MAINTENANCE

63

8400D MM312 (2–94)

Tennant’s hydraulic fluids provide a longer life for

the hydraulic components. There are two fluids

available for different temperature ranges:

Tennant part no.

Ambient Temperature

65869

above 7

C (45

F)

65870

below 7

C (45

F)

The higher temperature fluid has a higher

viscosity and should not be used at the lower

temperatures. Damage to the hydraulic pumps

may occur because of improper lubrication.

The lower temperature fluid is a thinner fluid for

colder temperatures.

If a locally-available hydraulic fluid is used, make

sure the specifications match Tennant hydraulic

fluid specifications. Using substitute fluids can

cause premature failure of hydraulic components.

European manufactured machines are filled with

locally available hydraulic fluids. Check the label

on the hydraulic fluid reservoir.

ATTENTION! Hydraulic components

depend on system hydraulic fluid for

internal lubrication. Malfunctions,

accelerated wear, and damage will result

if dirt or other contaminants enter the

hydraulic system.

HYDRAULIC HOSES

Check the hydraulic hoses every 800 hours of

operation for wear or damage.

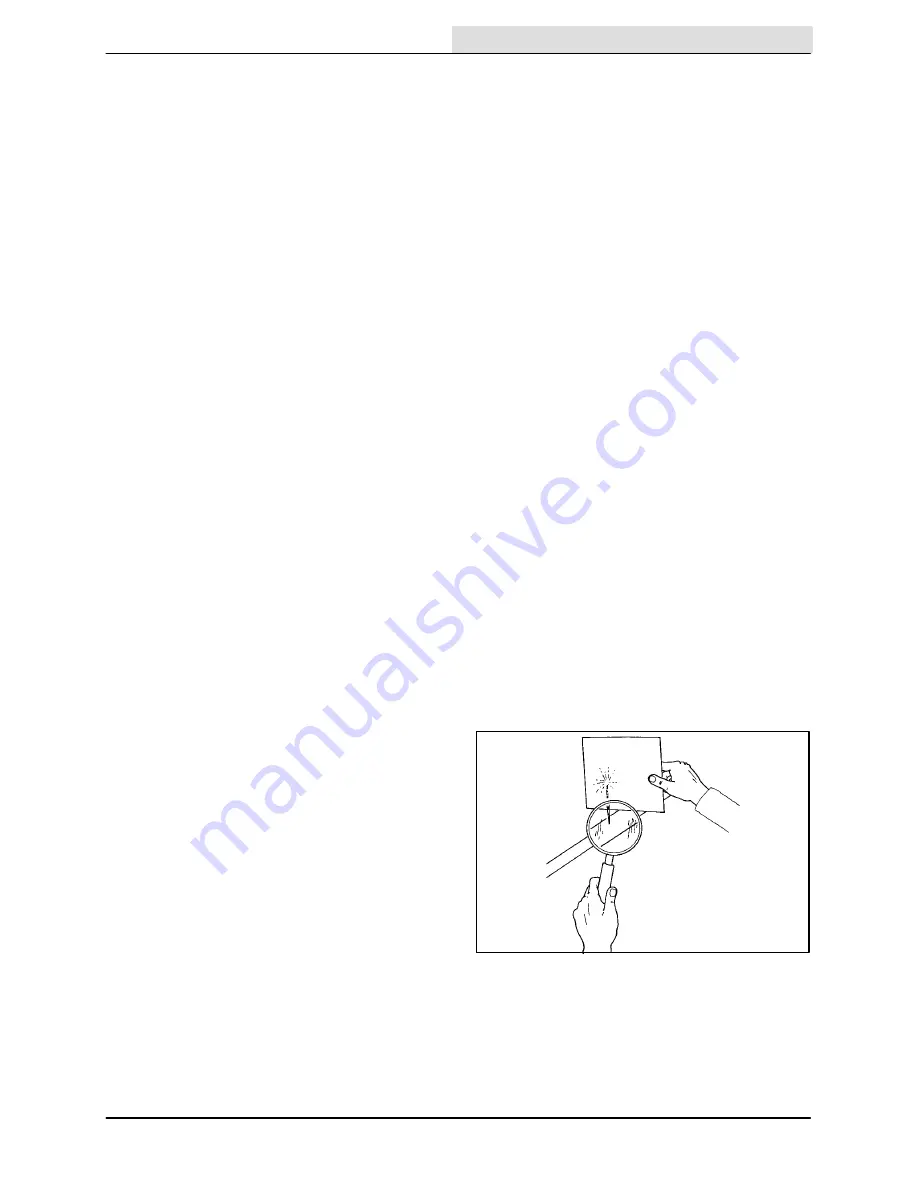

Fluid escaping at high pressure from a very small

hole can be almost invisible, and can cause

serious injuries.

See a doctor at once if injury results from

escaping hydraulic fluid. Serious infection or

reaction can develop if proper medical treatment

is not given immediately.

FOR SAFETY: When servicing machine,

use cardboard to locate leaking

hydraulic fluid under pressure.

If you discover a fluid leak, contact your

mechanic/supervisor.

PROPELLING MOTOR

Torque the shaft nut to 508 Nm (375 ft lb)

lubricated, 644 Nm (475 ft lb) dry after the first

50-hours of operation, and every 800 hours there

after.

00002