PLDC04453

REVISION 00

December 23, 2020

TECHNICAL OFFICE

Stavale

9

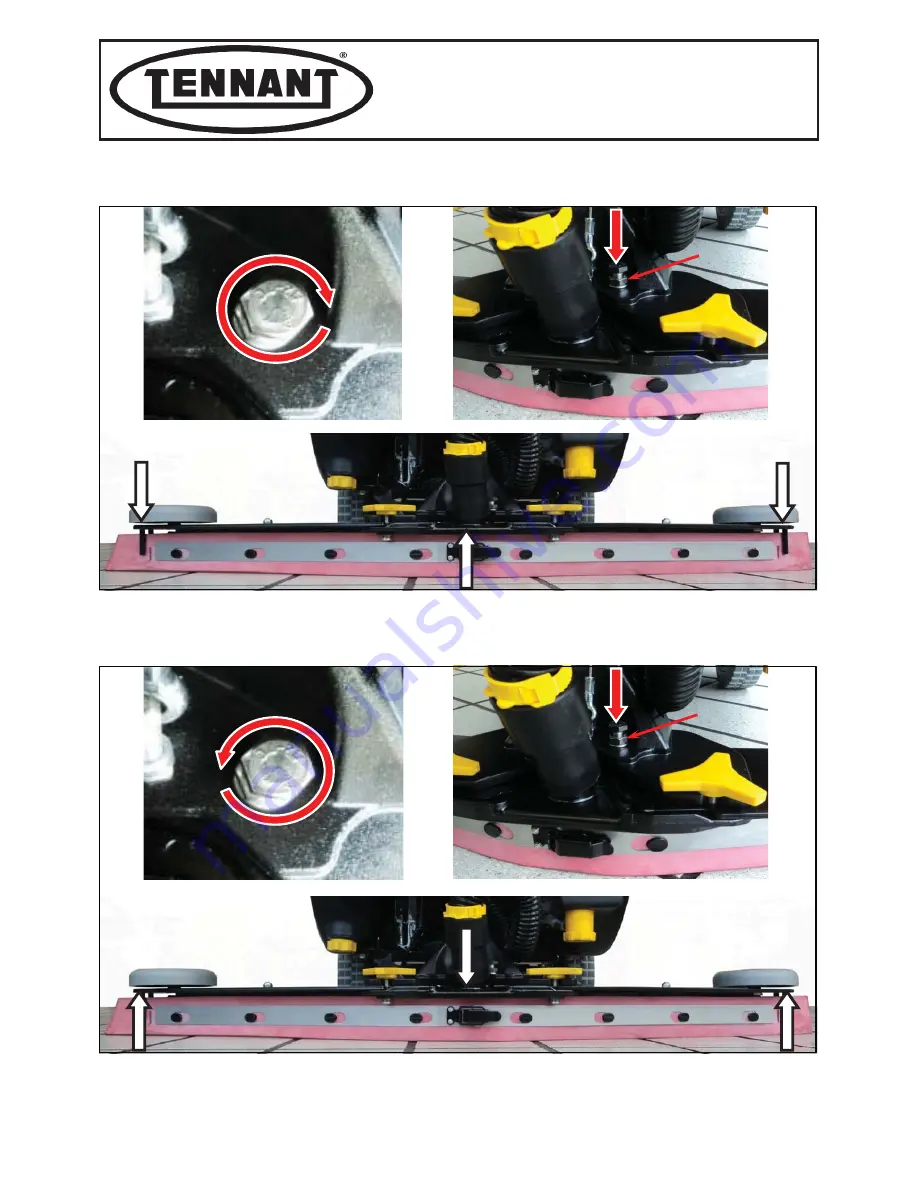

Screwing the screw

A

, the squeegee support lowers the edges of the squeegee, increasing

the deflection (compression) on the blade at the sides of the squeegee, taking deflection off the centre.

10

Unscrewing the bolt

A

, the squeegee support rais the edges of the squeegee, decreasing

the deflection on the blade at the sides of the squeegee and it increasing deflection on the centre.

11

Once having found the right angle, when the squeegee is perfectly parallel to the flooring,

hold screw

A i

n place lock the position with the nut

C

.

C

C

Fig. 35

Fig. 36

21 of 73