EN

ENGLISH

6

BR2020/T (04–98)

MACHINE SETUP

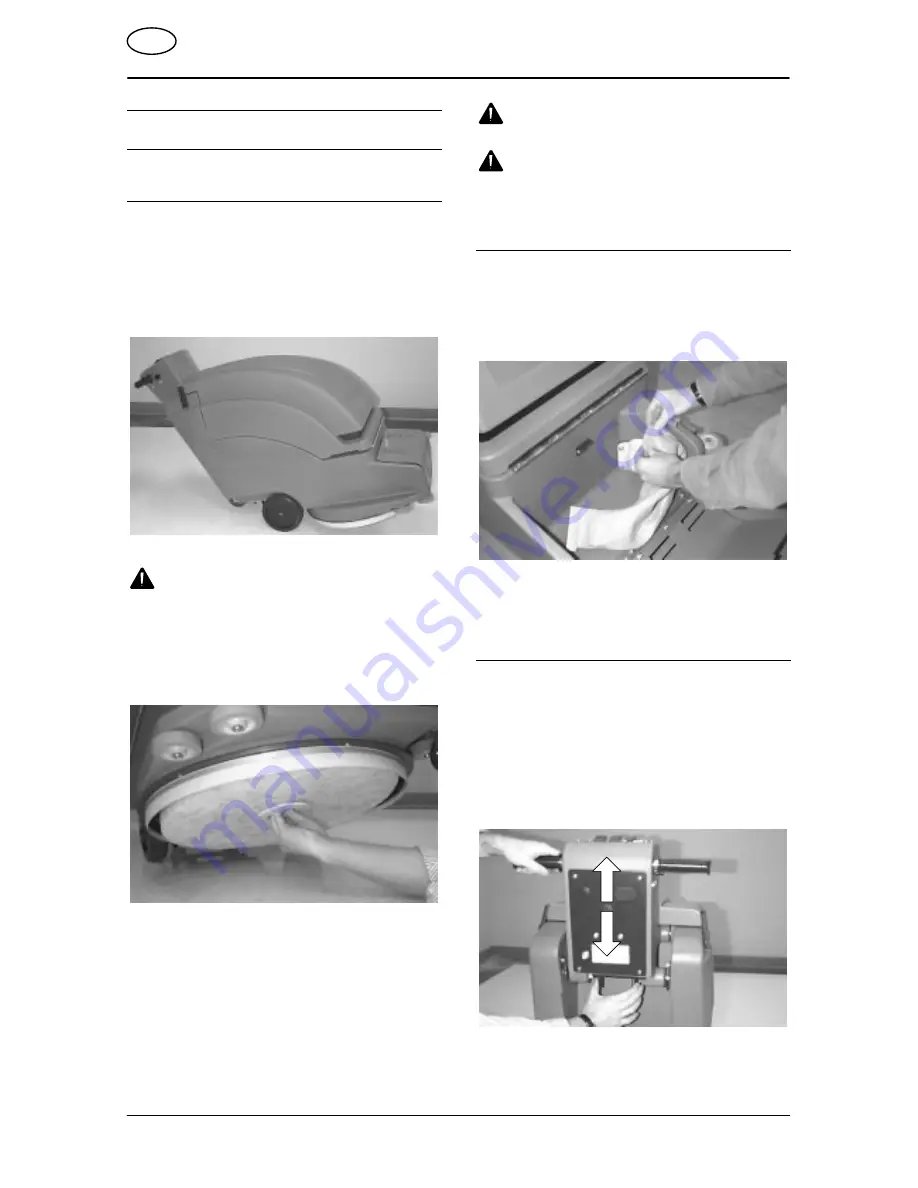

INSTALLING PAD

1.

Turn off key and tilt machine back on rear

wheels.

FOR SAFETY: When machine is tilted back it

will automatically shut off power to pad

motor.

Tilt Machine back to Install Pad

CAUTION: Do not leave machine tilted

back for an extended time, battery acid may

leak.

2.

Remove plastic center lock from pad driver by

turning lock counterclockwise.

3.

Position pad centered on pad driver and

replace centerlock securely.

Installing Pad

IMPORTANT: Consult your authorized

distributor for pad recommendations.

Pad Specifications:

For 2000 RPM Burnishing.

1”/25,4 mm Thickness

20”/508mm Diameter with 3.5”/89mm center hole.

NOTE:

Machine is not designed for spray buffing.

CAUTION: Make sure centerlock does not

cross thread or floor damage may occur.

CAUTION: Do not operate machine

without a pad and/or centerlock in place.

4.

Return machine to operating position.

INSTALLING DUST CONTROL BAG

1.

Open dust control bag compartment at front

of machine.

2.

Slide bag on plastic snout. Close

compartment.

Installing Dust Control Bag

3.

Empty or replace bag daily. Do not allow bag

to fill beyond half full.

ADJUSTING CONTROL GRIP HEIGHT

The machine has three control grip height

settings.

1.

Locate two spring loaded levers below

console.

2.

Squeeze levers together and lift or lower

control grips to a comfortable operating

height.

Adjusting Control Grip Height