MAINTENANCE

95GR MM199 (10---89)

3-20

NOTE: No attempt should be made to adjust the

injection pressure without a proper testing pump and

pressure gauge. It is impossible to adjust the setting

of the injector with any degree of accuracy without

proper equipment.

WARNING: Do not start the engine with

loose injector securing nuts; this may result

in the injector flying out.

PRIMING THE FUEL SYSTEM

Priming is necessary on initial installation of the fuel

injection system, after any subsequent removal, or if

the system was drained by running out of fuel.

Before priming and venting, ensure that the outside

of the vent screws and surrounding area is

thoroughly clean to prevent dirt and foreign matter

entering the system.

NOTE: Electrical equipment such as starters should

be shielded during priming to prevent fuel entry.

Carry out steps 1 and 2 while operating the fuel lift

pump priming lever.

1. Operate the fuel lift pump priming lever and

loosen the filter outlet connection until fuel

flows free of air.

A

B

C

D

01475

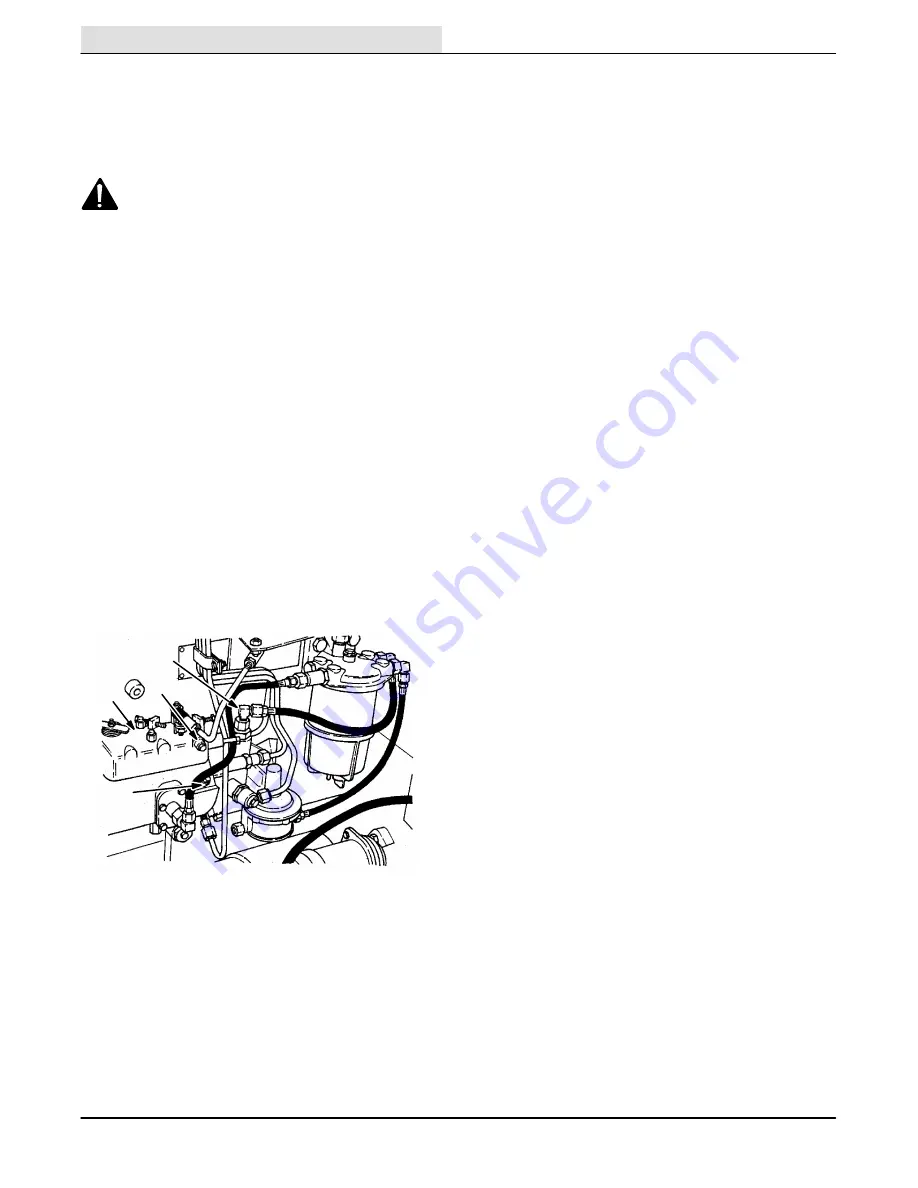

INJECTION PUMP VENTS

A. Injection Pump

B. Top Vent Valve

C. Fuel Pump Inlet

D. Governor Housing Vent Connection

2. Continue operating the fuel lift pump priming

lever while loosening the top vent valve and the

vent screw on the governor housing. When fuel

flows free of air, tighten the connections. Stop

operating the priming lever and place it in the

vertical position.

NOTE: Leaving the priming lever in the horizontal

position will lock the pump action stopping the fuel

supply.

3. Loosen any two injector high pressure pipe

nuts at the injector end. Set the accelerator to

the fully “open” position and ensure that the

stop control is in the “run” position. Crank

engine until fuel is free of air bubbles. Tighten

nuts.

NOTE: The bleeding operation may take a

considerable amount of cranking with the starter to

purge all air. It is important that the battery be in good

operating condition when bleeding.

If the engine will not start after bleeding, or any other

time, it may be an indication of a low battery charge.

If the voltage to the fuel shutoff solenoid falls below 8

volts, the valve will shut off fuel to the engine. This

may happen during cranking if the battery charge is

low. The condition may not be readily apparent since

cranking speed might still be good.

4. Start the engine.

Summary of Contents for 96GR

Page 1: ... Operator Manual ...

Page 12: ...SPECIFICATIONS 95GR MM199 10 89 1 2 ...

Page 16: ...SPECIFICATIONS 95GR MM199 10 89 1 6 ...

Page 18: ...OPERATION 95GR MM199 10 89 2 2 ...

Page 36: ...OPERATION 95GR MM199 10 89 2 20 ...

Page 47: ...MAINTENANCE 3 11 95GR MM199 10 89 04307 HYDRAULIC SCHEMATIC ...

Page 60: ...MAINTENANCE 95GR MM199 10 89 3 24 04309 ELECTRICAL SCHEMATIC ...

Page 61: ...MAINTENANCE 3 25 95GR MM199 10 89 01502 ELECTRICAL SCHEMATIC ACCESSORIES ...

Page 82: ...APPENDIX 95GR MM199 10 89 4 2 ...