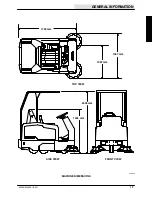

GENERAL INFORMATION

1-13

6200D 330395 (8--99)

HARDWARE INFORMATION

The following charts state standard plated

hardware tightening ranges for normal assembly

applications. Decrease the specified torque by

20% when using a thread lubricant. Do not

substitute lower grade hardware for higher grade

hardware. If higher grade hardware than specified

is substituted, tighten only to the specified

hardware torque value to avoid damaging the

threads of the part being threaded into, as when

threading into speed nuts or weldments.

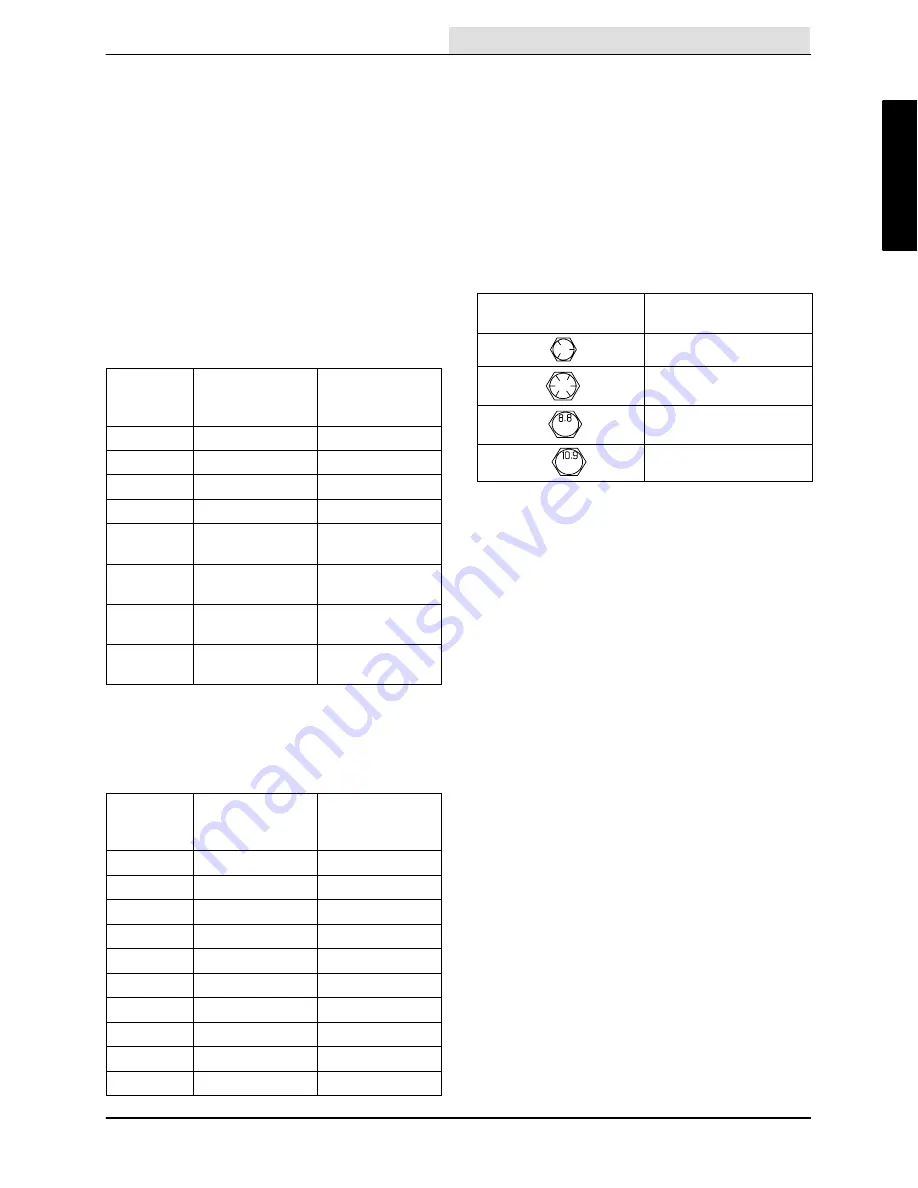

STANDARD BOLT TORQUE CHART

Thread

Size

SAE Grade 5

Torque ft lb

(Nm)

SAE Grade 8

Torque ft lb

(Nm)

0.25 in

7--10 (9--14)

10--13 (14--38)

0.31 in

15--20 (20--27)

20--26 (27--35)

0.38 in

27--35 (37--47)

36--47 (49--64)

0.44 in

43--56 (58--76)

53--76 (72--103)

0.50 in

65--85 (88--115)

89--116

(121--157)

0.62 in

130--170

(176--231)

117--265

(159--359)

0.75 in

215--280

(291--380)

313--407

(424--552)

1.00 in

500--650

(678--881)

757--984

(1026--1334)

NOTE: Decrease torque by 20% when using a

thread lubricant.

