MAINTENANCE

3-15

550E MM149 (6--96)

BELTS AND CHAINS

VACUUM FAN DRIVE BELT

The vacuum fan drive belt is driven by the main

electric motor. Belt tension is maintained by a

tension spring. The belt is properly tensioned

when the spring is extended 1.25 in (32 mm)

beyond it’s collapsed length, approximately

6.88 in (175 mm). Thread the spring eye bolt in or

out of the fan mounting bracket to change the

spring length. Check belt condition and tension

after every 50 hours of operation.

WARNING: Strong Vacuum. Keep Away

From Fan Inlet When Fan Is Running.

WARNING: Moving Belt. Keep Away.

PUMP DRIVE BELT

The pump drive belt is driven by the main electric

motor. Belt tension is maintained by an

adjustment bolt that pivots the pump assembly

away from the electric motor. The belt is properly

tensioned when it deflects 0.12 in (3 mm) from a

force of 1.5 to 2 lb (0.7 to 0.9 kg) applied at belt

midpoint. Check belt tension after every 50 hours

of operation.

WARNING: Moving Belt. Keep Away.

STATIC DRAG CHAIN

A static drag chain is provided to prevent the

build-up of static electricity in the machine. This

chain is attached below the machine frame, and

drags on the floor.

Check the chain periodically for wear. Make sure

that it is making contact with the floor at all times.

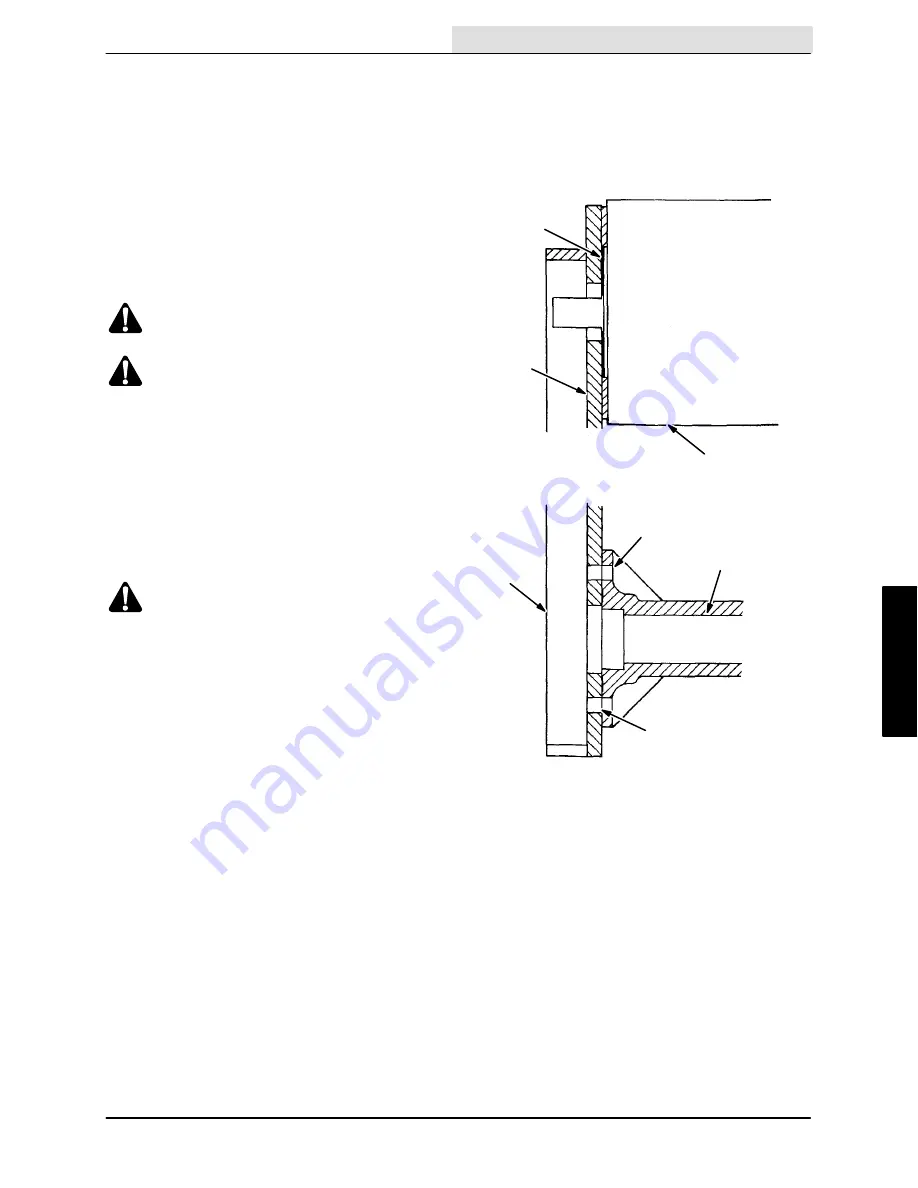

SCRUB BRUSH DRIVE CHAINS

Each of the two scrub brush drive chains are

driven by an electric motor. The chains are

covered by a chain case and are partially

immersed in SAE 30 engine oil. Check the oil

level after every 50 hours of operation.

Chain tension is adjusted by moving the mounting

location of the electric motors. The motor

mounting holes are slotted. The chains are

properly tensioned when there is 0.12 in (3 mm)

slack midway between the sprockets. Check the

chain tension after every 100 hours of operation.

When replacing drive chains, be sure to use new

gaskets and RTV sealant where they were

originally used. Also, use Loctite on the four motor

mounting bolts.

A

B

C

D

E

F

G

01151

SCRUB BRUSH DRIVE CROSS-SECTION

A. Gasket

B. RTV Sealant in Slot after the

Bolt is in Place

C. Electric Motor

D. Loctited Mounting Bolts (4)

E. Bearing Housing

F. Brush Drive Arm

G. Sealant Around the Diameter

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...