Service and Repair Manual

June 2021

Manifolds

90

GS

™

-84 • GS

™

-90

Part No. 1306587GT

11 Adjust the internal hex socket. Turn it

clockwise to increase the pressure or

counterclockwise to decrease the pressure.

Install the relief valve cap.

12 Repeat this procedure beginning with step 7.

13 Fully lower the platform.

14 Using a suitable lifting device, add an

additional weight to the platform not to exceed

20% of the maximum rated work load at full

height. Secure the weight to the platform.

Refer to the specifications below.

Additional test weight

GS-3384 and GS-3390

500 lbs

227 kg

GS-4390

(most models - refer to capacity indicator

decal)

375 lbs

170 kg

GS-4390

(some models - refer to capacity indicator

decal)

450 lbs

204 kg

GS-5390

375 lbs

170 kg

15 Activate the platform up function and attempt

to raise the platform.

Result: The platform does not raise. Proceed

to step 21.

Result: The platform lifts. Proceed to step 16.

16 Lower the platform to the stowed position.

17 Turn the machine off. Hold the system relief

valve with a wrench and remove the cap.

18 Adjust the internal hex socket. Turn it

counterclockwise to decrease the pressure.

Install the relief valve cap.

19 Start the engine.

20 Repeat this procedure beginning with step 15.

21 Turn the machine off and remove the weight

from the platform.

How to Adjust the Steer Relief Valve

How to Adjust the Steer Relief

Valve

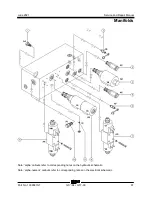

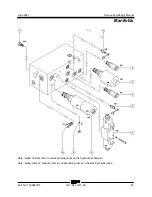

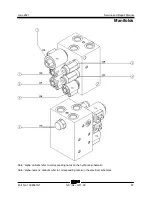

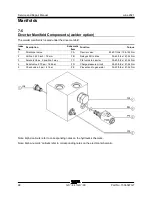

Note: Refer to Function Manifold Component list to

locate the steer relief valve.

1 Connect a 0 to 3000 psi / 0 to 250 bar

pressure gauge to the test port (item AB) on

the function manifold.

2 Start the engine from the platform controls.

3 Press and hold the function enable switch and

hold the steer thumb rocker switch in the right

direction. Allow the wheels to completely turn

to the right, then continue holding the switch

while observing the pressure reading on the

pressure gauge. Note the pressure. Refer to

Specifications,

Hydraulic Component

Specifications.

4 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item AE).

5 Adjust the internal hex socket. Turn it

clockwise to increase the pressure or

counterclockwise to decrease the pressure.

Install the relief valve cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

6 Repeat steps 2 through 3 to confirm the relief

valve pressure.

Summary of Contents for Genie GS-3384

Page 185: ...June 2021 Service and Repair Manual 171 Ford MSG 425 Engine Wire Harness...

Page 188: ...Service and Repair Manual June 2021 174 Deutz D 2 9 L4 Engine Wire Harness...

Page 189: ...June 2021 Service and Repair Manual 175 Deutz TD 2 2 L3 Engine Wire Harness...

Page 192: ...Service and Repair Manual June 2021 178 Deutz TD 2 2 L3 Engine Wire Harness...

Page 193: ...June 2021 Service and Repair Manual 179 Hydraulic Schematic...

Page 194: ...Service and Repair Manual June 2021 180 GS 84 GS 90 Part No 1306587GT Hydraulic Schematic...

Page 195: ...June 2021 Service and Repair Manual Part No 1306587GT GS 84 GS 90 181 Hydraulic Schematic...

Page 196: ...Service and Repair Manual June 2021 182 Hydraulic Schematic...

Page 197: ...June 2021 Service and Repair Manual 183 Electrical Schematic Ford Engine Models ANSI CSA...

Page 200: ...Service and Repair Manual June 2021 186 Electrical Schematic Ford Engine Models ANSI CSA...

Page 201: ...June 2021 Service and Repair Manual 187 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 204: ...Service and Repair Manual June 2021 190 Electrical Schematic Deutz Engine Models ANSI CSA...

Page 206: ...Service and Repair Manual June 2021 192 Electrical Schematic SCON ANSI CSA...

Page 207: ...June 2021 Service and Repair Manual 193 Electrical Schematic Ford Engine Models AS CE...

Page 210: ...Service and Repair Manual June 2021 196 Electrical Schematic Ford Engine Models AS CE...

Page 211: ...June 2021 Service and Repair Manual 197 Electrical Schematic Deutz Engine Models AS CE...

Page 214: ...Service and Repair Manual June 2021 200 Electrical Schematic Deutz Engine Models AS CE...

Page 217: ......