4 - 6

DPL-25S • DPL-30S • DPL-35S Super Series

Part No. 40462

September 2016

Section 4 - Scheduled Maintenance Procedures

A-12

Inspect the Lifting Chains and

Idler Wheels

Maintaining the lifting chains and idler wheels in

good condition is essential to safe machine

operation. Failure to find and replace damaged

chains or idler wheels could result in unsafe

operating conditions and may cause component

damage.

1 Raise the platform approximately 3 feet (1 m).

2 Visually inspect the chains and idler wheels

near the top of each column for the following:

• Excessive corrosion or contamination

• Broken or missing chain leafs and pins

• Tight or kinked joints in the chain

• Missing or damaged idler wheels and related

components

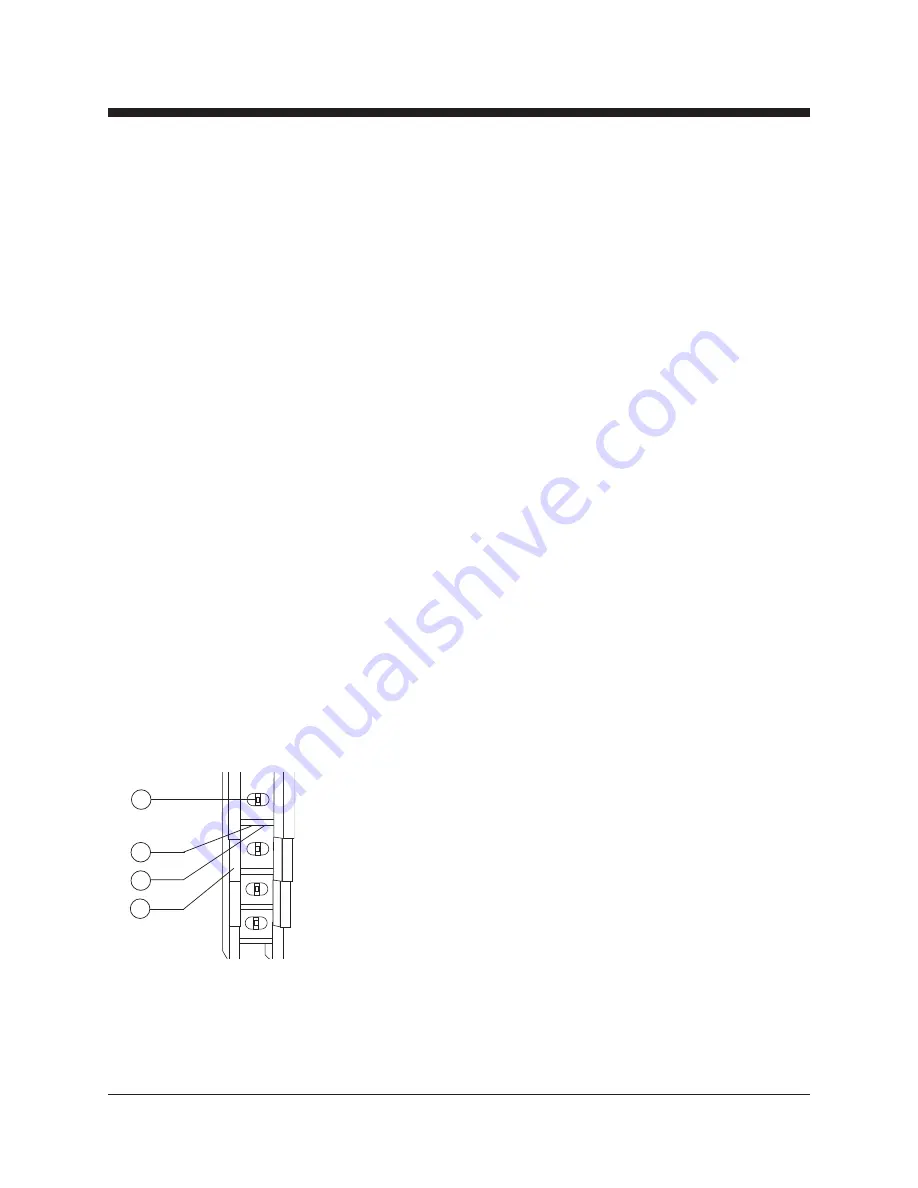

3 Inspect the chain terminations near the bottom

of each column to confirm that each termination

has a lock nut.

4 Inspect the chain terminations near the bottom

of each column to confirm that the chain

tensioner bracket is centered in the inspection

hole.

a

chain tensioner bracket

b

adjustment nut (hidden from view)

c

termination rod (hidden from view)

d

column

TABLE

A

PROCEDURES

A-13

Inspect the Breather Cap

The hydraulic reservoir is a breathing-type

reservoir. The breather cap has an internal air filter

that can clog and may cause the power unit to

operate improperly. If the breather cap is not

properly installed and checked daily, impurities can

enter the hydraulic system and cause component

damage.

1 Be sure the breather cap is installed on the

hydraulic power unit reservoir and is not

damaged. Do not remove it.

c

a

b

d