Part No. 40462

DPL-25S • DPL-30S • DPL-35S Super Series

3 - 5

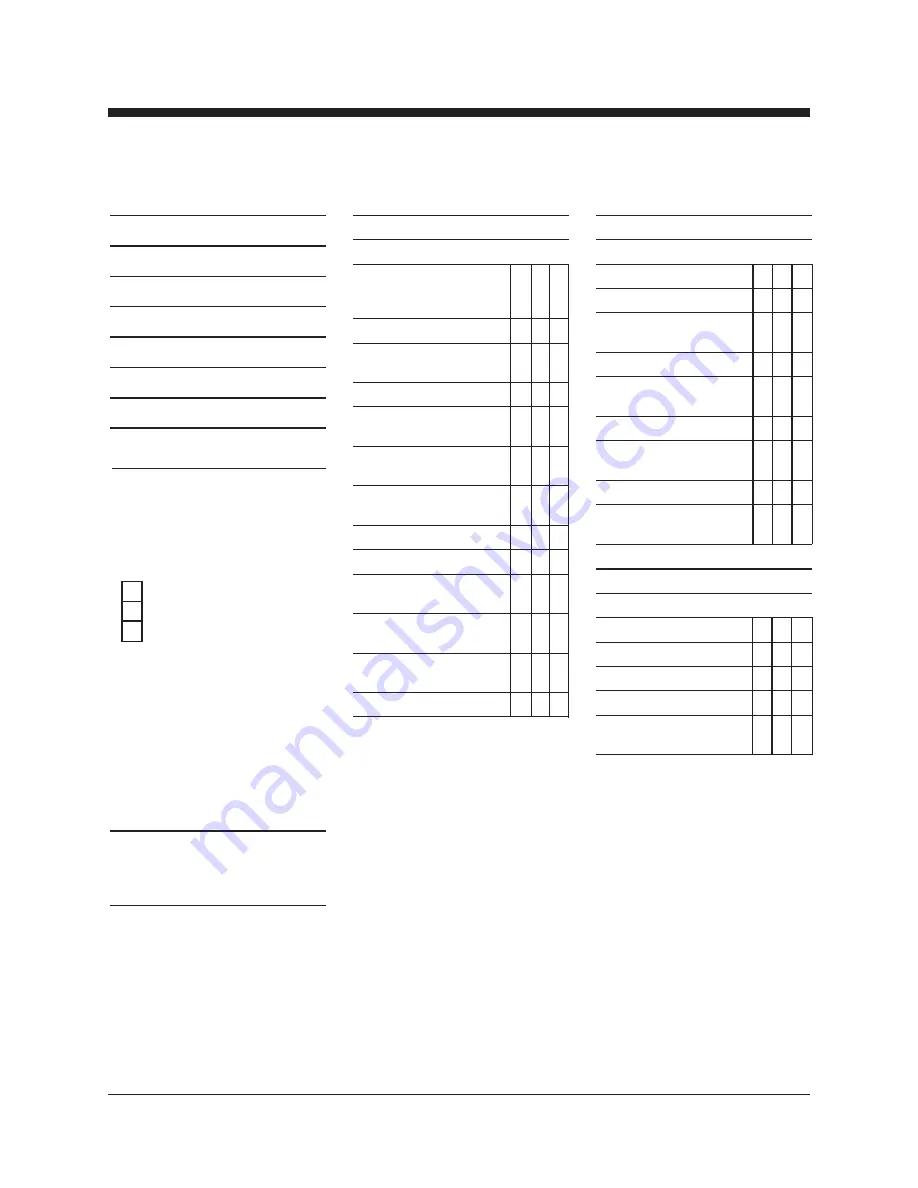

Section 3 - Scheduled Maintenance Inspections

September 2016

Dealer

service

suggested

Tools are

required

New parts

required

Checklist B

Y N

R

Refer to Table B

B-1

Electrical wiring

B-2

Welds

B-3

Lifting chain

adjustments

B-4

Battery

B-5

Clean and lubricate

columns

B-6

Lifting capacity

B-7

Power to platform

operation

B-8

Sequencing cables

B-9

Proper outrigger

length

Checklist C

Y N

R

Refer to Table C

C-1

Casters and wheels

C-2

Mast assembly

C-3

Lifting chains

C-4

Hydraulic oil

C-5

Auxiliary platform

lowering batteries

Checklist A

Y N

R

Refer to Table A

A-1

Operator's

and Responsibility

manuals

A-2

Decals and placards

A-3

Damage, loose or

missing parts

A-4

Hydraulic leaks

A-5

Auxiliary lowering

operation

A-6

Manual lowering

operation

A-7

Battery and charger

- DC models

A-8

Columns

A-9

Sequencing cables

A-10 Interlock system

operation

A-11 Power and

function controls

A-12 Lifting chains

and idler wheels

A-13 Breather cap

Maintenance Inspection Report

Model

Serial number

Date

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Instructions

• Make copies of this page to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection to be

performed.

Daily Inspection: A

Quarterly Inspection: A+B

Annual Inspection: A+B+C

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Use the maintenance tables in this

section and the step-by-step

procedures in section 4 to learn how to

perform these inspections.

• If any inspection receives an “N”,

remove the machine from use, repair

and re-inspect it. After repair, place a

check in the “R” box.

Legend

Y = yes, acceptable

N = no, unacceptable

R = repaired

Comments