50

T500 9015504 01-2018

TROUBLESHOOTING

BDI (Battery

Discharge

Indicator)

☼

= Flashing

Pro-Panel

LCD

Faults

(Option)

Fault Condition

Reason

Correction

●

☼

☼

☼

●

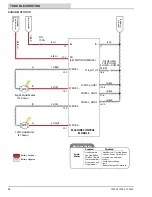

0xFF20

Scrub Controller CAN

Communication Fault

1. Control boards are not communicat-

ing properly.

2. Board lost power (wiring issue).

3. Control board may be damaged.

1. Power cycle machine.

2. No communication with

a network module. Use

CANopen troubleshooting

techniques.

0x0B04

Battery Watering CAN

Communication Fault

1. Control boards are not communicat-

ing properly.

2. Board lost power (wiring issue).

3. Control board may be damaged.

1. Power cycle machine.

2. No communication with a

network module. Use CANo-

pen troubleshooting tech-

niques.

0x0704

ec-H2O CAN Commu-

nication Fault

1. Control boards are not communicat-

ing properly.

2. Board lost power (wiring issue)

3. Control board may be damaged.

4. ec-H2O connector unplugged

(never plugged in).

5. ec-H2O connector pin 2 or 3 discon-

nected.

6. ec-H2O connector power pin dis-

connected.

1. Power cycle machine. If

fault persists, contact service.

2. No communication with a

network module.

3. Check connections.

☼

☼

☼

●

●

0xF104

Charger Timer Phase

I Warning

1. Batteries not able to be charged

correctly.

●

☼

☼

●

●

0xF101

Charger No Load

Warning

1. Battery pack may not be plugged

into charger.

Check battery wires and con-

nections.

●

☼

●

●

●

0xF102

Charger

Overheat

Warning

1. Charger environment is not cool

enough and cannot complete charge.

Move machine to well-ventilat-

ed area.

☼

●

☼

●

●

0x0703

ec-H2O Breaker

Tripped Warning

1. Detected module circuit breaker trip.

2. Scrub Controller board J4 connector

unplugged.

3. Scrub Controller board J4 connector

pin 2 disconnected.

Power cycle machine.

0x0712

ec-H2O Pump Break-

er Tripped Warning

1. Detected module circuit breaker trip.

2. Scrub Controller board J4 connector

unplugged.

3. Scrub Controller board J4 connector

pin 1 disconnected.

Power cycle machine. Check

connections and wiring.

☼

☼

☼

☼

●

0x0704

ec-H2O CAN Commu-

nication Fault

1. Control boards are not communicat-

ing properly.

2. Board lost power (wiring issue)

3. Control board may be damaged.

4. ecH2O connector unplugged (never

plugged in).

5. ecH2O connector pin 2 or 3 discon-

nected.

6. ecH2O connector power pin discon-

nected.

1. Power cycle machine.

2. No communication with a

network module.

3. Check connections.

●

☼

●

☼

●

0x0711

ec-H2O Pump Open

Warning

1. Wiring, connector or control board

issue on the ec-H2O pump.

Control board is not detecting

pump current. Check connec-

tions for voltage and verify

pump is operating.

Summary of Contents for t500

Page 5: ...5 T500 9015504 01 2018 CONTENTS ...

Page 55: ...55 T500 9015504 01 2018 TROUBLESHOOTING ...

Page 89: ...89 T500 9015504 01 2018 SERVICE 9 Cycle the key switch to save selections ...

Page 111: ...111 T500 9015504 01 2018 SERVICE ...

Page 117: ...117 T500 9015504 01 2018 SERVICE ...

Page 146: ...146 T500 9015504 01 2018 SERVICE ...