ELECTRICAL

4--34

6100 G/LP 330235 (9--00)

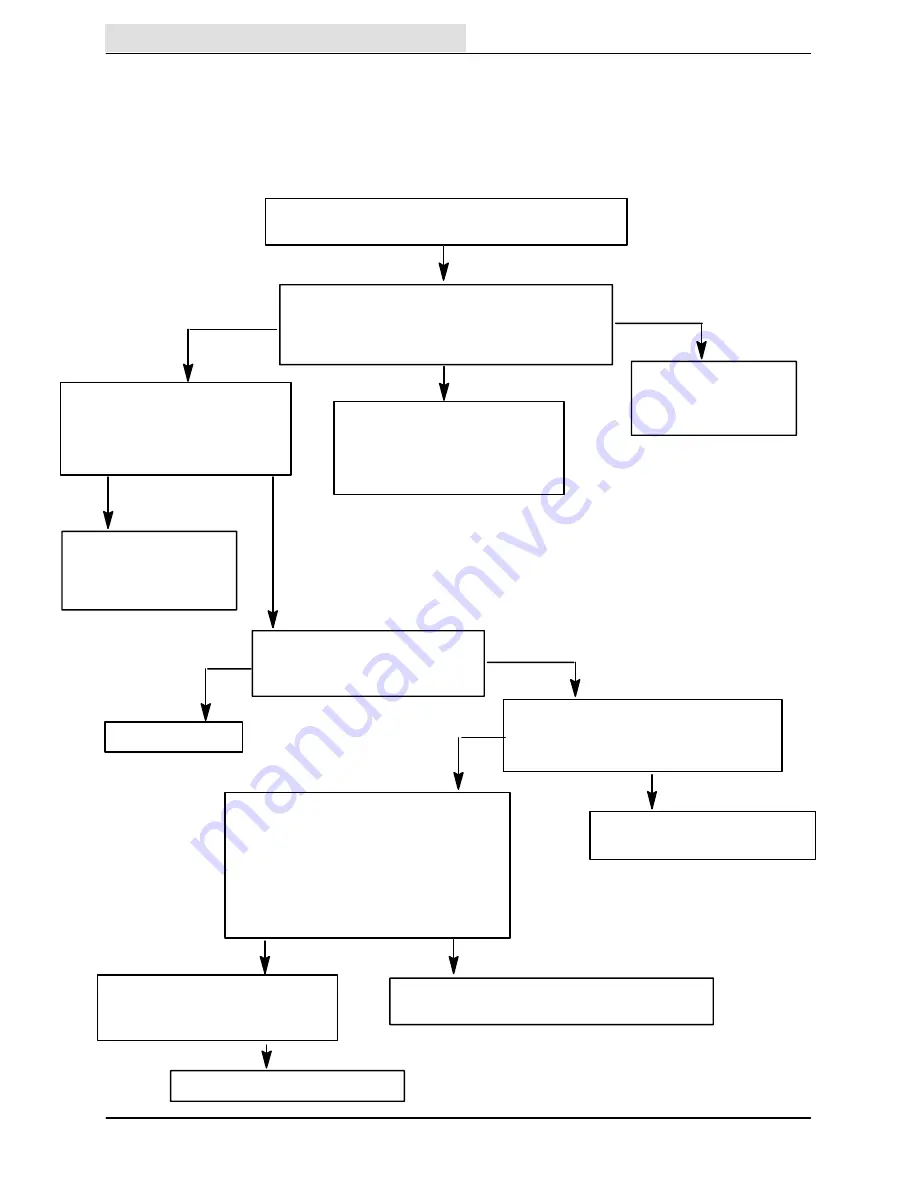

BATTERY NOT CHARGING (ALTERNATOR LIGHT IS ON)

NORMAL OPERATION:

1. Engine stator puts out 22 VAC at 2400 rpm.

2. The voltage regulator rectifies 22 VAC down to 13--15 VDC.

3. The 13--15 VDC output from the voltage regulator charges the battery.

CHECK BATTERY CONDITION. CHARGE AND

ADD WATER IF NECESSARY. CLEAN BATTERY TERMINAL.

ENGINE IS OFF

CHECK VOLTAGE FROM POSITIVE BATTERY POST

TO NEGATIVE POST (SHOULD BE ABOUT 12VDC

START ENGINE AND RECHECK VOLTAGE

GREATER THAN 15VDC

13--15VDC

VOLTAGE REGULATOR

NOT RECTIFYING THE

22VAC PROPERLY. RE-

PLACE RECTIFIER.

THE AC STATOR AND VOLTAGE

REGULATOR

ARE OPERATING PROPERLY.

TEST AND/OR REPLACE BATTERY.

IF ALT LIGHT IS ON, REPLACE THE

VOLTAGE REGULATOR.