METRIC BOLT TORQUE CHART

Thread

Size

Class 8.8

Torque ft lb

_Nm)

Class 10.9

Torque ft lb

(Nm)

M4

2 (3)

3 (4)

M5

4 (5)

6 (8)

M6

7 (9)

10 (14)

M8

18 (24)

25 (34)

M10

32 (43)

47 (64)

M12

58 (79)

83 (112)

M14

94 (127)

133 (180)

M16

144 (195)

196 (265)

M20

260 (352)

336 (455)

M24

470 (637)

664 (900)

NOTE: Decrease torque by 20% when using a

thread lubricant.

Exceptions to the above chart:

Check the machine for exceptions!

BOLT IDENTIFICATION

Identification

Grade Marking

Specification and

Grade

SAE--Grade 5

SAE--Grade 8

ISO--Grade 8.8

ISO--Grade 10.9

01395

THREAD SEALANT AND LOCKING

COMPOUNDS

Thread sealants and locking compounds may be

used on this machine. They include the following:

Locktite 515 sealant -- gasket forming

material. TENNANT Part No. 75567,15 oz

(440 ml) cartridge.

Locktite 242 blue -- medium strength thread

locking compound. TENNANT Part No.

32676, 0.5 ml tube.

Locktite 271 red -- high strength thread

locking compound. TENNANT Part No.

19857, 0.5 ml tube.

Summary of Contents for 6200D

Page 1: ...330395 Rev 01 6 02 Service Manual 6200D 330395 ...

Page 4: ...GENERAL INFORMATION 1 2 6200D 330395 8 99 ...

Page 18: ...GENERAL INFORMATION 1 16 6200D 330395 8 99 ...

Page 20: ...CHASSIS 2 2 6200D 330395 8 99 ...

Page 74: ...CHASSIS 2 56 6200D 330395 8 99 ...

Page 76: ...SWEEPING 3 2 6200D 330395 8 99 ...

Page 138: ...SWEEPING 3 64 6200D 330395 6 02 ...

Page 140: ...ELECTRICAL 4 2 6200D 330395 8 99 ...

Page 176: ...ELECTRICAL 6200D 330395 6 02 4 38 ELECTRICAL SCHEMATIC 353188 D ...

Page 177: ...ELECTRICAL 4 39 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 178: ...ELECTRICAL 6200D 330395 6 02 4 40 WIRE HARNESSES GROUP 352986 353189 D ...

Page 179: ...ELECTRICAL 4 41 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 180: ...ELECTRICAL 6200D 330395 6 02 4 42 WIRE HARNESSES GROUP 352986 353189 D ...

Page 181: ...ELECTRICAL 4 43 6200D 330395 6 02 WIRE HARNESSES GROUP 352986 353189 D ...

Page 182: ...ELECTRICAL 6200D 330395 6 02 4 44 WIRE HARNESSES GROUP 352986 353189 D ...

Page 184: ...HYDRAULICS 5 2 6200D 330395 8 99 ...

Page 212: ...HYDRAULICS 5 30 6200D 330395 8 99 HYDRAULIC SCHEMATIC PROPEL ...

Page 213: ...HYDRAULICS 5 31 6200D 330395 8 99 HYDRAULIC SCHEMATIC HOPPER LIFT ...

Page 214: ...HYDRAULICS 5 32 6200D 330395 6 02 OUT IN B A B A 2 3 4 5 6 1 HYDRAULIC HOSE DIAGRAM PROPEL ...

Page 215: ...HYDRAULICS 5 33 6200D 330395 6 02 HYDRAULIC HOSE DIAGRAM HOPPER LIFT ...

Page 220: ...2 2 General Purpose Motors ...

Page 227: ......

Page 228: ......

Page 229: ......

Page 230: ......

Page 248: ...ENGINE DIESEL 6 2 6200D 330395 8 99 ...