Service and Repair Manual

March 2021

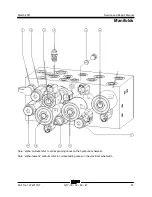

Hydraulic Pump

52

GS

™

-30 • 32 • 46 • 47

Part No. 1272217GT

4-1

Function Pump

The hydraulic pump is attached to the motor which

makes up the hydraulic power unit.

How to Test the Hydraulic Pump

Note: When removing a hose assembly or fitting,

the O-ring (if equipped) on the fitting and/or hose

end must be replaced. All connections must be

torqued to specification during installation. Refer to

Specifications,

Hydraulic Hose and Fitting Torque

Specifications.

Component damage hazard.

The work area and surfaces

where this procedure will be

performed must be clean and

free of debris that could get into

the hydraulic system.

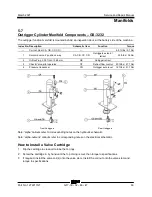

1 Tag, disconnect and plug the high pressure

hydraulic hose from the hydraulic pump.

2 Connect a 0 to 5000 psi / 0 to 350 bar

pressure gauge to the high pressure port on

the pump.

3 Turn the key switch to ground control and pull

out the red Emergency Stop button to the on

position at both ground and platform controls.

4 Activate the platform up function from the

ground controls.

Result: If the pressure gauge reads 3200 psi /

221 bar, immediately stop. The pump is good.

Result: If the pressure gauge fails to reach

3200 psi / 221 bar, the pump is bad and will

need to be serviced or replaced.

Component damage hazard.

There is no relief valve in the

hydraulic pump and the pump

can be damaged if the pressure

is allowed to exceed

3200 psi / 221 bar. When testing

the pump, activate the pump in

one second intervals until

3200 psi / 221 bar is confirmed.

Do not over-pressurize the

pump.

5 Remove the pressure gauge and reconnect

the hydraulic hose. Torque to specifications.