OPERATION

17

810D MM310 (6--94)

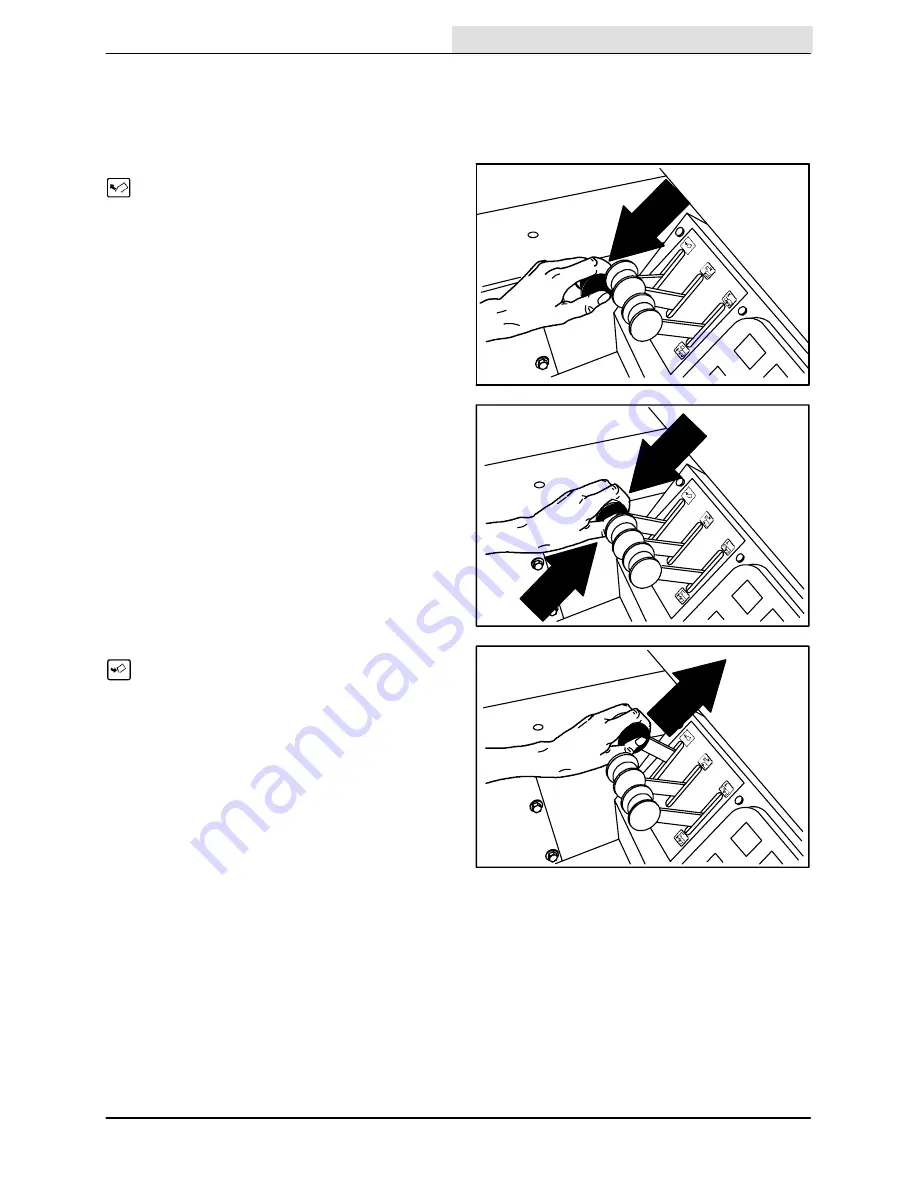

HOPPER DOOR LEVER

The hopper door lever opens and closes the

hopper door. Close the hopper door when

emptying the hopper to control debris and dust.

Open: Pull and hold the hopper door lever in the

Open

position.

Hold: Release the hopper door lever into the

middle position.

Close: Push and hold the hopper door lever in the

Close

position.

08474

08475

08476