4.

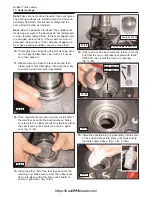

Use an open end or pipe wrench to turn and

remove the end gland. (figure 16-2)

5.

Use a pry bar or similar device to pull the rod and

piston from the cylinder. (figure 16-3)

6.

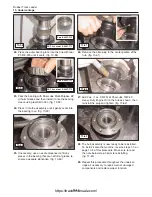

Inspect the piston surface, seals and ring for wear

or damage. If any component appears to be dam-

aged in any way, replace it. When inspecting the

piston surface, look for scratches. If any are pres-

ent that are deep enough to catch with your finger-

nail, the piston should be replaced. (figure 16-4)

Note:

Seal imperfections or scratches on the piston, bore or

rod or will cause internal/external leakage and impaired func-

tion. Defective components must be repaired or replaced.

7.

With the piston and rod removed from the cylinder,

inspect the cylinder bore for scratches or other

damage. If any are present that are deep enough

to catch with your fingernail, the cylinder tube

weldment should be replaced. (figure 16-5)

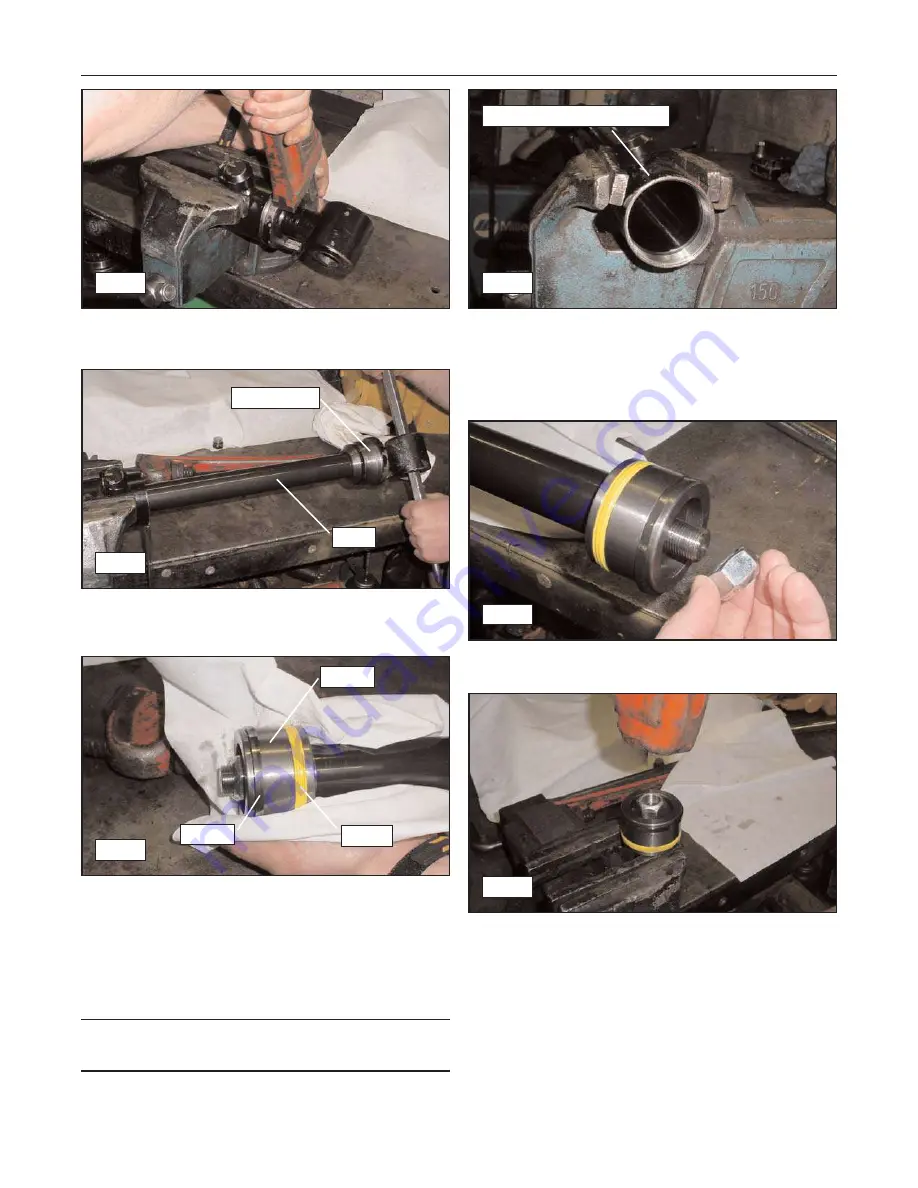

8.

Remove the nut from the rod end. (figure 16-6)

9.

Support the piston loosely from the underside (fig-

ure 16-7), thread the nut partially on to protect the

threads and tap the rod end with a rubber or dead

blow hammer to free the piston from the rod.

10.

Once loose, remove the nut and piston from the

rod.

16-2

Rubber Track Loader

16. Hydraulic Component Service

16-2

16-3

16-4

16-5

16-6

16-7

End Gland

Rod

Piston

Seals

Ring

Cylinder Tube Weldment

https://tractormanualz.com/

Summary of Contents for ASV SR70

Page 5: ...IV https tractormanualz com...

Page 11: ...1 6 https tractormanualz com...

Page 41: ...4 20 https tractormanualz com...

Page 87: ...12 8 https tractormanualz com...

Page 105: ...14 6 https tractormanualz com...

Page 109: ...15 4 https tractormanualz com...

Page 125: ...16 16 https tractormanualz com...

Page 133: ...17 8 https tractormanualz com...

Page 137: ...18 4 https tractormanualz com...

Page 139: ...19 2 https tractormanualz com...