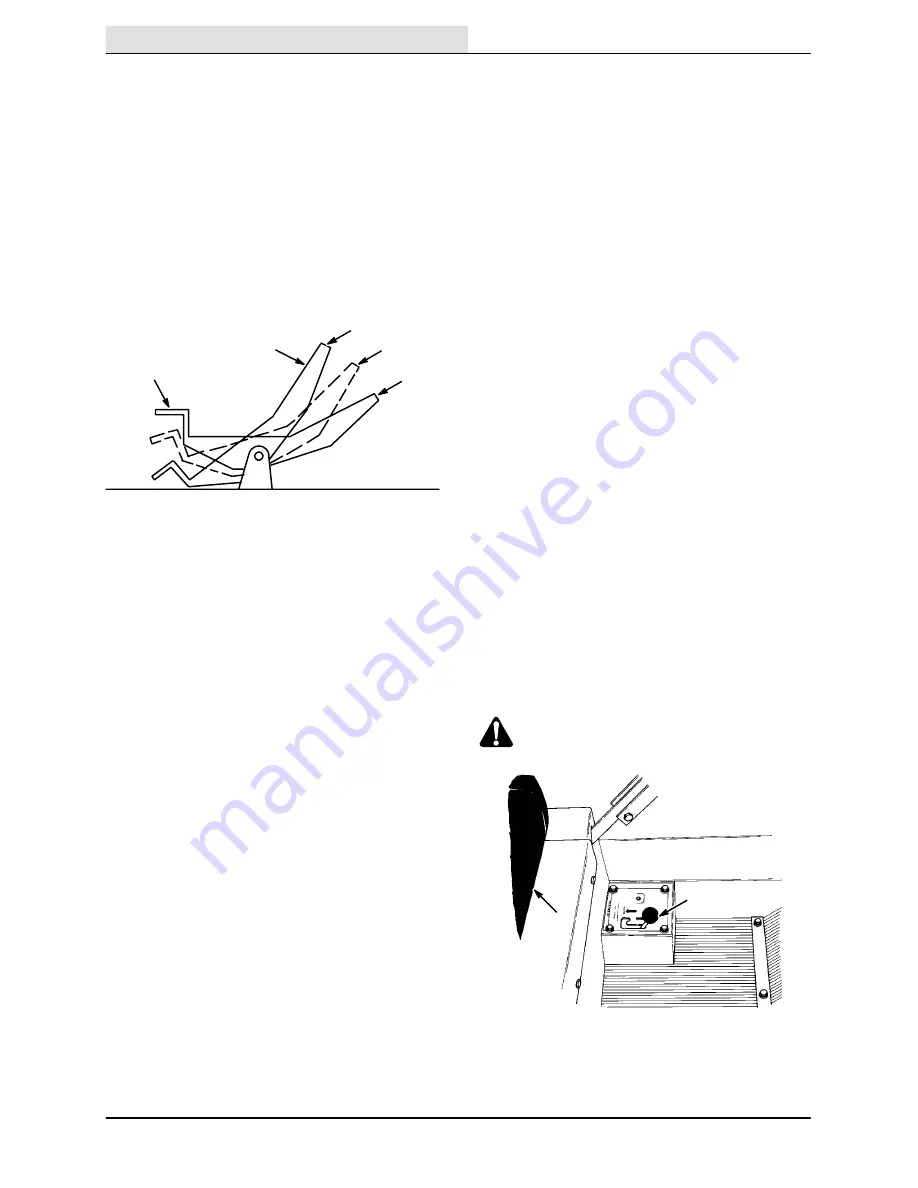

SCRUB HEAD LOCK LEVER

The scrub head lock lever controls the scrub head

lock mechanism. This locks the scrub head,

preventing it from lowering.

To set the scrub head lock, fully raise the scrub

head. Then push the scrub head lock lever into

the “LOCK” position.

To release the scrub head lock, fully raise the

scrub head. Then pull the scrub head lock lever

into the “UNLOCK” position.

Always set the scrub head lock before working

under the scrub head. The scrub head lock must

also be set whenever the machine will not be

used for an extended period of time, overnight for

example. Flat spots on the brushes will appear if

the scrub head is left down for an extended period

of time.

WARNING: Falling Scrub Head. Block

Scrub Head Up Before Working Under It.

B

A

01816

SCRUB HEAD LOCK LEVER

A. Operator Seat

B. Scrub Head Lock Lever

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...