OPERATION

550E MM149 (8--02)

2-8

DRAIN TANK LAMP (OPTION)

The drain tank lamp is present on machines

equipped with the drain tank option. The lamp

lights when the recovery tank is nearly full. The

machine operator can then plan to return to a

dumping station.

SQUEEGEE POSITION LAMP

The squeegee position lamp lights when the rear

squeegee is either fully raised or lowered. This

can be helpful to the operator when the squeegee

is not visible.

HOUR METER

The hour meter is located on the control panel.

The meter records the number of hours the

machine is operated and is useful in determining

when to perform periodic maintenance procedures

which are listed in the maintenance chart.

SCRUB BRUSH PRESSURE GAUGE

The scrub brush pressure gauge indicates the

electrical current flow to the rear scrub brush

motor. The gauge needle should be in the green

zone when scrubbing. If the needle stays in the

red zone continuously, the scrub brush pattern or

floor contact area is excessive and should be

decreased.

BATTERY CONDITION GAUGE

The battery condition gauge indicates the battery

state of charge. When the gauge needle is in the

red zone, the batteries should be recharged.

NOTE: If machine stalls due to low battery

charge, disconnect the vacuum fan belt and wait

approximately 5 to 10 minutes. The batteries

should then have recovered enough to be able to

power the machine to a charger station.

PANEL LAMP (OPTION)

The panel lamp is present on machines with the

operating lights option. The lamp lights whenever

the operating lights switch toggle is flipped up to

turn on the operating lights.

SCRUB BRUSH SWITCH

The scrub brush switch controls the power to the

scrub brush motors. Place the scrub brush switch

in the “on” position to start the scrub brushes

rotating. Place the switch in the “off” position to

stop scrub brush rotation.

The switch also provides the circuit electrical

overload protection with a 30 A circuit breaker.

In the event of a circuit overload, the switch will

return to the “off” position. The switch must then

be returned to the “on” position to restart the

scrub brush rotation. If the overload which caused

the switch to trip is still present, the switch circuit

breaker will continue to stop electrical current flow

until the overload is corrected.

NOTE: To prolong the life of the scrub brush

motors and chains, always raise the scrub head

before turning on brush drive motors.

SQUEEGEE SWITCH

The squeegee switch, in conjunction with a

hydraulic flow sensing device, controls the

position of the rear squeegee.

Flipping the switch toggle up places the rear

squeegee in the “Squeegee Up” position. This

position cannot be overridden by the hydraulic

flow sensing device.

Flipping the switch toggle down places the rear

squeegee in the “Down” position when traveling in

the forward direction. When traveling in the

reverse direction, the hydraulic flow sensing

device overrides the squeegee switch and raises

the rear squeegee. This prevents the rear

squeegees from being damaged when traveling in

reverse. The squeegee switch should always be

in the “Down” position when scrubbing.

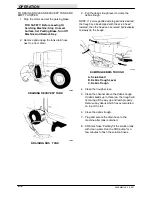

SCRUB HEAD POSITION CONTROL LEVER

The scrub head position control lever controls the

position of the scrub head lift cylinder. Pulling the

control lever into the “RAISE” position raises the

scrub head. The middle “HOLD” position stops

scrub head movement. Pushing the control lever

into the “LOWER” position lowers the scrub head.

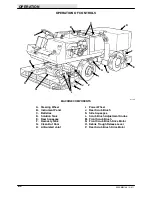

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...