4 - 12

DPL-25S • DPL-30S • DPL-35S Super Series

Part No. 40462

September 2016

Section 4 - Scheduled Maintenance Procedures

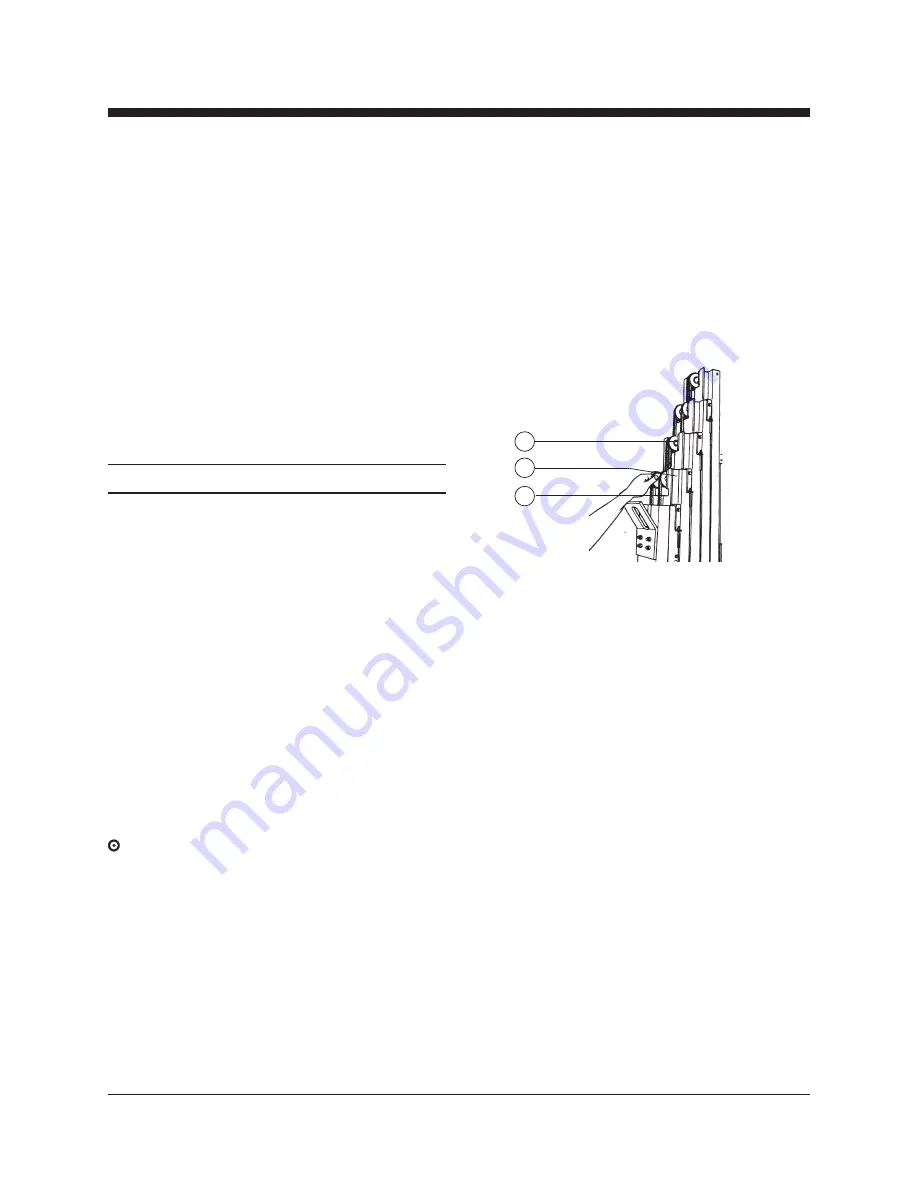

5 Inspect each idler wheel for the following:

• Excessive wear on the side flanges

• Unusual wear

• Movement side to side in excess of

0.040 inches (1 mm)

• Any movement of wheel front to back

a

idler wheel

b

spacer

c

lifting chain

Note: If idler wheel inspection results in a

measurement that is not within specification, refer

to Repair procedure 5-2,

How to Assemble the

Mast.

6 Adjust the sequencing cables. See B-8,

Adjust

the Sequencing Cables.

c

a

b

C-1

Inspect and Lubricate the Casters

Extremely dirty conditions may require that the

casters be inspected and lubricated more often.

1 Visually inspect each caster for cuts, cracks or

unusual wear.

2 Move the machine on a flat smooth surface and

check that the casters roll smoothly.

3 Pump grease into the caster until it can be seen

coming out of the bearing seal gap.

Grease Type

Lithium-based

C-2

Inspect the Mast Assemblies

for Wear

Detection of excessive or unusual wear in the mast

assembly is essential for safe machine operation.

An unsafe working condition exists if the mast

assembly has excessive wear and/or does not

operate smoothly, free of hesitation and binding.

1 Raise the platform until 3 to 5 inches (7.6 to

12.7 cm) of the top of each column is visible.

2 Visually inspect the top of each column for

clearance between the roller wheels and the

adjacent column surface.

Result: There should be a equal amount of

distance between the roller wheel and the

column on each side.

Note: If mast inspection results in a measurement

that is not within specification, refer to Repair

procedure 5-4,

How to Adjust the Glide Pads.

3 Loosen but do not remove the adjustment nut on

the sequencing cable.

4 Raise the platform approximately 3 feet (1 m).

Table C Procedures