NO INCREASE IN VOLTAGE

WITH KEY SWITCH IN THE RUN POSI-

TION,

BUT ENGINE OFF, CHECK VOLTAGE

ON 1A/RED AND 10J/GRY AT VOLTAGE

REGULATOR

0VDC

B+ VOLTAGE

WIRE 1A/RED, 10J/GRY,

8/BLU, CB--3, OR THE KEY

SWITCH IN RUN POSI-

TION FROM PIN B TO PIN

1G OPEN

CHECK VOLTAGE FROM BATTERY

POSITIVE TO 13A/BLK AT VOLTAGE

REGULATOR.

0VDC

13A/BLK IS OPEN

B+ VOLTAGE

PUT MULTIMETER IN AC MODE. MEASURE

AC VOLTAGE BETWEEN WIRES 12A/BRN

AND 11A/ORA AT VOLTAGE REGULATOR

WITH ENGINE RUNNING AT 2400RPM.

ABOUT 22VAC

AC STATOR OUTPUT IS GOOD

REPLACE VOLTAGE REGULATOR

LESS THAN 18VAC

REMOVE D1 AND D2, CHECK CONTINUITY

OF WIRE 12A/BRN, 12/BRN, 11A/ORA, AND

11/ORA. REPAIR OPEN WIRES. ALSO, DIS-

CONNECT THESE WIRES FROM VOLTAGE

REGULATOR AND STATOR OUTPUT. VERIFY

THEY ARE NOT SHORTED TO MACHINE

GROUND. REPAIR SHORTED WIRES. RE-

CONNECT AND RE--MEASURE AC VOLTAGE

AT REGULATOR.

STILL LESS THAN 18VAC

REPLACE VOLTAGE REGULATOR, IT

MAY BE PULLING AC STATOR OUTPUT

VOLTAGE DOWN.

ABOUT 22VAC

SYSTEM IS NOW WORKING. REPLACE D1 AND D2

SO HOUR METER OPERATES PROPERLY.

STILL LESS THAN 18VAC

REPLACE AC STATOR ON ENGINE

Summary of Contents for 6100 G/LP

Page 1: ...330235 Rev 02 9 01 Service Manual 6100 G LP ...

Page 4: ...GENERAL INFORMATION 1 2 6100 G LP 330235 9 01 ...

Page 18: ...CHASSIS 2 2 6100 G LP 330235 9 00 ...

Page 27: ...CHASSIS 2 11 6100 G LP 330235 9 00 7 Remove the hub assembly from the tire assembly ...

Page 72: ...CHASSIS 2 56 6100 G LP 330235 9 00 ...

Page 74: ...SWEEPING 3 2 6100 G LP 330235 9 00 ...

Page 152: ...ELECTRICAL 4 2 6100 G LP 330235 9 00 ...

Page 175: ...ELECTRICAL 4 25 6100 G LP 330235 9 01 ...

Page 176: ...ELECTRICAL 4 26 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC GAS 1 2 3 4 ...

Page 177: ...ELECTRICAL 4 27 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC GAS 1 2 3 4 ...

Page 178: ...ELECTRICAL 4 28 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC LP 1 2 3 4 ...

Page 179: ...ELECTRICAL 4 29 6100 G LP 330235 9 01 ELECTRICAL SCHEMATIC LP 1 2 3 4 ...

Page 180: ...ELECTRICAL 4 30 6100 G LP 330235 9 01 WIRE DIAGRAM GAS LP ...

Page 181: ...ELECTRICAL 4 31 6100 G LP 330235 9 01 WIRE DIAGRAM GAS LP ...

Page 182: ...ELECTRICAL 4 32 6100 G LP 330235 9 01 ...

Page 190: ...ELECTRICAL 4 40 6100 G LP 330235 9 00 ...

Page 192: ...HYDRAULICS 5 2 6100 G LP 330235 9 00 ...

Page 198: ...HYDRAULICS 5 8 6100 G LP 330235 9 00 9 Disengage the prop rod and close the seat support ...

Page 205: ...HYDRAULICS 5 15 6100 G LP 330235 9 00 10 Disengage the seat rod and close the seat assembly ...

Page 217: ...HYDRAULICS 5 27 6100 G LP 330235 9 00 HYDRAULIC SCHEMATIC ...

Page 218: ...HYDRAULICS 5 28 6100 G LP 330235 9 00 OUT IN B A B A HYDRAULIC HOSE DIAGRAM ...

Page 220: ...HYDRAULICS 5 30 6100 G LP 330235 9 00 ...

Page 221: ......

Page 222: ......

Page 223: ......

Page 224: ......

Page 225: ......

Page 226: ......

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 231: ......

Page 232: ......

Page 233: ......

Page 234: ......

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 252: ...ENGINE GAS LP 6 2 6100 G LP 330235 9 00 ...