14

SET

UP

CODE DOWN

SET

UP

CODE DOWN

SET

UP

CODE DOWN

SET

UP

CODE DOWN

SET

UP

CODE DOWN

5.5 Auto closing

5.6 Photocells

For the automatic closing function to work properly, photocells must be

installed.

Make sure that the photocells are properly connected. Use a NC photocell

(Fig. 15 and Fig. 16). The photocell function should be turned off when they

are not connected. Otherwise, it will not be possible to close the gate.

Press UP button to increase the time or

DOWN to decrease the time. The display

shows numbers from 0 to 9, where:

0 - auto closing function

is turned off,

1 - minimum closing time

it’s 15 seconds,

9 - maximum closing time

it’s 135 seconds.

Press the SET button

to confirm the settings.

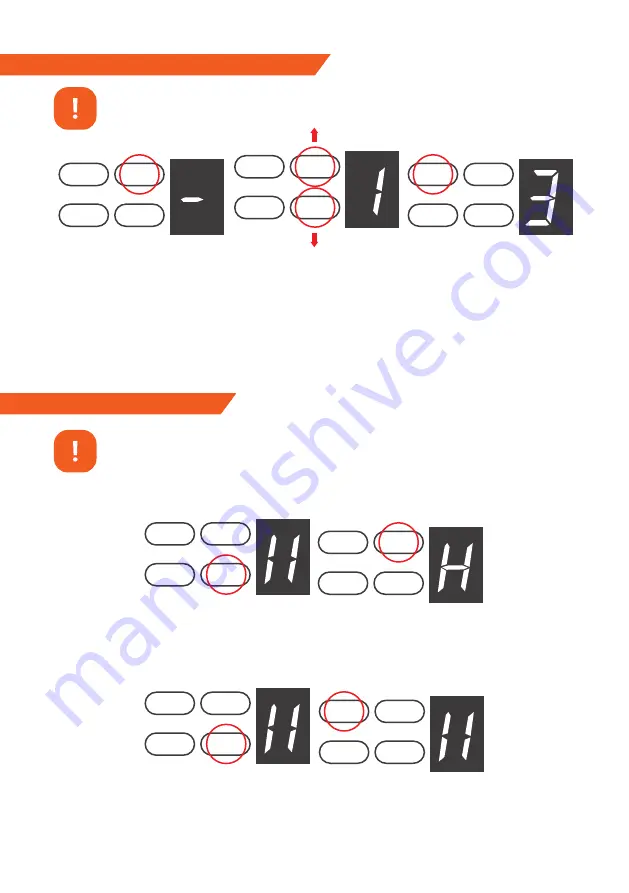

Press DOWN button to turn on

the photocells. The digit 11 appear.

Press and hold UP button until the digit

or horizontal bar appears. Press UP button

again to set the automatic closing time.

Press UP button to activate photocells.

The „H” symbol appears in the display.

Press and hold DOWN button

untill digit 11 or symbol „H” appear.

Press the SET button

to confirm the settings.

SET

UP

CODE DOWN

SET

UP

CODE DOWN