OPERATION

EN

9

EX--SC--716 (04--10)

2. Pull the T--handle on drain valve to empty dirty

water (Figure 10).

FIG. 10

3. Close drain valve before continuing operation.

DRAINING LEFTOVER CLEANING SOLUTION

When finished cleaning, use the 1 m (3 ft) clean-out

hose to vacuum out the remaining water from solution

tank.

1. Connect the clean--out hose to recovery tank dome

(Figure 11).

FIG. 11

2. Turn the Master Pump Extension Tool switch on

and vacuum out the remaining solution from the

tank.

3. Drain recovery tank.

MACHINE MAINTENANCE

To keep machine in good working condition, simply

follow machine’s daily and monthly maintenance

procedures.

WARNING: Electrical Hazard. Unplug power

Cord Before Servicing Machine.

Contact an Authorized Service Center for machine

repairs.

FOR SAFETY: When servicing machine, all repairs

must be performed by a qualified service person.

DAILY MAINTENANCE

(After Every Use)

1. Drain and rinse out tanks thoroughly (See Draining

Tanks).

2. Rinse out the recovery tank dome.

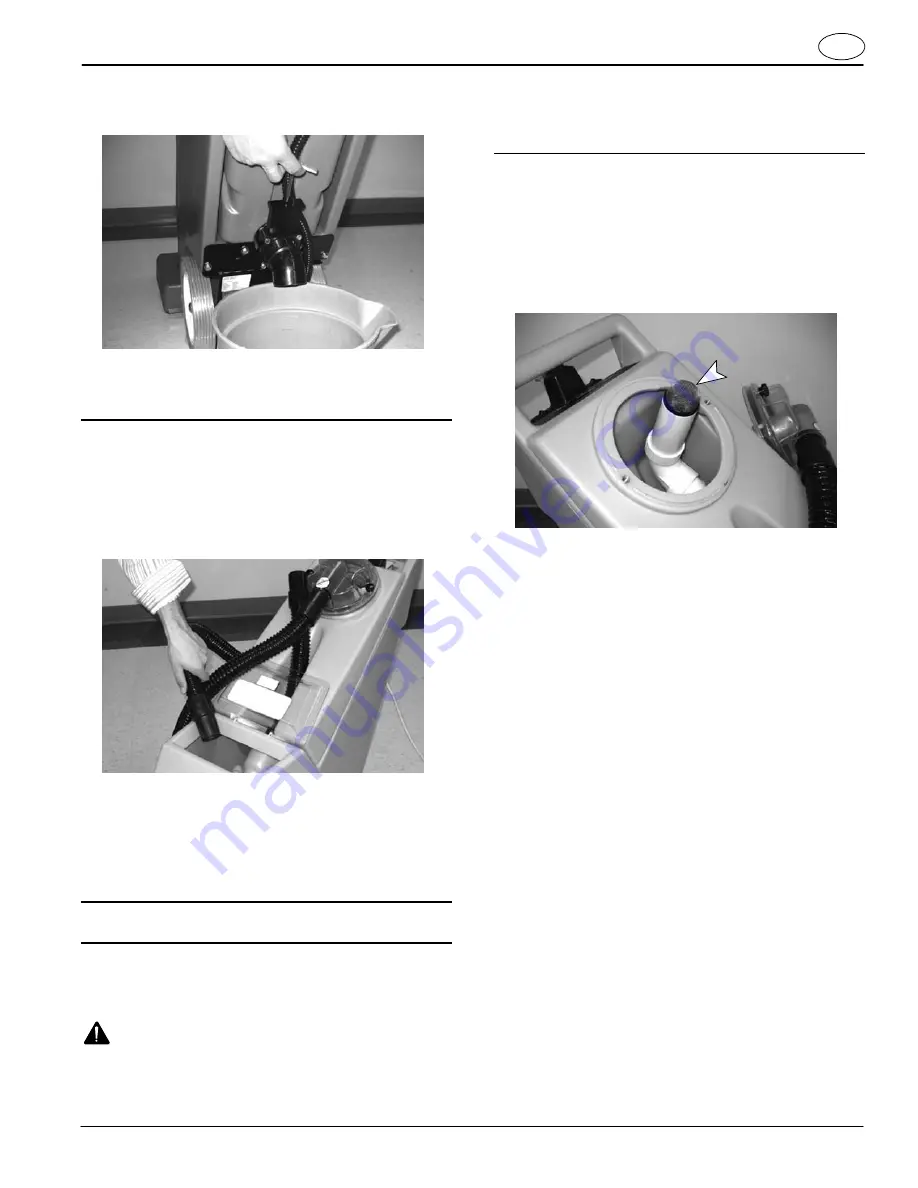

3. Remove recovery tank screen and clean (Figure

12).

FIG. 12

4. Remove and clean the two tank screens located in

the bottom of the solution tank.

5. Remove any entangled carpet fibers and debris in

brush.

6. Remove any clogged debris in vacuum head.

7. Check power cord for damage, replace if damaged.

Coil cord neatly after each use.

If the supply cord is damaged or broken, it must be

replaced by the manufacturer or it’s service agent

or a similarly qualified person in order to avoid a

hazard.

8. Inspect spray pattern for plugging. If plugged,

remove spray tips and soak in acetic acid solution

for up to six hours. Do not use pointed objects to

unplug tips, damage will occur.

FOR SAFETY: When using machine, follow mixing

and handling instructions on chemical containers.

9. Clean machine with a nonabrasive, non--solvent

cleaner.

ATTENTION: Do not power spray or hose off

machine. Electrical component damage may result.