MAINTENANCE

3-13

550E MM149 (6--96)

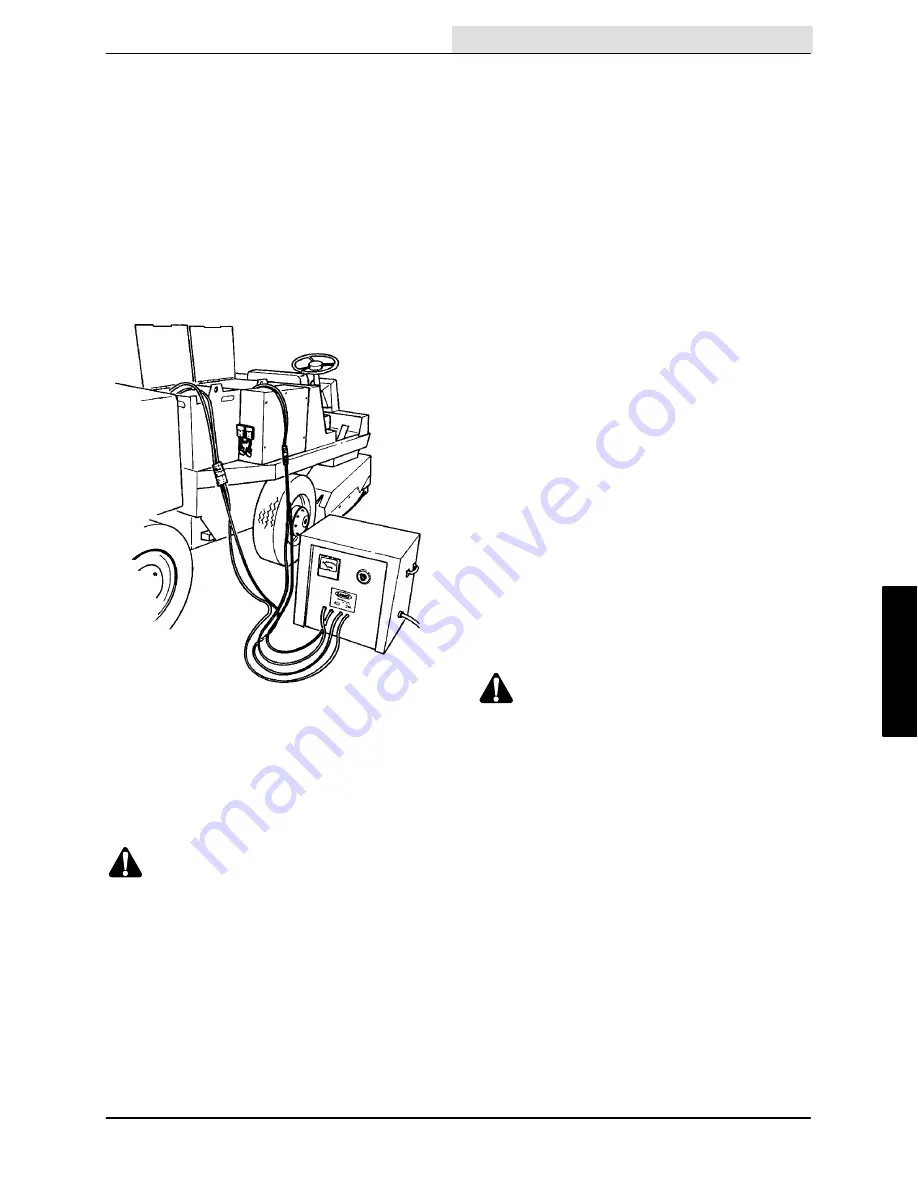

TO CHARGE BATTERIES

1. Turn charger timer to “off” position before

disconnecting or connecting batteries

receptacles to charger, and before inserting

or removing the “A.C.” plug from the wall

outlet.

2. Check water level in battery. Water should

cover plates completely. If water is low, add

distilled water, but do not over-fill.

3. Connect battery connectors to charger

connector.

01146

CHARGING MACHINE BATTERIES

4. Battery covers should be braced open, so

that the gases can escape. Otherwise, the

top of the battery eventually develops a

conductive leak between cells and battery

tray.

WARNING: Batteries Emit Hydrogen

Gas. Explosion Or Fire Can Result.

Keep Sparks And Open Flame Away.

Keep Covers Open When Charging.

5. Begin charge by turning timer to

recommended hours. Pilot light and

ammeter indicate charger is on.

6. Batteries are charged when timer reads “off”

or the electrolyte specific gravity indicates

100% charged.

NOTE: The charger may remain connected to the

batteries for occasional extended periods without

harm to the charger or batteries. The charging

rate gradually tapers down as the batteries are

recharged.

ELECTRIC MOTORS

The electric motor brushes should be inspected

and the brush dust should be blown out of the

motor after every 200 hours of operation. If the

brushes have been worn to less than 0.75 in

(20 mm) in length, they should be replaced. If the

commutator is worn or rough, the armature should

be removed. The commutator should be turned in

a lathe, the mica recut, and commutator polished.

Reassemble, and seat the new brushes, using a

brush seating stone. Be sure the rocker arm is set

on the neutral mark.

CONTROL PANEL

The control panel houses the forward and reverse

relays and controls. The components are not user

serviceable -- only trained personnel should be

allowed to work on it.

WARNING: Hazardous Voltage. Shock

Or Electrocution Can Result.

Disconnect Batteries Before Working

On Machine. Only Qualified Personnel

Should Work Inside Panel.

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...