MAINTENANCE

3-19

550E MM149 (6--96)

SCRUB BRUSHES

The scrub brushes are tubular and run the width

of the scrub head, sweeping debris into the debris

trough while they scrub the floor. The brushes

should be inspected daily for damage or wear.

Remove any string or wire found tangled on the

scrub brushes, drive, or idler hubs.

Rotate the scrub brushes from front-to-rear after

every 50 hours of operation for maximum brush

life and best scrubbing performance.

The scrub brush patterns should be checked

daily. The scrub brush pattern is adjusted by

turning the adjustment knobs on top of the scrub

head. See

TO ADJUST SCRUB BRUSH

PATTERN

. The width of the patterns should be

1.5 to 2 in (40 to 50 mm).

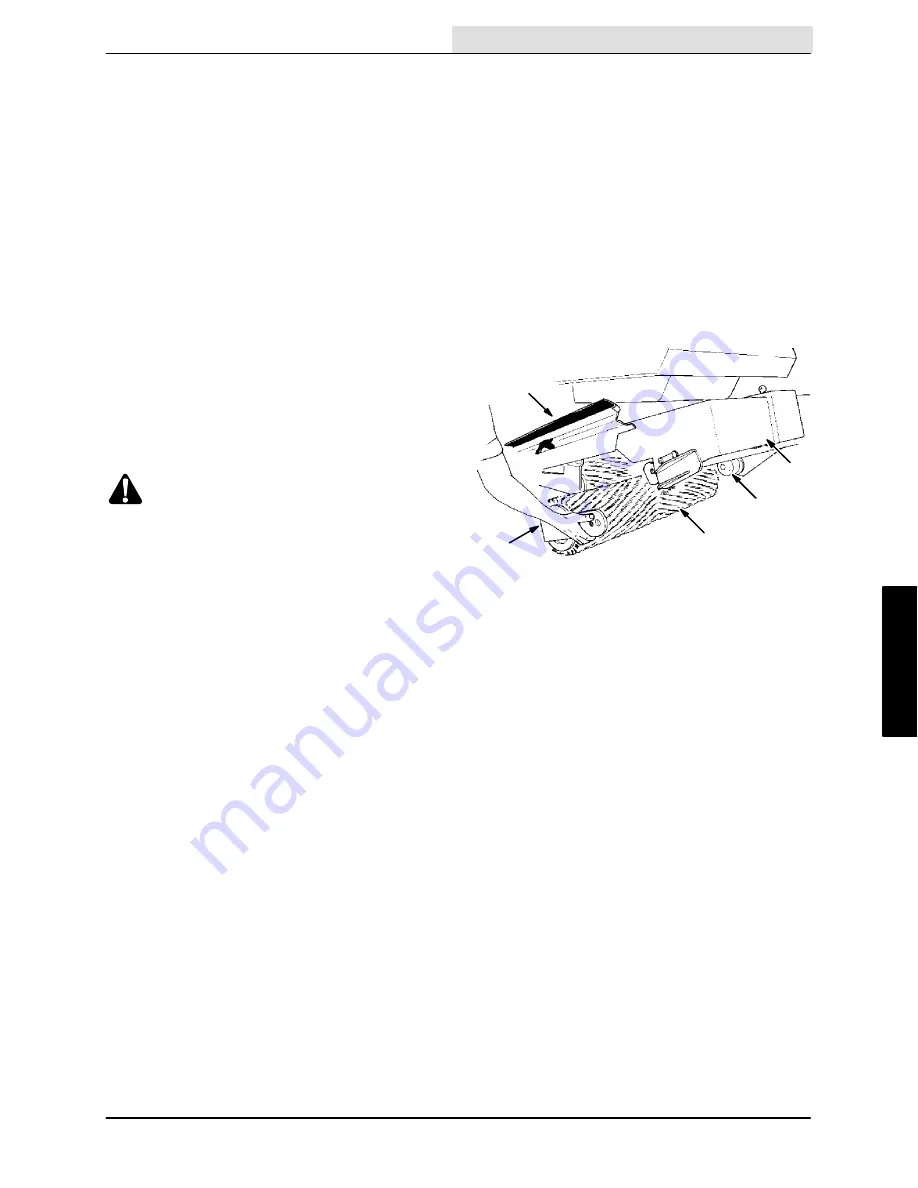

TO REPLACE SCRUB BRUSHES

1. Raise scrub head and set scrub head lock.

WARNING: Falling Scrub Head. Block

Scrub Head Up Before Working Under It.

2. Stop motor and set parking brake.

FOR SAFETY: Before Leaving Or

Servicing Machine; Stop On Level

Surface, Set Parking Brake, Turn Off

Machine And Remove Key.

3. Open right side door on scrub head and use

the chain to hold the door in the raised

position.

4. Use wrench to remove hex head bolt

attaching the brush arm.

NOTE: If arm does not come off easily, insert bolt

in the adjacent threaded hole and screw in until

arm comes off.

5. The brush arm and brush can then be pulled

out.

6. Repeat step 4 and 5 to remove other brush.

7. Insert one end of brush through access door

and push the brush in until it touches the

drive plug.

It is helpful to have a second person guide

the other brush end onto the drive plug while

you are pushing and turning the brush until it

engages the drive keyway on the plug.

8. Install the brush arm with the hex head bolt.

E

D

C

A

B

00287

REPLACING BRUSH

A. Door

B. Brush Arm

C. Brush

D. Brush Drive Plug

E. Raised Scrubber Head

9. Repeat steps 7 and 8 for the other brush.

10. Unhook the chain and lower the access

door.

11. Release the scrub head lock before lowering

scrub head.

Summary of Contents for 550

Page 10: ...GENERAL INFORMATION 550E MM149 3 94 viii ...

Page 12: ...OPERATION 550E MM149 3 91 2 2 ...

Page 30: ...OPERATION 550E MM149 9 00 2 20 ...

Page 32: ...MAINTENANCE 550E MM149 3 91 3 2 ...

Page 62: ...MAINTENANCE 550E MM149 2 05 3 32 ...

Page 66: ...APPENDIX 550E MM149 3 91 4 4 ...

Page 74: ...STANDARD PARTS 550E MM149 5 01 6 4 Fig 2 Replacement Brushes 1 ...

Page 96: ...STANDARD PARTS 550E MM149 5 01 6 26 Fig 17 Electric Motor Group 1 2 3 4 5 6 ...

Page 105: ...STANDARD PARTS 6 35 550E MM149 5 01 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 106: ...STANDARD PARTS 550E MM149 5 01 6 36 Fig 23 Electrical Schematic 1 2 3 4 5 01228 550E ...

Page 117: ...STANDARD PARTS 6 47 550E MM149 5 01 Fig 31 Hydraulic Schematic 001330 005607 02361 550E ...

Page 118: ...STANDARD PARTS 550E MM149 5 01 6 48 Fig 32 Hydraulic Schematic 005608 11118 550E ...

Page 168: ...OPTIONS 550E MM149 9 99 8 18 ...

Page 182: ...BREAKDOWNS 550E MM149 10 10 9 14 ...