64

T380AMR 9020999 (08-2020)

MAINTENANCE

MAINTENANCE CHART

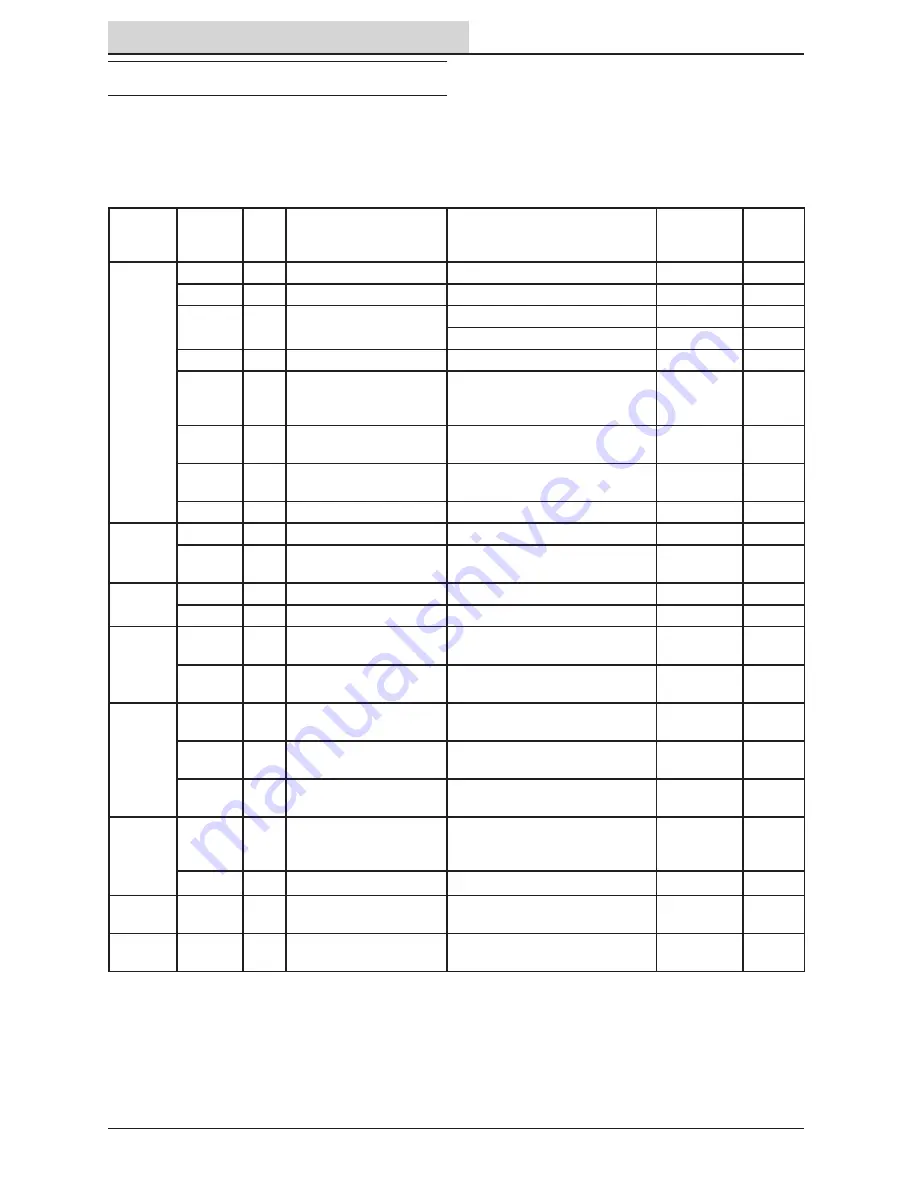

The table below indicates the Person Responsible

for each procedure.

O = Operator.

T = Trained Personnel.

Interval

Person

Resp.

Key

Description

Procedure

Lubricant/

Fluid

No. of

Service

Points

Daily

O

3

Pad

Check,

fl

ip or replace

1

O

3

Scrub brush

Check for damage, wear, debris

1

O

1

Squeegee

Check,

fl

ip or replace

-

3

Check de

fl

ection and leveling

-

6

O

8

Scrub head

fl

oor skirt

Check for damage and wear

1

O

2

Front/side 2D and 3D

sensors and upper/

lower LIDAR sensors

Check for damage. Clean with

provided micro

fi

ber cloth

-

8

O

4

Perimeter guards (left,

right, and front)

Check for debris, damage, and

wear

-

3

O

5

Recovery tank

Clean tank, screen

fi

lter, basket,

vacuum hose, and

fl

oat sensor

-

5

O

6

Solution tank

Drain and rinse as necessary

-

1

Weekly

O

7

Battery cells

Check electrolyte level

DW

18

T

4

Front perimeter guard

Inspect adjustment plates for

slipping. Adjust as necessary

1

50 Hours

O

5

Recovery tank lid seal

Check for wear and damage

1

O

15

Solution tank in-line

fi

lter Remove and clean

-

1

100

Hours

T

9

Vacuum fan seal and

squeegee seal

Check for damage and wear

-

2

O

7

Battery watering system

(option)

Check hoses for damage and

wear

-

All

200

Hours

T

7

Battery terminals and

cables

Check and clean

-

12

T

13

Steering gear chain

Lubricate, check tension, and

check for damage and wear.

GL

1

T

14

Steering u-joint

Lubricate and check for damage

and wear.

GL

1

500

Hours

T

11

Propelling motor

Check carbon brushes

(Check every 100 hours after

initial 500 hour check)

-

1

O

12

Tires

Check for damage and wear

-

3

750

Hours

T

9

Vacuum fan motor(s)

Replace carbon brushes

-

1

1250

Hours

T

10

Scrub brush motors

Replace carbon brushes

-

1

LUBRICANT/FLUID

DW Distilled

water

GL

SAE 90 weight gear lubricant