MAINTENANCE

Tennant T600 EE (04-2018)

35

4. Rotate the rear blade to a new wiping edge and

reinstall blade (Figure 78). Make sure to align the

slots in the blade with retainer tabs.

FIG. 78

5. Squeeze the squeegee frame and blade retainer

together and re-tighten the two outside knobs

(Figure 79).

FIG. 79

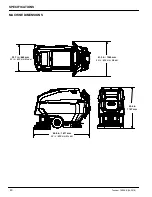

MACHINE JACKING

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, turn off machine and remove

key.

Use the designated locations to jack up the machine for

service (Figure 80). Empty the recovery and solution

tanks and position the machine on a level surface

before jacking. Stay clear from the solution tank filter

bowl when jacking.

FOR SAFETY: When servicing machine, jack

machine up at designated locations only. Support

machine with jack stands. Use jack or hoist that

will support the weight of the machine.

FIG. 80

PUSHING AND TRANSPORTING MACHINE

PUSHING MACHINE

If the machine becomes disabled, it can be pushed as

describe below.

Only push the machine for a very short distance and do

not exceed 3.2 kp/h (2 mph). It is not intended to be

pushed for a long distance or at a high speed.

For models equipped with an electronic parking brake

system, the brake must be disengaged before pushing

machine. To disengage brake, position the brake lever

on the transaxle to the down position (Figure 81).

FIG. 81

ATTENTION: Do not push machine for a long

distance or damage may occur to the propelling

system.

Immediately after pushing the machine, re- engage the

brake lever to prevent a roll hazard.

NOTE: When brake lever is disengaged, the propel will

be disabled and a fault will be detected until lever is

re-engaged.

FOR SAFETY: When servicing machine, do not

push the machine on inclines with brake disabled.